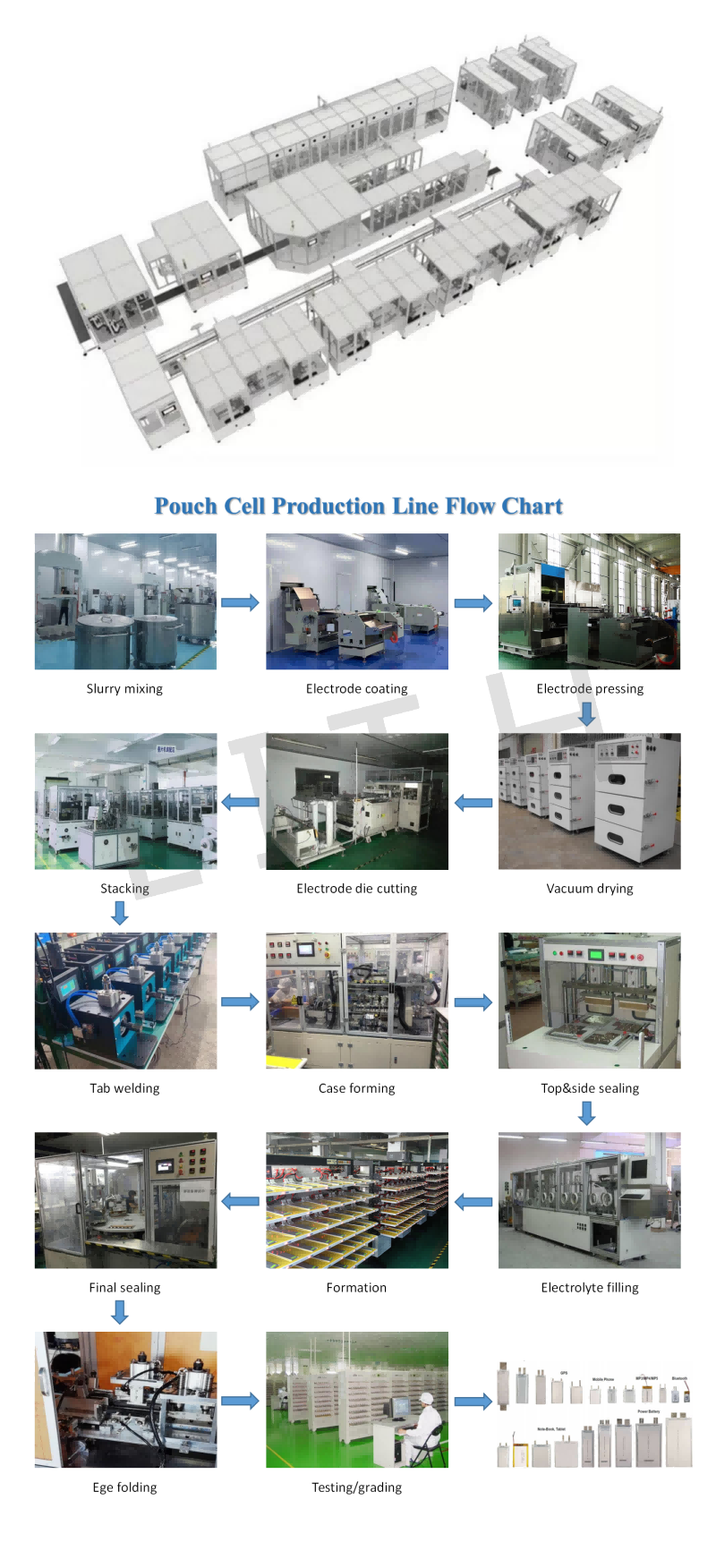

Automatic Pouch Cell Production Equipment Plant For Li-ion Battery Fabrication

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-JK-ZYJ-02Payment:

Credit Card, Paypal, T/T , Western Union, LCShipping port:

Xiamen PortLead Time:

5 daysAutomatic Pouch Cell Liquid Injection Filler Machine For Battery Electrode Filling

Introduction

It is mainly used for manual feeding and discharging, automatic vacuum injection, vacuum diffusion , degassing , shaping, automatic vacuum sealing and other functions of pouch cell lithium ion batteries.

|

Sequence number |

Name |

Function |

Quantity (set) |

|

1 |

Cell fixture |

Four cell at one time |

1 |

|

2 |

Four-station turntable |

Carry cell fixture,support the whole equipment |

1 |

|

3 |

Injection system |

store, keep,transfuse the electrolyte and remove bubbles |

1 |

|

4 |

Injection mechanism |

Vacuum injection into the opening cell |

1 |

|

5 |

Shaping&diffusion mechanism |

Vacuum diffusion°assing and shaping after electrolyte injection |

1 |

|

6 |

Pre-sealing mechanism |

Pre heat sealing the cell after diffusion°assing |

1 |

|

7 |

Frame |

Sealing, supporting |

1 |

|

Item |

Specification |

|

1.Electrolyte |

|

|

1 、component |

organic matter |

|

2、 Density |

1.0~1.5 g/cm3 |

|

2. Electrolyte |

|

|

1、Injection mode |

Vacuum injection of electric double-head pump |

|

2、Injection accuracy |

≤40g accuracy:±0.1g |

|

3、Infusion volume range |

10g-100g |

|

4、Precision of injection volume after sealing |

The accuracy of the weight after sealing and before injection can be less than (+0.2g). |

|

5、Diffusion°assing mode |

Secondary diffusion°assing, Maximum vacuum degree - 0.08 Mpa |

|

6、Diffusion°assing time |

Arbitrary setting of 1-99 seconds (Note: diffusion°assing time directly affects equipment efficiency) |

|

3.Sealing |

|

|

1、Sealing head width |

5 mm±0.1 mm (4-8mm changeable) |

|

2、Sealing head length |

170mm±0.2 mm |

|

3、Pressure |

0.1MPa~1MPa;Minimum adjustment accuracy is 0.1 MPa |

|

4、Time |

0.5s~99s;adjustable; |

|

5、Sealing head temperature |

room temperature~250℃;adjustable;accuracy:±1℃ |

|

6、Sealing performance |

Flat surface, no wrinkles, no bubbles, no stripping between the aluminium-plastic film, good sealing performance |

|

7、Sealing head material |

NAK80 |

|

8、Temperature display |

Display temperature deviation from actual temperature ±1℃ |

|

9、Temperature uniformity of sealing head |

The range of temperature distribution is less than ±2℃ |

|

10、Temperature rise speed |

It takes less than 20 minutes to rise from 25℃ to 200℃. |

|

5. Product |

|

|

1、First pass rate |

≥99% (Except for bad incoming materials, such as too short air bag to inject liquid, etc.) |

|

2、 Malfunction Rate |

≤5% |

|

3、Equipment production efficiency |

Actual production≥16PPM(Calculate according to four acceptance types of cells on each set of fixtures) |

|

Dry run≥20PPM(Calculate according to four acceptance types of cells on each set of fixtures) |

|

|

4 、Appearance |

Flatness, no wrinkles, no leakage, no drip, etc. |

|

5、Total weight of the whole machine |

About 3500 kg;Ratio of total weight to bearing area≤500kg/m2 |

|

6、Maximum size of equipment |

L*W*H:2500mm×1700mm×2450mm |

|

Water, electricity and gas requirements |

|

|

Power supply |

AC380V ±10% 50Hz/60Hz Power:6KW(self-prepared) |

|

Compressed air source |

≥0.6MPa 30L/S (Utilization ratio:50%) |

|

Drying gas source |

≥0.6MPa(User-provided drying system) |

|

Vacuum source |

≤-0.09MPa 40L/S (self-prepared) |

|

Ambient temperature |

20~50℃;Relative humidity:0~90%RH(User-provided dehumidification system) |

|

Injection pump |

Two sets of electric injection pump(self-prepared) |

Online service

Online service +86 13174506016

+86 13174506016 Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8613174506016

+8613174506016