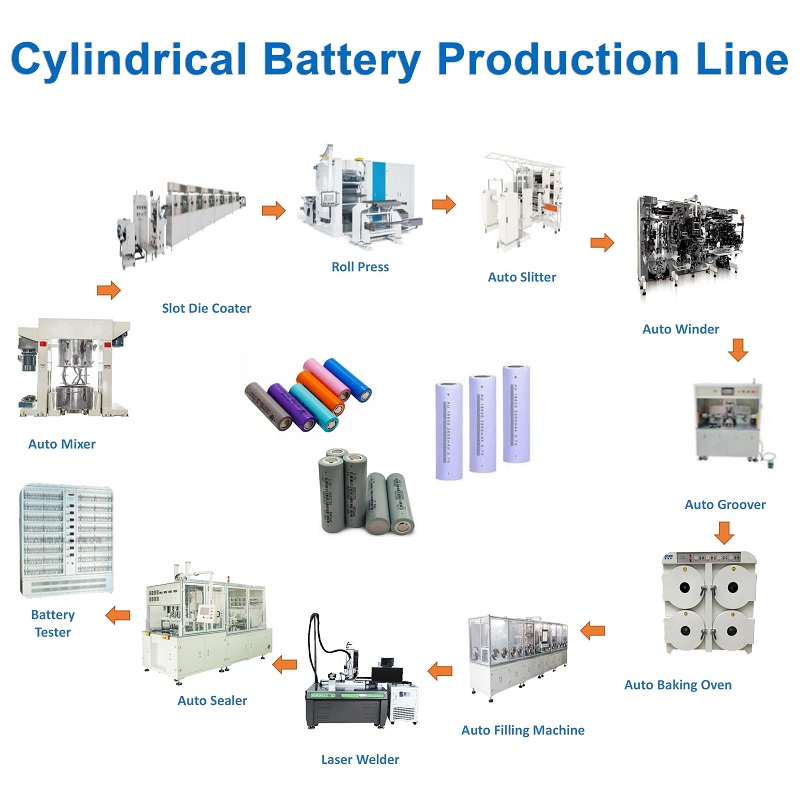

Automatic 18650/21700/26650/32650/32700 Cylindrical Cell Production Equipment Plant For Li-ion Battery Fabrication

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-BSW07-10TPayment:

Credit Card, Paypal, T/T , Western Union, LCShipping port:

Xiamen PortLead Time:

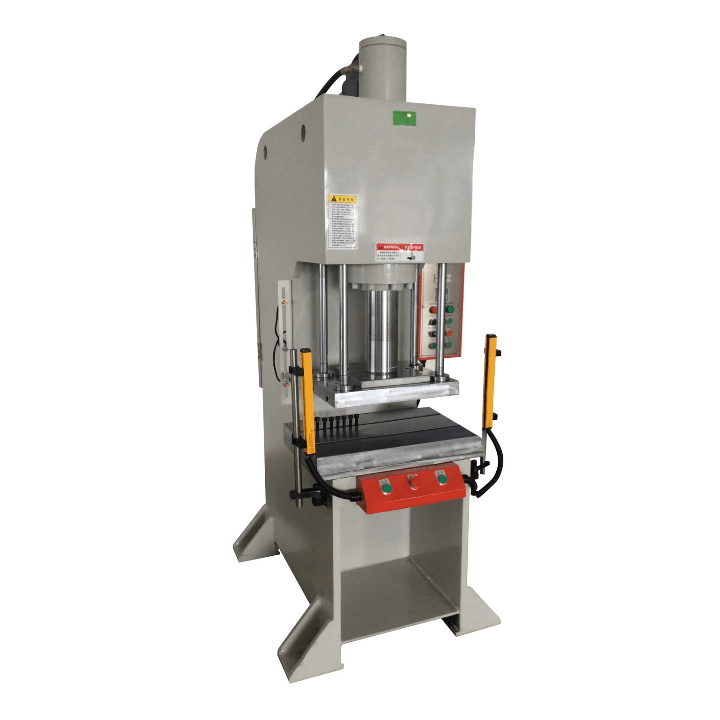

5 days10T-20T Manual Operation C-Type Single Column Servo Oil Hydraulic Press Machine

Introduction

The single-column hydraulic machine body is a C-type floor-standing structure, open on three sides, easy to operate, and tempered after welding to ensure that the frame will never deform. It is mainly used for press fitting, assembly, shallow drawing of metal products, and forming pressing. , embossing, is a general-purpose equipment for motors, shafts, auto parts, electronic hardware products, internal combustion engines, textile machinery, washing machines, electrical appliances and other factories.

Product parameters

|

Model |

BSW07 -10T |

BSW07 -20T |

BSW07 -30T |

BSW07 -40T |

BSW07 -50T |

BSW07 -60T |

|

|

Nominal pressure(T) |

10 |

20 |

30 |

40 |

50 |

60 |

|

|

Maximum working pressure of liquid(Mpa) |

21 |

21 |

21 |

21 |

21 |

21 |

|

|

Surface height (E) mm |

850 |

850 |

850 |

850 |

850 |

850 |

|

|

Maximum opening distance(H)mm |

400 |

400 |

500 |

550 |

550 |

600 |

|

|

Deep throat (s) mm |

200 |

200 |

225 |

225 |

250 |

250 |

|

|

Maximum stroke(mm) |

300 |

300 |

300 |

300 |

300 |

400 |

|

|

Work bench size

|

Left and right (L) mm |

500 |

500 |

550 |

550 |

650 |

650 |

|

Before and after (W) mm |

400 |

400 |

450 |

450 |

500 |

500 |

|

|

Speed |

Rated load speed (mm/s) |

165 |

165 |

165 |

165 |

155 |

155 |

|

Working speed(mm/s) |

24 |

24 |

24 |

18 |

15 |

15 |

|

|

Return speed(mm/s) |

140 |

140 |

140 |

125 |

125 |

125 |

|

|

Main frame size(mm) |

700x950x2050 |

700x950x2060 |

760x950x2100 |

780x950x2150 |

800x950x2150 |

830x1000x2350 |

|

|

Power(Kw) |

2.2Kw |

3.7 Kw |

3.7Kw |

3.7 Kw |

5.5 Kw |

||

Features

1. Adopting four-column and three-plate structure, the vertical precision of the movable plate is controlled by four precision guide sleeves, and the parallel precision between the lower working surface and the upper working surface is less than 0.1MM.

2. This series of hydraulic presses use 2-20MPA liquid pressure as the power source, external three-phase AC380V 50HZ or two-phase AC220 60HZ AC power supply.

3. This series of equipment uses liquid as the medium to transfer energy, high efficiency, fast cutting speed, low noise, noise of equipment does not exceed 75 decibels when standby.

4. The punching machine has a waste blowing assembly and a waste blanking trough in the center of the lower workbench (generally suitable for cutting in the die casting industry).

5. With automatic counting function, it can be divided into manual and semi-automatic control modes. Manually, the press-fit upper mold can be stopped in any stroke range. It is equipped with an emergency rebound button, and can also be equipped with an infrared hand guard device.

6. Pressure, stroke, cutting speed, blowing time, closing height can be adjusted by the customer to facilitate operation;

7. The hydraulic system has a built-in bottom of the fuel tank, and the appearance is neat and stable. The caster and the foot cup are installed under the workbench, which can be moved lightly.

8. The hydraulic mechanical output range of this series is 10tf-100tf. Optional. (1tf=1000kgf=9.8KN).

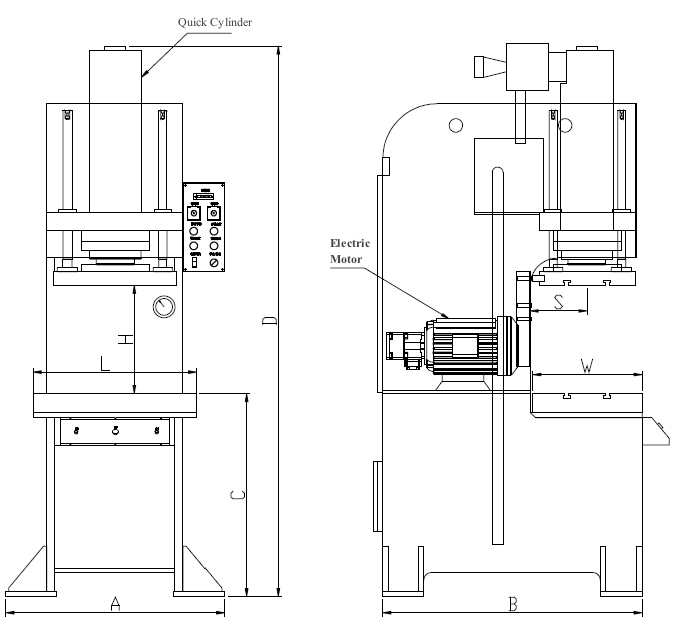

Dimension

Application

Online service

Online service Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8618659217588

+8618659217588