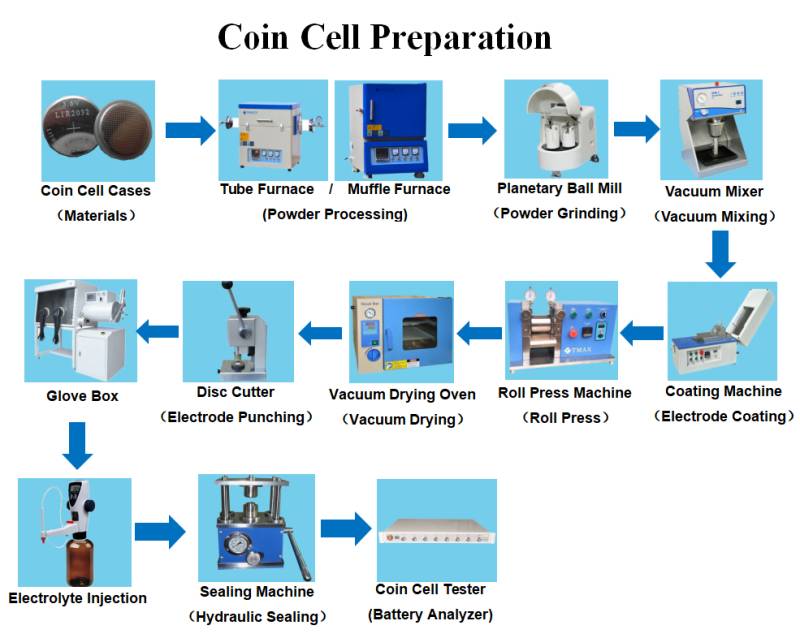

CR2032/2025/2016 Coin Cell Assembly Machine Plant For Lab Scale Lithium-ion Battery Research

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-PCSPayment:

Credit Card, Paypal, T/T , Western Union, LCLead Time:

5 daysLaboratory CR20XX Coin Cell Pneumatic Crimper Machine For Lithium Battery Making

Introduction

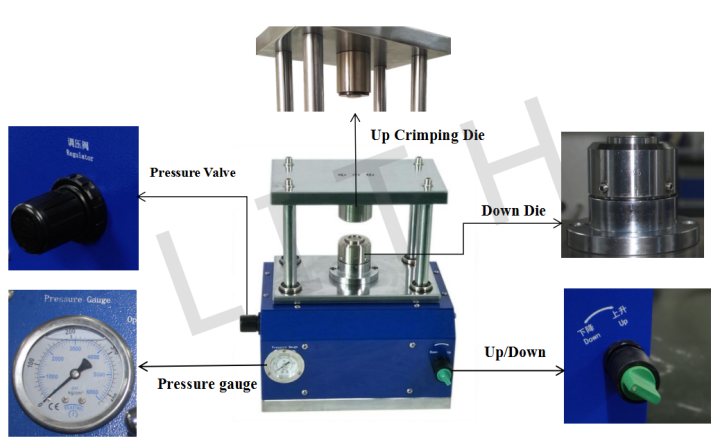

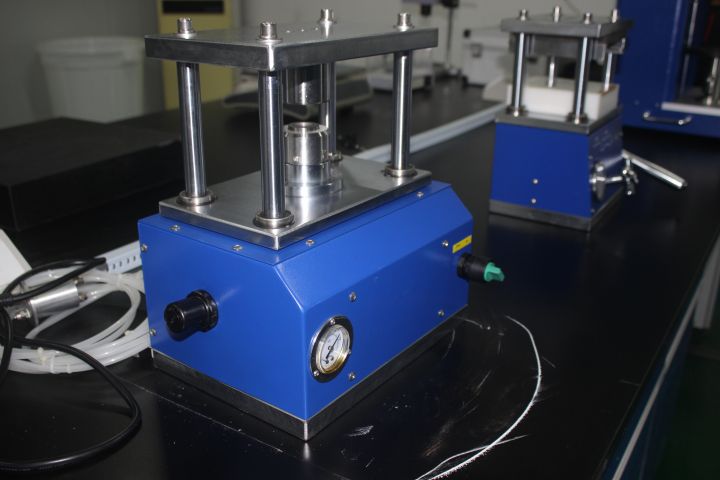

LITH-PCS coin cell crimper is a newly designed coin-cell sealing machine with lighter weight. It’s mainly used for coin cell battery material lab researching, Capacitor sealing research, also be used in small batch trial production in factories.equipped with different die,also used for disassemble battery, press electrode sheet,press battery powder,etc.

2. In addition, customers can easily replace the original die for disassembling purpose.

3. It can also be worked in glove box with smaller volume.

Main features

*The lower mold is limited by a high-precision positioning ring to control the battery packaging height, so as not to cause excessive and unstable packaging pressure, which may cause damage to the battery and the sealing cup.

*The inner ring of the upper mold sealing cup is equipped with a screw spring centering mechanism to ensure that in case the battery is stuck and cannot be removed during sealing, the button battery can be forced out by twisting the top screw.

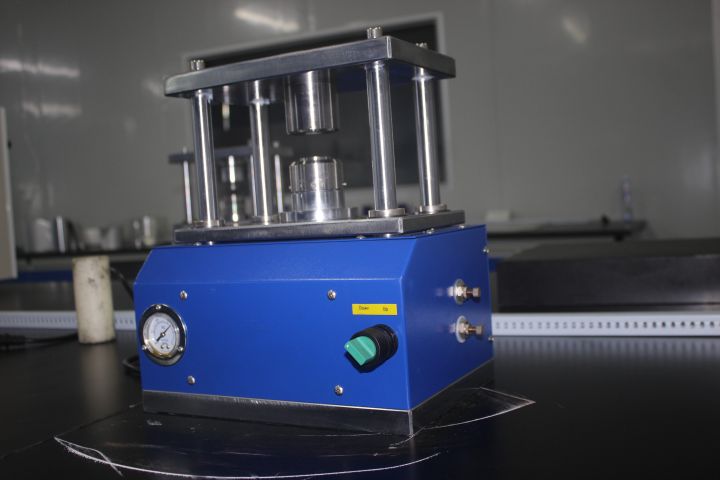

*Compressed air or inert gas cylinders are used to supply air, and the compressed air exhaust can be connected to prevent damage to the glove box atmosphere.

*Precision mold design ensures accurate and reliable sealing forming, solid steel structure design, stable and safe use.

*Pure pneumatic operation, no electricity, convenient and easy to use;

Instructions

1. Battery placement: In the mold open state, put the battery into the positioning groove of the lower mold with the negative side facing up, and place it straight and smooth.

2. Battery sealing: Twist the mechanical valve to open, switch the gas path to make the movable template rise and pressurize to close the mold, that is, to realize the battery encapsulation.

3. Take out the battery: Twist the mechanical valve to close, switch the gas path to lower the movable template, and the sealing mold will automatically open. After the mold is opened, you can take out the battery.

4. Battery sealing height limit adjustment: Loosen the 4-machine meter screw on the side of the sealing limit nut, and turn the nut to adjust the height to limit the battery sealing height. After adjustment, tighten the side machine meter screw.

Technical parameters

|

Air source |

0.7~0.8MPa argon, nitrogen gas cylinder, or compressed air (compressed air is not recommended in the glove box) |

|

Exhaust design |

specially designed exhaust port, which can be connected externally through KF40 and other devices |

|

Air consumption |

about 480ml of air consumption for a single seal |

|

Sealing pressure |

manual control valve control, recommended pressure 0.7MPa |

|

Sealing stroke |

30mm |

|

Sealing mold |

standard CR20 series packaging mold, optional or additional specifications |

|

Unpacking mold |

CR16, CR20, CR24, CR30 and other specifications can be selected or added |

|

Dimensions |

L290mm*W205mm*H330mm |

|

Weight |

25kg |

|

Function |

It has the function of preventing short circuit of battery sealing. |

|

Structural material |

high-strength chromium steel, the surface will never rust after environmentally friendly electroplating and spraying treatment. |

Online service

Online service +86 13174506016

+86 13174506016 Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8613174506016

+8613174506016