Laboratory 18650 21700 26650 32700 Cylindrical Cell Making Machine Plant For Lithium-ion Battery Assembly Research

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-VS-40APayment:

Credit Card, Paypal, T/T , Western Union, LCShipping port:

Xiamen PortLead Time:

5 days2000W 40KHz Ultrasonic Metal Spot Welder for Cylindrical Battery Tab and Cap Welding

Features

Ultrasonic Spot Welding Machine is a CE Certified ultrasonic metal welder with touch-screen controller. It is designed for welding stacked electrode foils/sheets and tabs onto current collectors to prepare Li-ion pouch cells & cylindrical cells.

The 2000w battery welder can weld stacked electrode with 10-35 layers aluminum foil or copper foil with Al tab and Nickel tab. If with bigger battery with layer up to 50 layers, can choose the 3000W model, and If need to weldup to 60 layers, please choose 4500W model.

Note:If you are not quite clear about what welder would be suitable for you,please consult the sales manager with following parameters,they will find a solution for you:

1. Weld material

2. Thickness of the material

3. Layer number of material

Technology Parameters

|

Features |

Preset welding programs selectable for Al and Cu (Note: Welding power can be readjusted to fit the needs for welding other types of metals such as Au, Fe, Ni, Ag...). |

|

Input Voltage |

AC 110V or 220V +/-10%, 50/60Hz |

|

Max. Power Consumption |

2200W→can be customized |

|

Welding Area |

4mm(L) x 4mm(W)→can be customized |

|

Welding Head |

The welding heads and welding base are included for welding both aluminum & copper current collectors from 2 to 40 layers |

|

Ultrasonic Frequency |

40K Hz→can be customized |

|

Product Dimensions |

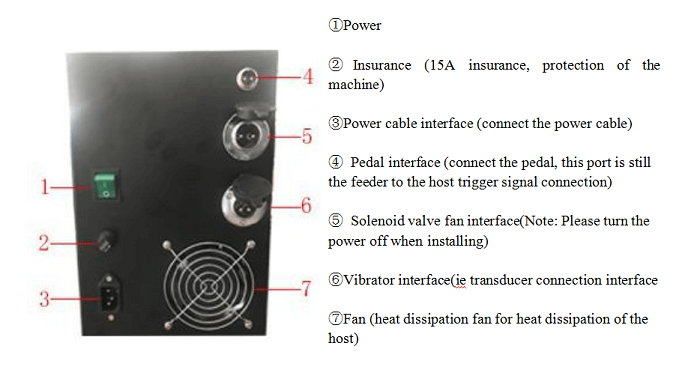

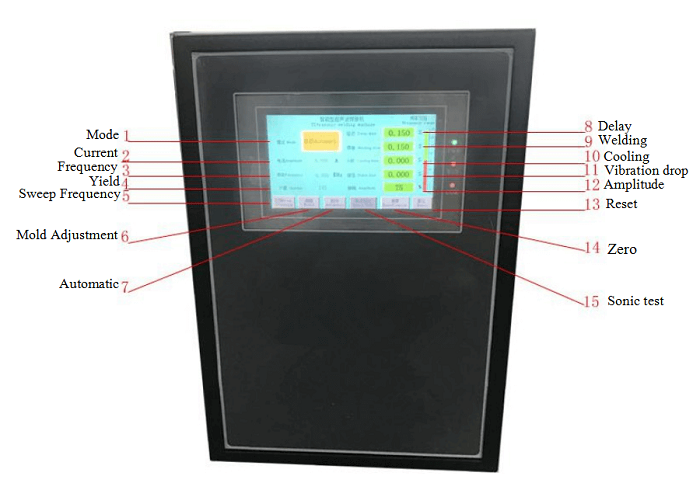

1. Controller: 360mm(L) x 480mm(W) x 200mm(H) 2. Welder: 200mm(L) x 460mm(W) x 270mm(H) |

|

Net Weight |

70kg |

|

Compliance |

CE Certificate |

|

Warranty |

One Year limited warranty with lifetime support |

|

Application Notes |

Nickel and Aluminum Tabs can be welded onto different types current collecting substrates (Aluminum or Copper) when making battery electrodes. Copper: about 0.15~2+0.15~2mm Aluminum: about 0.2~3+0.2~3mm Nickel: about 0.1~1.2+0.1~1.2mm |

| Recommendation |

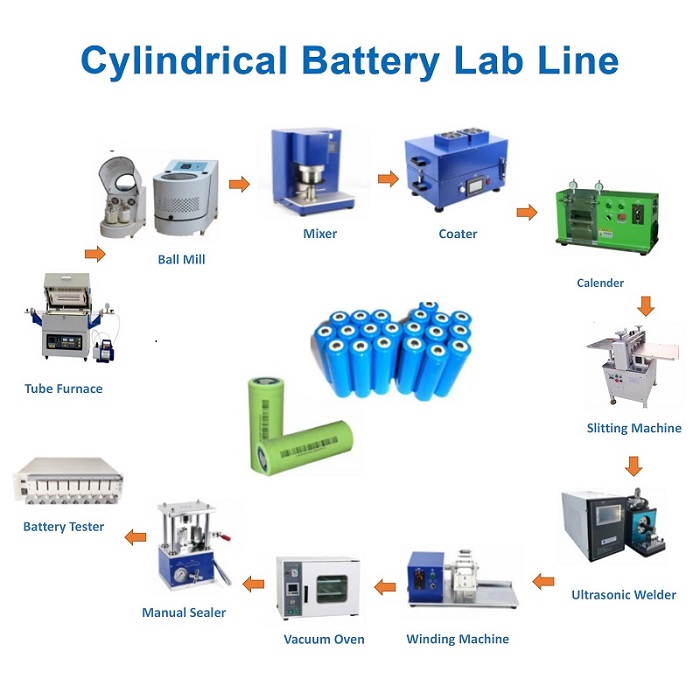

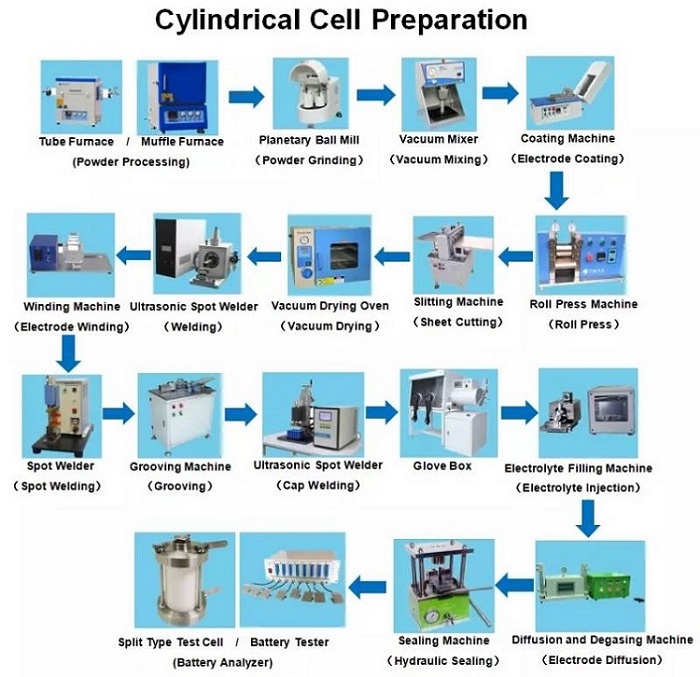

For the Cylindrical cell assembly, we also recommend you the following items:

Slitting Machine Ultrasonic Spot Welding Machine Grooving Machine sealer

Sealing Machine Battery Tester |

Online service

Online service Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8618659217588

+8618659217588