Lab Vertical Programmable Square Ball Mill Optional Tanks of Different Material

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-QXQMPayment:

L/C D/A D/P T/T Western UnionShipping port:

Xiamen PortLead Time:

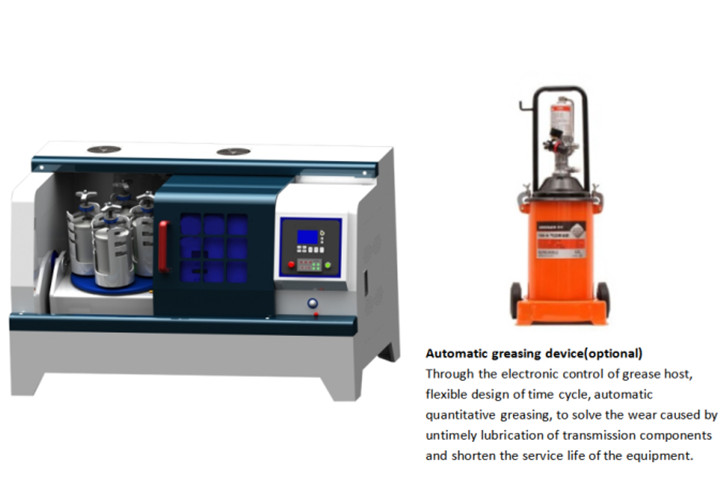

5 daysLab 360C All-round Comprehensive Planetary Ball Mill

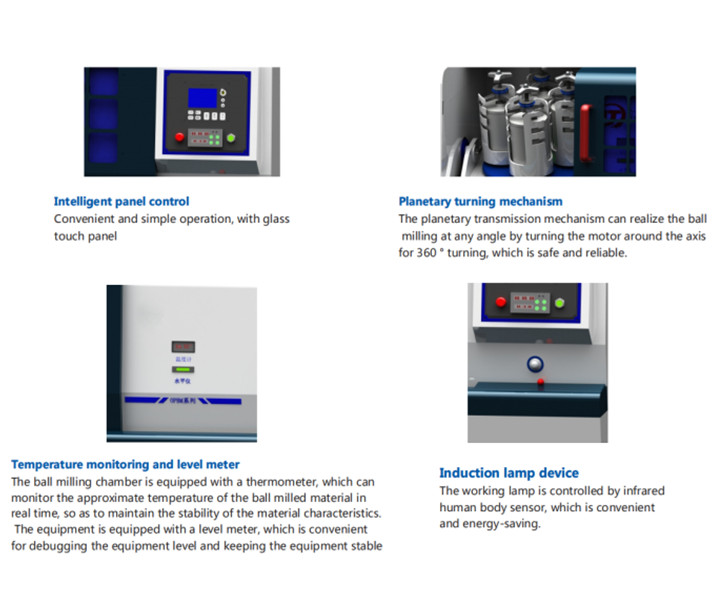

The comprehensive planetary ball mill is based on the vertical planetary mill, adding the turning function of the planetary transmission mechanism. While the planetary plate and the materials and grinding balls in the ball mill can do the planetary movement, they can also do the 360 ° turning in a fixed space, so as to realize the multi-dimensional and multi-directional movement of the grinding balls and materials in the ball mill, improve the degree of disordered movement of the grinding balls and materials, and complete There is no dead angle for grinding materials in the grinding tank, which makes the ground materials more uniform, and solves the problems of sinking and sticking of some materials.

Features

The equipment is light and easy to operate. The shell is made of high-precision laser cutting, CNC bending, elegant and high-end stable. The planetary disk and structural components are processed by CNC processing technology, and the nitriding metal heat treatment technology ensures the wear-resisting of the rotating shaft and prevents the shaft from breaking. The transmission gear is made of high-temperature wear-resistant non-metal and metal combination precision gear, lubricated by grease It can be equipped with our company's automatic greasing device, which can flexibly set how long the automatic quantitative oiling can take. It can solve the wear caused by the untimely lubrication of the transmission components, shorten the service life of the equipment, and ensure the smooth and quiet operation of the equipment at high speed.

Specifications

|

Transmission mode |

Gear drive |

||||||

|

Maximum sample loading |

2/3 of the capacity of the ball mill |

||||||

|

Volume of ball mill |

0.05L-10L per tank, total volume 0.2l-40l |

||||||

|

Feed size |

Soil material≤10mm, other materials≤3mm |

||||||

|

Discharge particle size |

Up to 0.1um minimum |

||||||

|

Speed regulation mode |

Stepless speed regulation of frequency converter |

||||||

|

Model |

Volume (L) |

Applicable jar volume |

Power(kW) |

Runing time(min) |

Revolution speed(rpm) |

Rotation speed(rpm) |

Weight(kg) |

|

OPBM-0.4 |

0.4 |

50-100ml |

0.25 |

1-9999 |

47-465 |

94-930 |

140 |

|

OPBM-1 |

1 |

50-250ml |

0.75 |

1-9999 |

35-370 |

70-740 |

280 |

|

OPBM-2 |

2 |

50-500ml |

0.75 |

1-9999 |

35-370 |

70-740 |

280 |

|

OPBM-4 |

4 |

250-1000ml |

0.75 |

1-9999 |

35-370 |

70-740 |

285 |

|

OPBM-6 |

6 |

1-1.5L |

0.75 |

1-9999 |

35-370 |

70-740 |

290 |

|

OPBM-8 |

8 |

1-2L |

1.5 |

1-9999 |

35-320 |

70-640 |

345 |

|

OPBM-10 |

10 |

1-2.5L |

1.5 |

1-9999 |

35-320 |

70-640 |

345 |

|

OPBM-12 |

12 |

1-3L |

1.5 |

1-9999 |

35-320 |

70-640 |

350 |

|

OPBM-16 |

16 |

2-4L |

3 |

1-9999 |

30-255 |

60-510 |

400 |

|

OPBM-20 |

20 |

2-5L |

4 |

1-9999 |

25-215 |

50-430 |

710 |

|

OPBM-40 |

40 |

5-10L |

5.5 |

1-9999 |

20-195 |

40-390 |

1000 |

Model selection guidance

Selection of size of planetary ball mill:

According to the number of materials to be ground, choose the size of the planetary mill.

Calculation formula for size selection of planetary ball mill: a = C /ρ* 3.

Note: A is the size of planetary mill (unit: l), C is the mass of primary grinding material (unit: kg), ρis the bulk density of grinding material (unit: kg /L).

For example, if 2kg of material is ground at one time and the bulk density of material is 1.5kg/L, the size of planetary mill in row a = 2/ 1.5*3 = 4L is selected.

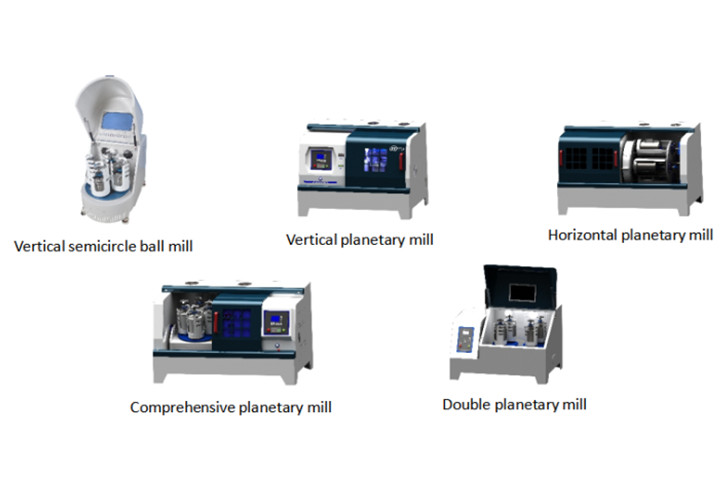

Planetary ball mill style and special function configuration options:

Planetary ball mill is divided into vertical, horizontal, comprehensive, double planet four styles, according to the material grinding requirements, choose the corresponding styles, each style of products can be equipped with air cooling or heating equipment according to the grinding material temperature requirements.

Reference table for selection of planetary ball mill style and special function configuration

|

Model selection of planetary ball mill |

Nature of abrasive material |

|

Vertical planetary mill |

Grinding of general materials, no special requirements |

|

Comprehensive planetary mill or horizontal planetary mill |

The material is easy to sink and bind |

|

Double planetary mill |

Ultra high speed and ultra-fine grinding are required |

|

With air cooling device or liquid nitrogen device |

The grinding process is hot and needs to be cooled |

|

Equipped with vacuum ball milling tank |

Easy to oxidize, requiring vacuum environment or atmosphere protection |

|

With heating device |

High temperature grinding required |

Online service

Online service +86 13174506016

+86 13174506016 Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8613174506016

+8613174506016