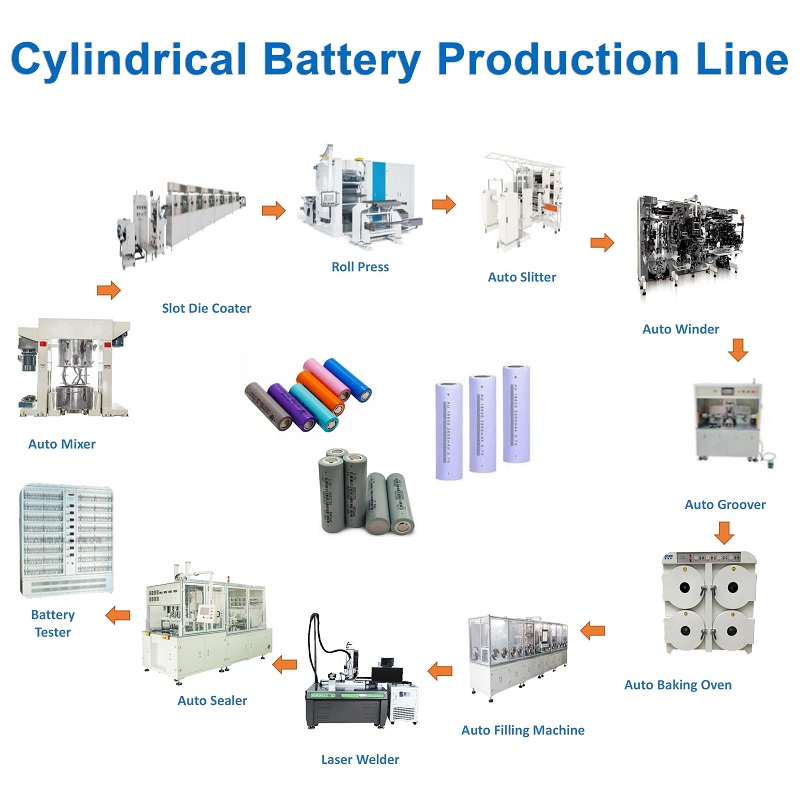

Automatic 18650/21700/26650/32650/32700 Cylindrical Cell Production Equipment Plant For Li-ion Battery Fabrication

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-WS-HJ-1000Payment:

Credit Card, Paypal, T/T , Western Union, LCShipping port:

Xiamen PortLead Time:

5 daysAutomatic Laser Welding Machine for Cylindrical Battery Cap Welding and Square Battery Shell Cover Welding

1.Equipment Introduction

It is a special model designed and developed for the welding of lithium-ion batteries (communication power battery, power storage, etc.). After equipped with appropriate fixtures, the series system can complete laser welding of square battery shell cover (four straight edges and four arc angles at the joint of shell and cover plate).

2. Workflow

Manual Feeding → Cylinder Pressing → Press the Start Button and Wait for Welding → Cylinder Loosening after Welding → Manual Feeding and Cyclic Operation.

3.Technical Parameter

|

NO. |

Project |

Parameter |

|

1 |

Central Wavelength |

1077~1085nm |

|

2 |

Full Height Half Width Spectral Width |

<3nm |

|

3 |

Rated Maximum Output Power |

1000W |

|

4 |

Power Regulation Range |

10~100% |

|

5 |

Power Stability (> 24 hours) |

<0.4% |

|

6 |

Beam Quality |

<1.2 |

|

7 |

Input Voltage |

220VAC |

|

8 |

Maximum Power Consumption |

3.5KW |

|

9 |

Maximum Modulation Frequency Max |

50KHz |

|

10 |

Waveform Rise / Fall Time |

5us |

|

11 |

Cooling Mode |

Water-Cooling |

|

12 |

Length of Output Optical Cable |

15m |

|

13 |

Laser Output Head |

QBH |

|

14 |

Operating Ambient Temperature |

5~40℃ |

|

15 |

Cooling Water Temperature |

18~28℃ |

|

16 |

Storage Temperature |

-20~60℃ |

4. Process Performance

1. Real time processing of feedback control performance and waveform control function to achieve ideal welding conditions;

2. The combination design of galvanometer scanning head can realize spot welding and seam welding within the processing range;

3. Gradual in and gradual out function, and the overlapping parts at the beginning and end of seam welding are completed;

4. The setting of input and output connectors (signals) makes automation easier;

5. Standardized workbench design, simple and flexible welding fixture debugging;

6. The battery model has strong compatibility and is equipped with universal welding fixture;

7. PC control is easy to operate, with track teaching function and easy to use

8. It is equipped with three axes as standard, which can be expanded into four axes linkage to realize arbitrary three-dimensional welding in space;

9. Touch screen man-machine dialogue interface, humanized operation, simple and intuitive.

5.Brands of Main Components

|

NO. |

Name |

Brand |

Major Function |

Quantity |

|

1 |

Laser Source |

Chuangxin 1000W connecting optical fiber laser host |

Electro optic energy conversion core |

1set |

|

2 |

Energy Transmission System |

Mitsubishi 5m optical fiber |

Energy transmission |

1set |

|

3 |

Welding Working Head |

Jiaqiang QBH welded joint |

Energy release and control of weld spot size |

1set |

|

4 |

Red Light Indication System |

Self production |

Instruction programming |

1set |

|

5 |

Welding Inspection System |

Self production |

CCD real-time detection of welding effect |

1set |

|

6 |

Energy Detection System |

Self production |

Detect energy fluctuations |

1set |

|

7 |

Cooling System |

Boding 3P double temperature and double control chiller |

Cooling cycle |

1set |

|

8 |

Workbench |

Standard four axis table |

Motion control |

1set |

6.Installation Environment Requirements

1. Configured Power Supply: AC380V, 50Hz,

Voltage Fluctuation Range: + 10% ~ - 10%;

2. Compressed Air: 0.2 ~ 0.8MPa, pressure fluctuation ± 1%

(clean air after water removal, oil-free, filtration and pressure stabilization);

3. Equipment Specification:

1) Equipment Weight: About 1000kg;

2) Overall Dimension: About L (1.5mm) * W (1.2mm) * H (1.6mm);

3) Appearance Color: Light gray.

4. Environmental Requirements:

1) Ambient Temperature: 25 ± 5 ℃;

2) Relative Humidity: 30% ~ 75% RCH, ensure that the on-site air is dry and unblocked without acid-base corrosion;

3) Ground Wire: Protective grounding;

4) Problems caused by disasters, war, abnormal weather or other force majeure.

Online service

Online service +86 13174506016

+86 13174506016 Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8613174506016

+8613174506016