Roll Grooving Machine For Cylinder Supercapacitor

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-HKZN-PT03-B1Payment:

Credit Card, Paypal, T/T , Western Union, LCShipping port:

Xiamen PortLead Time:

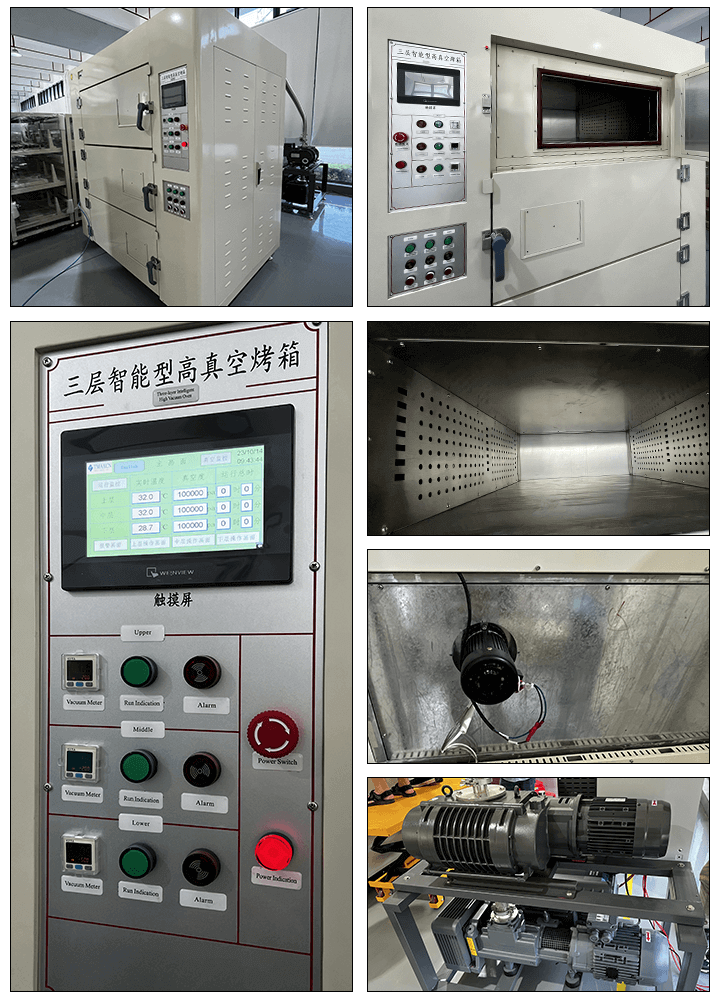

5 days3 Layers Vacuum Drying Oven for Supercapacitor Electrodes Manufacturing

1、Scope of oven use:

Suitable for baking lithium-ion battery electrodes, cells, and waiting liquid batteries

2、Configuration

A. Box: Made of 3.0mm imported 304 stainless steel, with reinforcing ribs made of the same material

B. Rack: Made of high-quality cold-rolled sheets of 1.5mm and 2.0mm, consisting of two layers of insulation. The cotton is made of three layered materials: aluminum silicate,aluminum foil cotton, and sound insulation cotton

C. Hot air system: Each layer is composed of fans, heating boxes, air ducts, air ducts, etc., which can better achieve temperature consistency

D. Control system: composed of PLC, touch screen, pressure sensor, high vacuum baffle valve, solid-state relay, temperature controller, electromagnetic valve group, etc

E. Hardware components: including doors, back covers, vacuum tubes, and other stamped parts, etc

3、Machine characteristics

L. Program interlocking prevents inter layer gas leakage.

4、Main parameters

|

1 |

Heating principle |

Three layer separate hot air external circulation heating |

|

2 |

Power source |

380V 50HZ 16KW |

|

3 |

Gas source |

Dry gas 0.1-0.2MPa/vacuum

-0.098-0.1Mpa/compressed gas 0.4-0.5MPa |

|

4 |

Temperature |

Room temperature to 150℃ |

|

5 |

Vacuum degree |

When drawn between -0.1-0.098Mpa, the digital display maintains a pressure of ≥ 95% for 24 hours |

|

6 |

Display error |

Set value and stable displayed value≤±0.1℃ |

|

7 |

Thermal insulation performance |

The outer wall temperature shall not exceed 45 degrees (excluding glass doors) |

|

8 |

Temperature

uniformity |

50MM away from the wall at each point inside the cavity: ≤ ± 3.5 ℃ under vacuum, ≤ ± 2.5 ℃ under normal pressure |

|

9 |

String temperature property |

≤20℃(Within 100 degrees of temperature rise in adjacent layers, only within 20 degrees higher than room temperature) |

|

10 |

Response speed |

The meter display reaches the set value within 30 minutes, and the temperature of the unloaded core stabilizes for 45-60 minutes |

|

11 |

Chamber size |

330H×830W×800D×3 |

|

12 |

Outer size |

1970H× 1250W× 1100D |

5、Electrical configuration:

|

SN |

Item |

Specification |

|

1 |

PLC |

Fujian Weikong |

|

2 |

Touch screen |

7-inch LCD maintenance color screen |

|

3 |

Temperature

controller |

Digital intelligent temperature

controller/microcomputer PID automatic calculation |

|

4 |

Temperature mode |

PID+SSR(thyristor), Shanghai Yatai |

|

5 |

Over temperature

protection |

Shanghai Yatai Temperature Controller |

|

6 |

Temperature sensor |

K-type thermocouple |

|

7 |

Vacuum gauge |

Digital vacuum gauge/- 101.0-101.0 kPa

positive and negative pressure universal type, Taiwan Jingdeng |

|

8 |

Vacuum

valve/nitrogen valve |

High vacuum baffle valve |

|

9 |

Alarm |

Sound and light alarm |

|

10 |

Heating tube |

Best |

|

11 |

Control mode |

Each studio works independently, and the heating, vacuuming, and nitrogen filling modes are PLC automatic circulation. The operation of each working section is set through the touch screen |

Online service

Online service +86 13174506016

+86 13174506016 Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8613174506016

+8613174506016