Roll Grooving Machine For Cylinder Supercapacitor

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-XCJ-3270CPayment:

Credit Card, Paypal, T/T , Western Union, LCShipping port:

Xiamen PortLead Time:

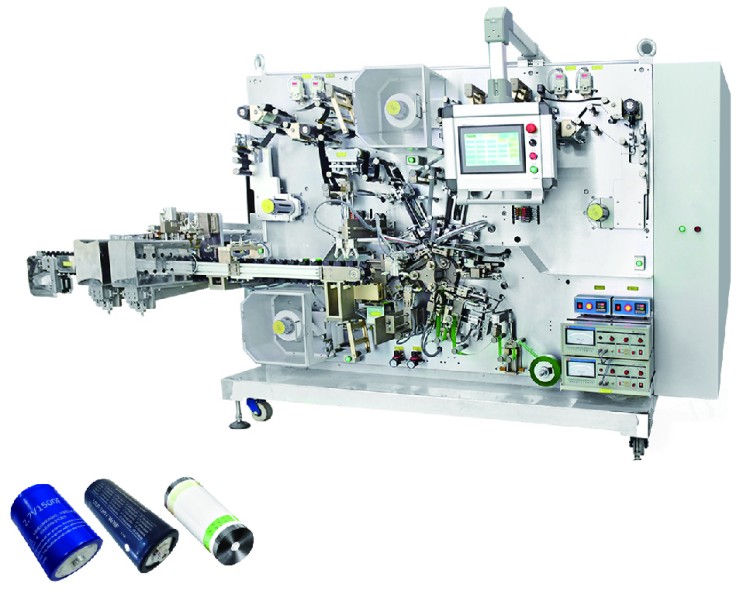

5 daysSuper Capacitor Winding Machine for Supercapacitor Core Making

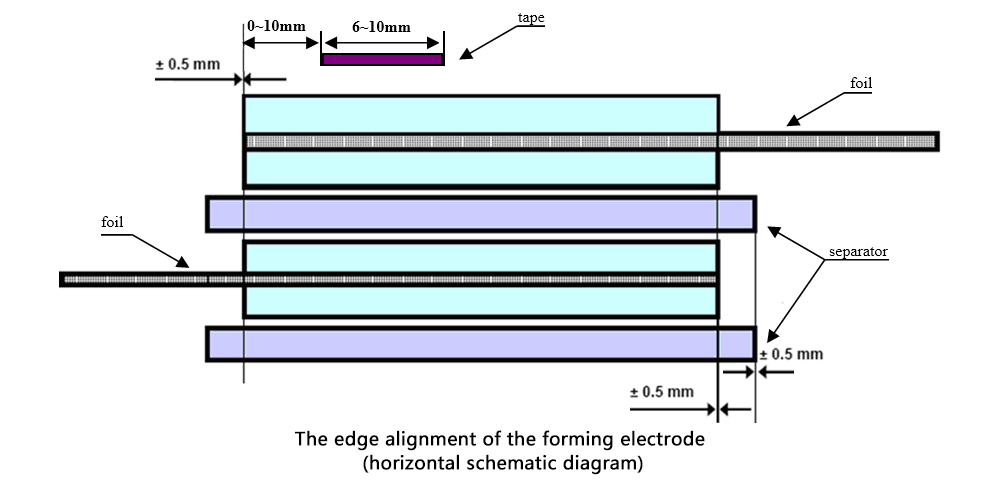

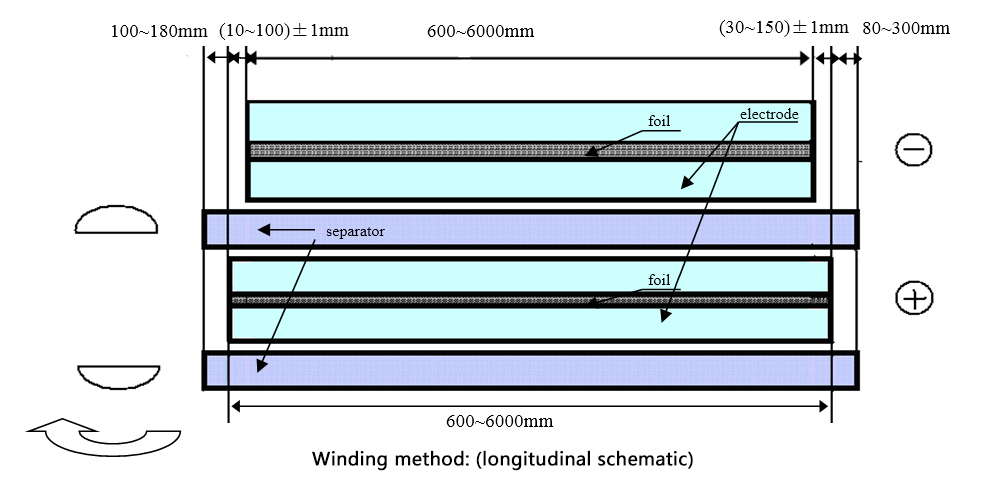

This cylindrical battery cells automatic winding machine is equipped with manual feeding with cathode and anode electrode sheet, separator, and tapes. After completion the feeding, the cathode and anode electrode sheet, separator, tapes which used after winding, and protective tapes (protect the cell) are automatic winding according to predetermined product and process requirements. Detection, automatic tension control, automatic deviation correction, short circuit test and other functions. The equipment has a stable and reliable working state and process guarantee.

Process flow:

1. Separator feeding

2. Tape (tape which used after winding) and tape (protect the cell) feeding

3. Cathode and anode electrode feeding

4. Cathode and anode foil detection

5. Electrode (whole roll electrode) winding

6. Length and diameter control

7. Paste tape (tape which used after winding) and protective tape (protect the battery cell)

8. Short circuit test

9. Judgment of quality products

|

Material |

Feeding method |

Single pieces material length(mm) |

Material Width(mm) |

Material thickness(μm) |

Maximum outer diameter(mm) |

Inside diameter(mm) |

||

|

Size range |

Size range |

Tolerance |

Size range |

Tolerance |

||||

|

Cathode electrode |

Coil material |

1000~6000 |

80-160 |

±0.1 |

100~320 |

±10 |

400 |

75.8 |

|

Anode electrode |

Coil material |

1000~6000 |

80-160 |

±0.1 |

100~320 |

±10 |

400 |

75.8 |

|

Separator |

Coil material |

80-160 |

±0.1 |

16~50 |

±4 |

350 |

75.8 |

|

Equipment working conditions:

1. Power supply: AC380V±10% /50Hz, 10KW, voltage fluctuation range: ±10%;

2. Compressed air:0.45-0.6Mpa; 100L/Min

3. Environment temperature:20-35℃;

4. Relative humidity:30-55%HR;

5. No corrosive gas, liquid, explosive gas on site,

6. Equipment dimensions and weight: 2500L X 1400W X 2000H (mm); Weight: 3000 Kg

Online service

Online service +86 13174506016

+86 13174506016 Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8613174506016

+8613174506016