Supercapacitor Tabs Punching And Trimming Machine

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-MDA-8000BPayment:

Credit Card, Paypal, T/T , Western Union, LCShipping port:

Xiamen PortLead Time:

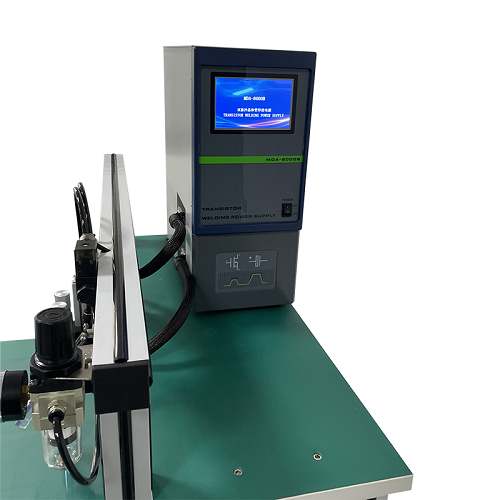

5 days8000A Transistor Power Supply Manual Spot Welding Machine For Battery Poles Welding

Introduction:

Transistor welding power supply is a high-precision, high-speed and high current transistor welding power supply that performs high-speed switching through the power switch tube and performs closed-loop feedback control on the voltage and current between welding electrodes collected in real time.

Main Function:

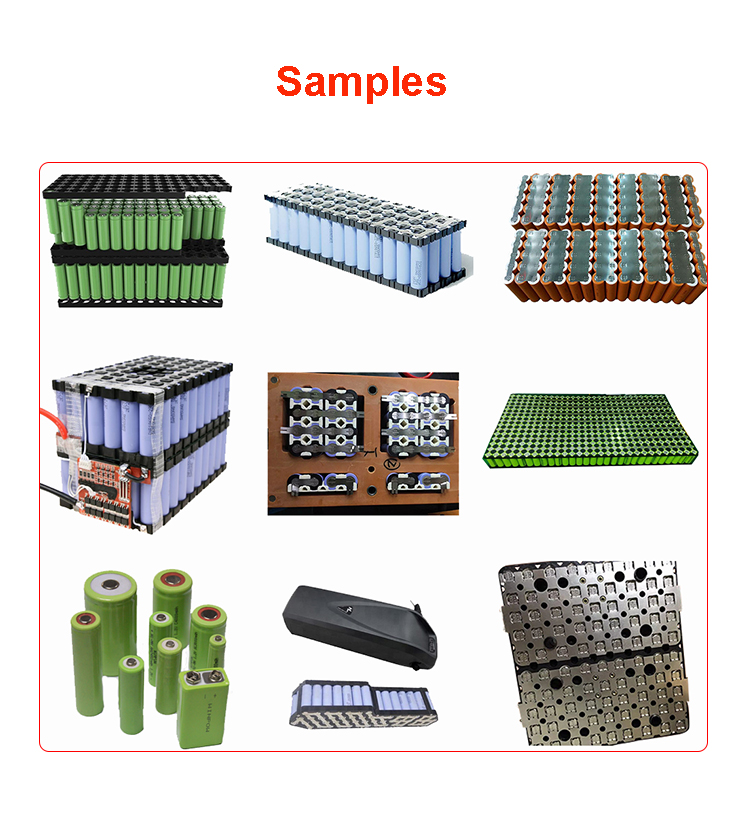

Cylindrical battery, Prismatic battery, Polymer battery Pneumatic spot welding with nickel sheet .

Product description:

1.The welding power supply adopts transistor switching mode, which can realize small and high-efficiency and high output precision welding.

2.The machine adopts three welding methods:

Constant voltage welding:Control the voltage between electrodes, the current is small, and spark will be reduced during welding;

3.Constant current welding:Through a certain amount of current, it has nothing to do with the resistance of the workpiece and can be welded stably;

4. Constant voltage and current welding:Welding is controlled by setting current and voltage at the same time.

5.Output current direction:

6.MDA-8000B current flows from the positive to the negative (unipolar welding), which is mainly suitable for power batteries;

Specification:

|

Supply voltage |

Single phase :AC100V- 120V or AC200V-240V 50/60Hz |

|

Spot welding power |

MDA-8000B Transistor spot welding power |

|

Welding output power |

Max 8000A |

|

Nickel strip thickness |

0.06-0.2mm nickel plated or pure nickel strip

0.21-0.4mm nickel strip requires bump welding |

|

Working way |

Pneumatic welding |

|

Welding platform |

L600mm*W300mm |

|

Parameter setting |

Touch way |

|

Power at 0.1% duty cycle |

SQ1=9KVA |

|

Power at 50% duty cycle |

S50=0.36KVA |

|

Communication interface |

RS485, RS232 |

|

Canonical storage quantity |

16 group |

|

Cooling mode |

Forced air cooling |

|

Relative temperature |

- 10-55C |

|

Machine Size |

L900*W900*H1350mm |

|

Welding power supply weight |

About 50kg |

Detail Show:

Online service

Online service +86 13174506016

+86 13174506016 Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8613174506016

+8613174506016