Coin Cell Lab Machine: Empowering Battery Research and Development

Introduction:

In the dynamic realm of battery research and development, the "Coin Cell Lab Machine" shines as an essential tool that empowers scientists and engineers to explore the frontiers of energy storage. This specialized equipment serves as a versatile platform for fabricating and testing coin cell batteries, enabling intricate analysis, optimization, and innovation in the field. In this article, we delve into the capabilities, components, and significance of the Coin Cell fabrication Machine in advancing battery technology.

Coin Cell Batteries: Building Blocks of Energy Storage:

Coin cell batteries are small, button-like cells commonly used for research, testing, and prototyping in the battery industry. They serve as fundamental units for evaluating the performance, characteristics, and chemistry of different battery materials and designs.

Exploring the Coin Cell Lab Machine: Components and Features:

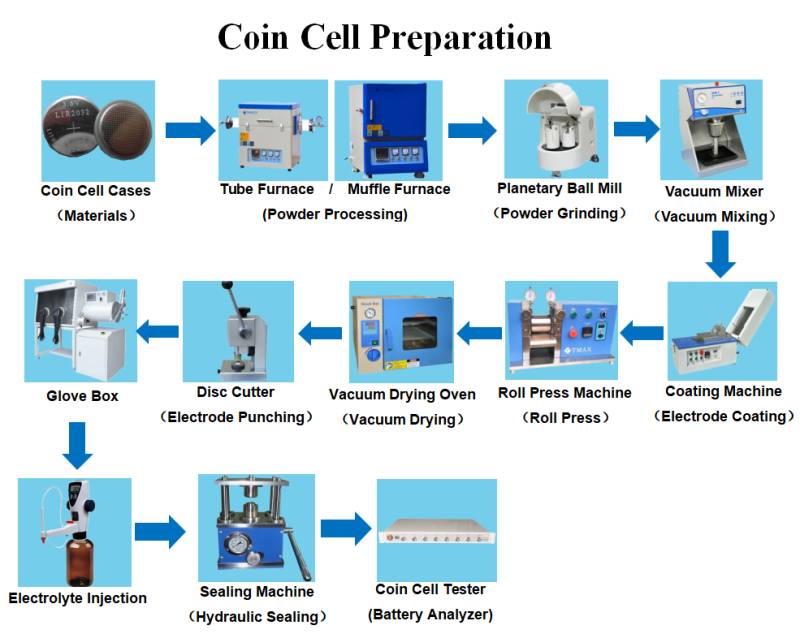

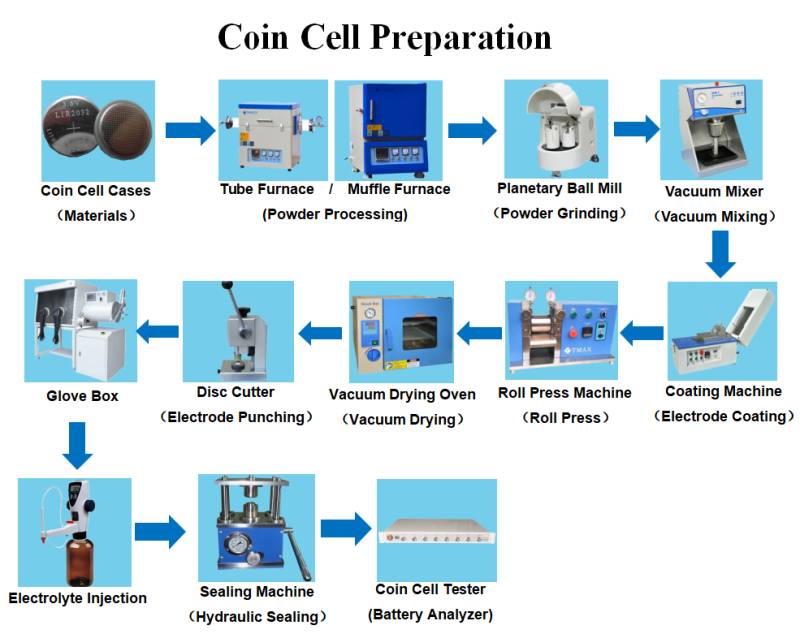

A Coin Cell Lab Machine is a multifunctional device equipped with various components to facilitate the fabrication, assembly, and testing of coin cell batteries:

Electrode Preparation: The machine often includes tools for preparing cathode and anode electrodes. This involves coating electrode materials onto current collectors, drying, and cutting them to precise dimensions.

Electrode Assembly: The lab machine enables precise stacking of cathode and anode electrodes, along with separators, to create the coin cell's internal structure.

Electrolyte Dispensing: Accurate dispensing of electrolyte is critical. The machine facilitates controlled injection of electrolyte into the coin cell, ensuring optimal ion movement.

Coin Cell Crimping or Sealing: Coin cell components are hermetically sealed together to prevent leakage and ensure the integrity of the electrolyte.

Testing Chambers: These chambers are equipped with specialized equipment for characterizing the performance of coin cell batteries. They often include functions for charge-discharge cycling, capacity testing, impedance spectroscopy, and voltage profiles.

Temperature Control: Some lab machines offer temperature control capabilities to study the impact of varying temperatures on battery performance.

Significance and Applications:

The Coin Cell pilot Machine serves as a hub for innovative battery research and development:

Material Exploration: Scientists can test various cathode, anode, and electrolyte materials to determine their suitability and compatibility for specific applications.

Electrode Design: Researchers can optimize electrode designs, thicknesses, and compositions for enhanced battery performance.

Performance Analysis: The lab machine facilitates comprehensive testing, allowing researchers to evaluate capacity, cycle life, energy density, and impedance characteristics.

Prototyping: The coin cell format enables rapid prototyping of new battery configurations, providing insights into the feasibility of novel designs.

Quality Control: Manufacturers can utilize the machine to perform quality control tests on battery materials and components before scaling up production.

Education and Training: Academic institutions use coin cell lab machines to train students in battery technology and conduct hands-on research.

Conclusion: Powering Innovation and Progress:

The Coin Cell Lab Machine stands as a cornerstone in the world of battery research and development. By offering a controlled and versatile platform for fabricating, testing, and analyzing coin cell batteries, it accelerates the pace of innovation, enabling advancements in energy storage technology. From optimizing materials to refining battery designs, this equipment fosters collaboration and exploration, propelling us towards a future powered by efficient, sustainable, and cutting-edge energy storage solutions.

Online service

Online service +86 13174506016

+86 13174506016