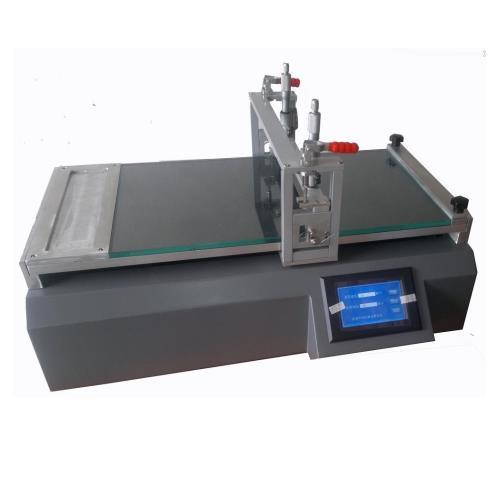

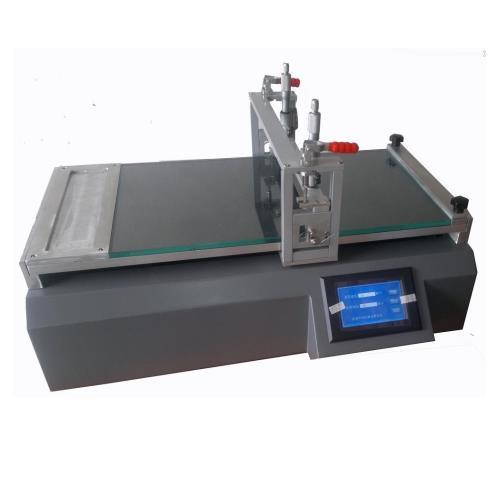

An extrusion coater is a piece of industrial equipment used in the process of coating materials by extruding a liquid or molten material onto a substrate. It’s commonly used in the packaging, printing, and textile industries to apply coatings such as adhesives, laminates, or polymer films to various materials like paper, fabric, metal, or plastic. The process involves:

1. Extruder: The machine heats and melts a material, usually a polymer like polyethylene, and forces it through a die.

2. Coating Application: The molten material is extruded through a slit die and applied to the substrate, which is typically passed under or around a coating station.

3. Chill Roll: After the material is applied, the coated substrate is passed over a cooling or chill roll to solidify the coating.

4. Rewinding: The coated substrate is then rewound into rolls for further processing or use.

●Applications:

- Flexible Packaging: Extrusion coating is used to create moisture-resistant or heat-sealable layers.

- Paper and Board Coating: The process adds a barrier to paper or cardboard for use in food packaging.

- Textile and Fabric Coating: It adds water or heat-resistant layers to fabrics.

This method provides high precision and uniform coatings, making it ideal for high-volume production environments.

Online service

Online service