Large Dual-Filtration System NMP Vapor Recovery System Machine of Lithium Battery Coating

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-YK-NMP-50000Payment:

Credit Card, Paypal, T/T , Western Union, LCLead Time:

5 daysLowest Power NMP Recovery System For Prismatic Cell Electrodes Production

Chapter I Equipment Introduction

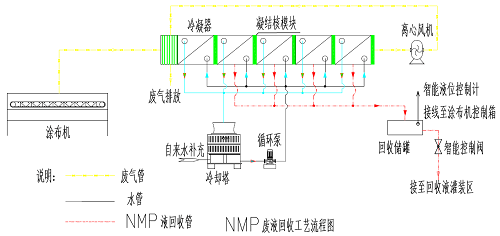

1、NMP Working principle of recovery system

NMP recovery system uses the physical characteristics of NMP and adopts multi-stage condensation to fully condense and realize recovery. The temperature of the waste gas discharged from the coater is about 120 ℃. The temperature can be reduced to about 25 ℃ through the recovery system, which can cool and recover more than 95% of NMP.

2、System characteristics

2.1、The effect is good, and the solvent recovery can reach more than 95%; The purity of recovered NMP waste liquid reaches more than 80%;

2.2、Energy saving. The energy consumption of the system itself is only 4.0kw/h (taking 50000m3/h air volume and air duct length less than 20m as an example). So far, it is the equipment with the lowest power consumption in all NMP recovery systems, and the product is recommended by the national environmental protection department;

2.3、Long term stability: the NMP recovery system produced by our company can ensure that its performance (recovery rate, recovery concentration) will not be reduced within 3 years, and its stability will reach the best state;

2.4、The safety performance is good. The equipment has special fault handling settings. Even if there is a sudden fault, there will be no backflow, suffocation and other accidents that affect the normal operation of the coater.

3、Technical requirement

Item

Unit

Specification

1)Exhaust air volume

m3/h

50000(Exhaust air volume of coater)

2)Air outlet temperature

℃

120℃

3) NMP consumption

kg/h

Above 45

2、NMP Technical requirements for recycling

1)rate of recovery

≥95%

2) Recovery concentration

≥80%

3) NMP exhaust emission concentration after recovery

PPM

Below 200

3、Material of auxiliary facilities

1)Ventilation duct

White iron pipe

300mmx300mmx0.0.6mm

4、Process performance requirements

SN

Item

Specification

1

Energy saving performance

Use tube fin heat exchanger to save energy consumption.

2

Sealing performance

All connections in the unit are sealed with high-temperature silica gel and high-temperature glue. The air leakage rate at the connection of each functional section is less than 0.5%.

3

Linkage performance

Linked with the coater separately, the unit can operate under the best working conditions, and the recovered NMP concentration is more stable.

4

Others

After the equipment stops running, NMP cannot flow back to the air inlet pipe, and when the NMP recovery system fails, it will not affect the use of the coater.

Chapter II System Design

1、Design parameters

Exhaust temperature:120℃

Treatment air volume:50000m3/h

Rate of recovery:≥95%

Concentration of recovered waste liquid:≥ 80%

Exhaust emission concentration:Below 200 ppm

2、Technological process

The process flow chart is as follows:

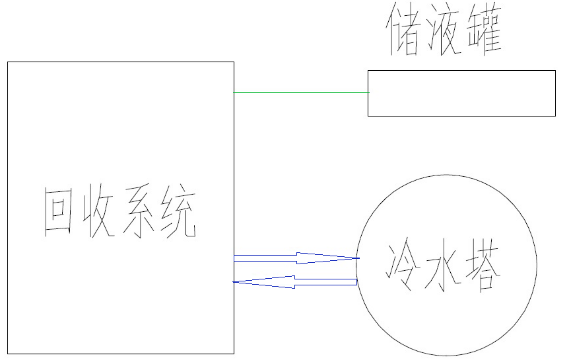

3.4、Layout plan of recycling system

3.5、Recovery process pipeline diagram

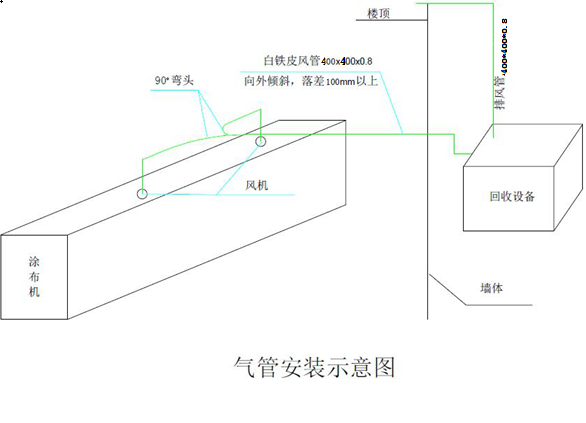

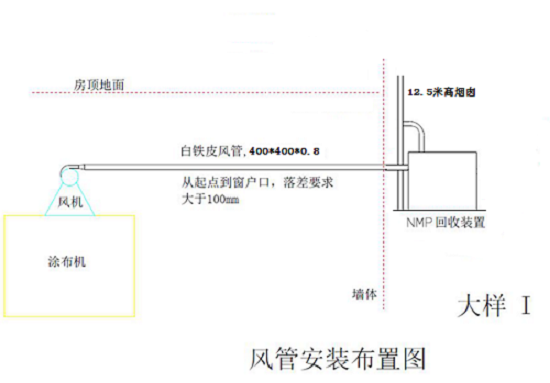

3.6、 Air duct installation layout diagram

4、Main equipment of the system

|

SN |

Organization name |

Part name |

Material |

Specification |

Manufacturer |

|

1 |

Cooling solvent recovery section

(condenser) |

Cooling coil 1 |

Aluminum wing & copper tube |

XYZ-500-6 |

TMAX |

|

2 |

Cooling coil 2 |

Aluminum wing & copper tube |

XYZ-500-8 |

TMAX |

|

|

3 |

|

|

|

TMAX |

|

|

4 |

|

|

|

TMAX |

|

|

5 |

Liquid blocking plate |

Corrosion resistant stainless steel |

|

TMAX |

|

|

6 |

Effusion disk |

Corrosion resistant stainless steel |

|

TMAX |

|

|

7 |

Recovery tank |

Corrosion resistant stainless steel |

|

TMAX |

|

|

8 |

Liquid level pump |

Anticorrosive materials |

|

Xiaoyezi |

|

|

9 |

Forced draft fan section |

Manual air valve |

Anticorrosive materials |

|

Xiaoyezi |

|

10 |

Centrifugal fan |

Anticorrosive materials |

7KW |

Xinfeng |

|

|

11 |

Water cooling circulation section |

cooling tower |

|

20T |

Liangyuan |

|

12 |

water circulating pump |

|

2P |

Chinese Trumpet Vine |

|

|

13 |

|

|

|

|

|

5、Electrical design

5.1 electrical part (function and implementation mode)

6. Product Images:

Online service

Online service +86 13174506016

+86 13174506016 Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8613174506016

+8613174506016