Lab 150ML 300ML Vacuum Planetary Centrifugal Mixer with Double Cup

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-PCV-2KLDPayment:

L/C D/A D/P T/T Western UnionShipping port:

Xiamen PortLead Time:

5 daysHigh-speed Two Containers Vacuum Planetary Centrifugal Mixer with 3 Programmable Segments

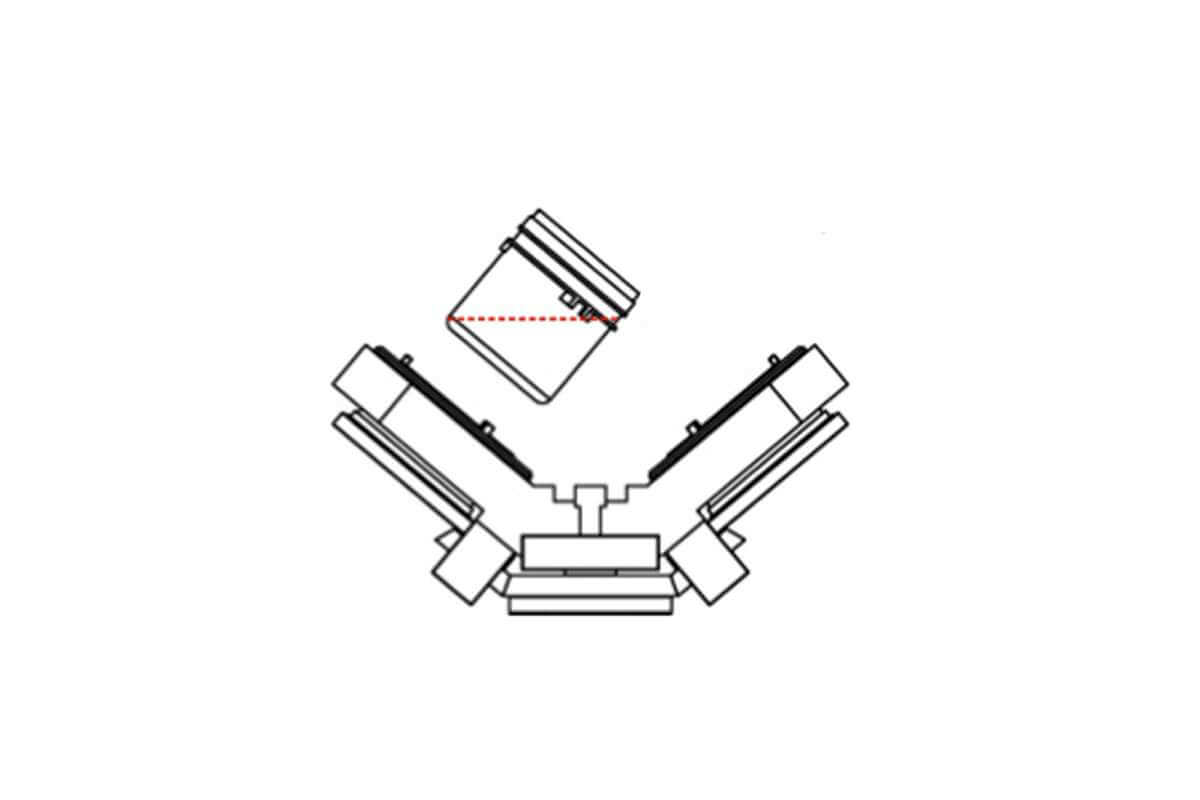

TMAX-PCV-2KLD is a high-speed mixer designed for ball milling and mixing various powder materials with two containers up to 1000 ml/each, The container can be revaluated around the main disk and rotated by self-rotating up to 2000 RPM. The container's regulating and rotating speed is controlled independently. which allows the user to adjust impact force and shearing force during milling or mixing based on different materials.

TMAX-PCV-2KLD has a built-in vacuum pump and can be operated under vacuum conditions to remove gas micron-bubbles inside the slurry.

|

Features |

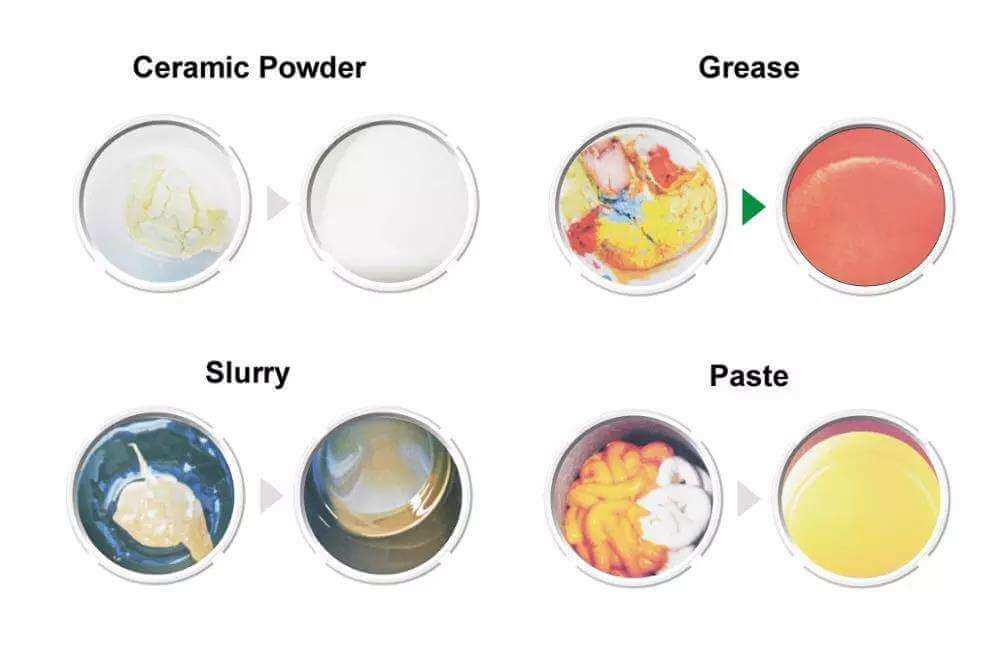

· Mixing under vacuum for deaeration upto 1 Torr · Two containers for mixing or milling sample upto 500 ml./ea ( including container’s weight ) · Minimized contamination (no metal mixing blade) · These peeds of main disk revolution and of container self-rotating are controlled independently upto 2000 RPM to provide various i mpact and shaering force. · Sample Materials · Nanopowders, ceramic powders · Grease · Slurry · Paste |

|

Voltage Input |

· Single Phase AC 208 - 240V, 50/60 Hz, three phase |

|

Power |

· Maximum: 4000 W |

|

Mixing and Speed |

· Planetary Centrifugal Vacuum Mixing · Main Platen Rotation (revolution motion):0 - 1500 RPM (adjustable) · Container Spin (rotation motion): Adjustable between Main platen Speed and 1500 RPM ( Speed can not lower than main platen speed ) · |

|

Vacuum Capability |

· The chamber is vacuum sealed with built in mechanical pump. · Pumping Rate: 165 L/min · Ultimate Vacuum: -95 kPa |

|

Containers and Counter-Weights |

· Two standard containers and counter-weights are included · Two 1000 mL containers with gas vent, made of high-density Polyethylene · For small amount of sample mixing, the adaptor for small container is available at extra cost. · For ball milling, stainless steel liner and aspirator is available upon request at extra cost.

· |

|

Program |

· Store up to 6 programs in memory, · 3 programmable segments, · Maximum running time for each segment is 200 sec. Maximum total running time is 600 sec · The rotation direction could be either clockwise (mode A) or counter-clockwise (mode B)

|

|

Safety and Protection |

· Safety warning and interlocks are integrated. The unit automatically stops when · The unit is overloaded with the sample · The sample is loaded in an unbalanced way · The top cover is opened |

|

Warranty |

· Two years limited standard warranty with lifetime technical support |

|

Dimension |

· 655 mm (W) x 950 mm (H) x 805 mm (D) |

|

Weight |

· 395 kg |

|

Application Notes |

· Always use the mixer on level & stable surface for best performance and maximum safety · Do not use the mixer in a hazardous atmosphere, or with flammable, explosive, corrosive, poisonous material! Check the chemical resistance of the container with the different material before loading the sample!!! · Do not overload the mixer! Stop the mixing operation immediately if abnormal sound/vibration are observed · Use a digital balance to make sure the sample loading is balanced before mixing · Double check if the containers are mounted correctly and securely before mixing · Do not open the cover lid until the rotation has completely stopped! Do not retrieve the containers and/or put hand close to mixing fixture while the rotation has not completely stopped! · Only use the included containers for the mixing operation! Double check to make sure there is no foreign object in the mixer before mixing |

Online service

Online service +86 13174506016

+86 13174506016 Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8613174506016

+8613174506016