360mm Width Roll To Roll Intermittent Slot Die Coating Machine With Optional Oven Length

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-PCPLPayment:

Credit Card, Paypal, T/T , Western Union, LCLead Time:

5 daysAutomatic Pouch Cell Production Equipment Plant For Li-ion Battery Fabrication

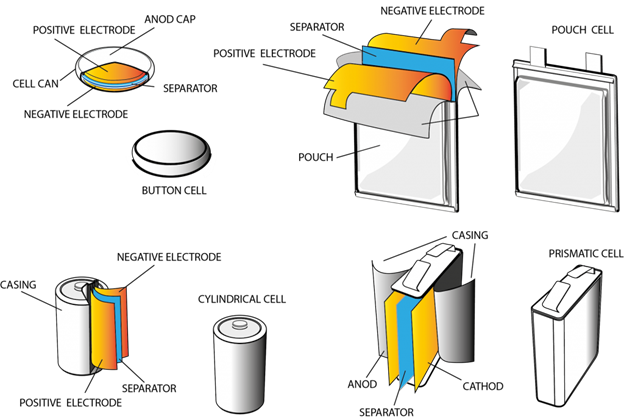

Structure of batteries

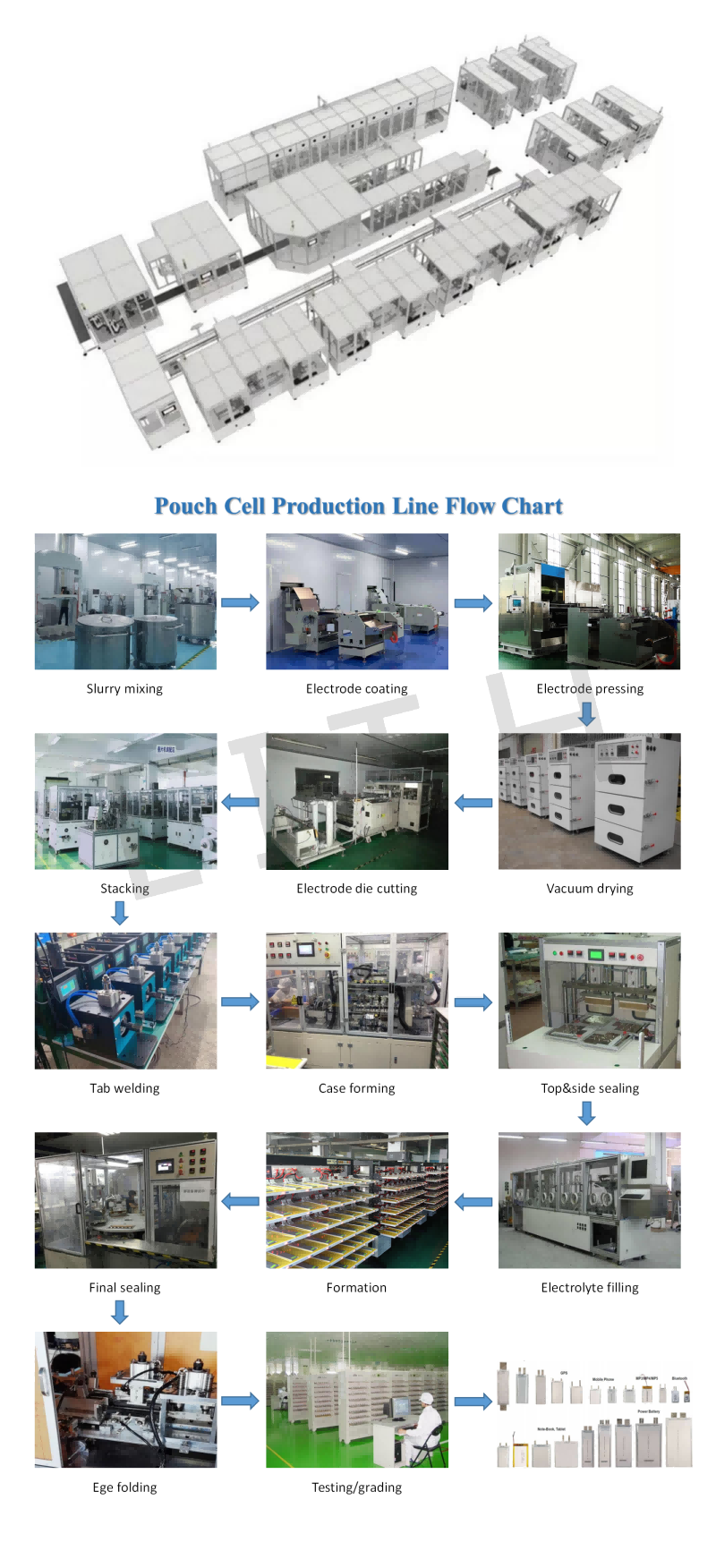

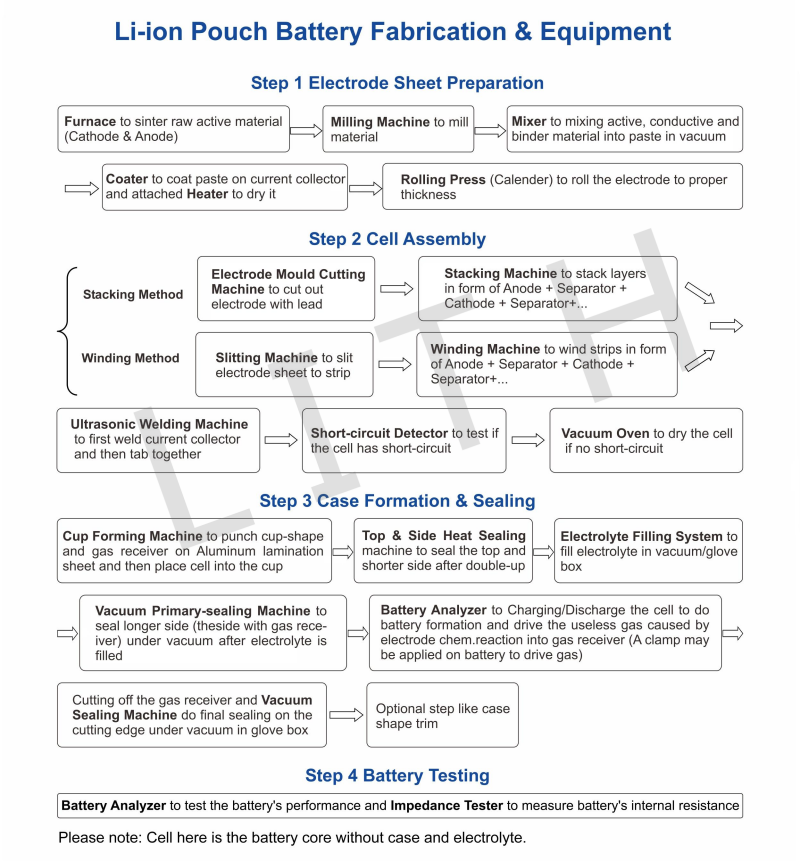

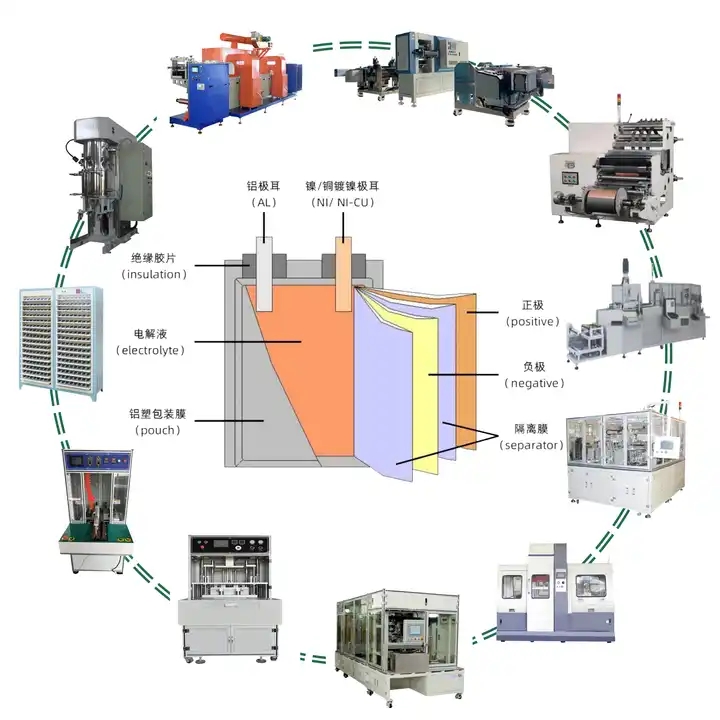

Pouch cell production line flow chart:

|

Process |

Detailed procedure |

Equipment Name |

Main Features |

|

Drying |

Raw material baking |

Vacuum oven |

450L, 3 layers, separate control |

|

Mixing |

Anode material mixing |

Vacuum Mixer |

30Liter; mixing speed:0~70rpm; dispersion speed: 0 ~ 3800 rpm |

|

Cathode material mixing |

|||

|

30L vacuum mixer(basic model) |

30Liter; mixing speed:0~70rpm; dispersion speed: 0 ~ 1400 rpm |

||

|

Coating |

Anode coating |

Slot die coating machine |

300mm width, drying oven length: 6m, coating speed: 1~5m/min, slot die coating |

|

Cathode coating |

|||

|

Small automatic coating machine |

film applicator coating, 280mm coating width |

||

|

Pressing |

Anode rolling press |

Hydraulic controlled hot rolling press |

Roller size: φ300*400mm; heating temperature: rt~120℃ |

|

Cathode rolling press |

|||

|

Hydraulic controlled rolling press |

Roller size: φ200*330mm, without heating function |

||

|

Cutting |

Anode cutting |

Automaitc die cutting machine |

Maximum material width: 360mm

Die cutting speed: 18000p/h

|

|

Cathode cutting |

|||

|

Semi-automaitc die cutting machine |

Suitable battery size: within 200*200mm |

||

|

Stacking |

Electrode stacking |

Single Work Station Automatic Stacking Machine |

about 20 cells/hour, maximum stackable size: 190mm L*150mm W |

|

Pouch Cell Automatic Layer by Layer Stacking Machine |

maximum stackable size: 200mm L*200mm W |

||

|

|

Tab welding |

Ultrasonic Metal Spot Welder |

2000W, 3600W, 4000W |

|

Case forming |

Case forming |

Automatic forming machine |

20pcs/min |

|

Semi-automatic forming machine |

Suitable battery size: within 150*150mm |

||

|

Sealing |

Edge sealing |

Top& side sealer |

Automatic, maximum sealing length: 200mm |

|

Manual, maximum sealing length: 200mm |

|||

|

Electrolyte filling&pre sealing |

Automatic Electrolyte Filling Machine |

Automatic vacuum injection, vacuum diffusion and degassing , shaping, automatic vacuum sealing; suitable cell size: 160mm L*120mm W |

|

|

Diffusion and degassing |

Diffusion & Degassing Chamber |

Air Inflation Time: 0 - 99.99 sec

Vacuum Condition Hold Time: 0 - 99.99 sec

|

|

|

Cell core press |

Hot/Cold Press Machine |

Pressure range: 0 ~ 500kg adjustable; Heating temperature: 20~150℃ |

|

|

Formation |

Hot Press Pressure Formation Machine |

5V5A 128channel |

|

|

Final sealing |

Three-Station Final Sealer |

Sealing time adjustment range: 1s-30s |

|

|

Final Sealer |

one cell one time |

||

|

Testing |

Charging and discharging |

Battery Tester For Charging And Discharging |

512 Channel 5V6A |

Online service

Online service +86 13174506016

+86 13174506016 Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8613174506016

+8613174506016