100MWH EV Battery Prismatic Cell Manufacturing Line Machine

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-YK-FT-750Payment:

Credit Card, Paypal, T/T , Western Union, LCLead Time:

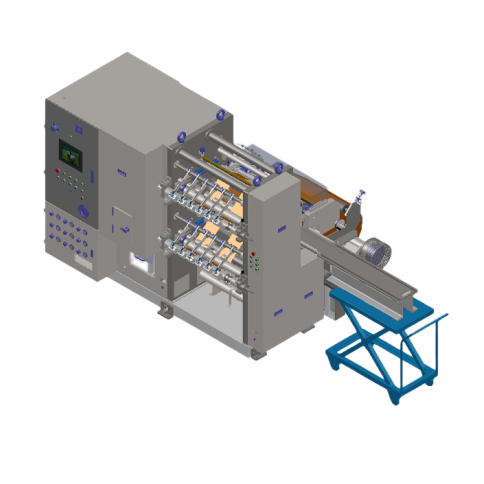

5 daysAutomatic Slitting Machine For Lithium Battery Electrode Making

1、 Equipment introduction:

1.1 Equipment function and principle introduction:

Main functions: Auto slitting machine focuses on the design and construction of lithium battery industry. The equipment is mainly used for the subsequent process of rolling, and the rolled pole slice is divided into several small rolls according to the customer's process.

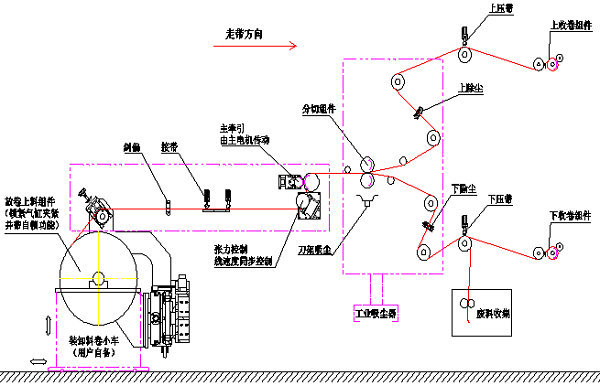

Mechanism composition: the main components of slitting are divided into unwinding mechanism, deviation correction mechanism, belt connecting platform, traction mechanism, slitting mechanism, powder brushing and dust removal mechanism, tracking roller mechanism, tablet pressing mechanism, roller pressing mechanism and winding mechanism.

Cutting principle: the full closed-loop constant tension unwinding system and active winding taper tension system are adopted, with automatic deviation correction function, and the speed of the cutter is adjustable. The whole roll of pole pieces is divided into several small rolls according to the process requirements through the transmission dust removal mechanism.

1.2 see the attached drawings for the equipment principle (for reference only)

1.3 Introduction to equipment organization:

Unwinding tension system:

This equipment adopts passive unwinding, and the tension is mainly controlled by a set of closed-loop tension control system. The pole piece passes through the tension detection roller, and after the calculation and setting results of the tension control system, the change of coil diameter does not affect the slitting effect, thus ensuring the stability of tension output. Unwinding has the function of correcting deviation. Even if the incoming material is not neatly wound within a certain range, it can be cut normally through automatic correction. The feeding mechanism adopts the top-to-top feeding method, which is humanized and easy to operate. Through the feeding car, the labor intensity is reduced and the operation safety is improved.

Tool rest structure:

It adopts Xicun type tool rest structure, and the tool diameter of 100mm or 130mm can be customized according to customers. The speed of the upper and lower knives is adjustable, and the combined spacer configuration. The lower knife adopts the flat knife design, and the upper knife sleeve adopts the adjustable knife rotation structure.

Transmission mechanism:

The transmission of this equipment mainly uses synchronous belt and synchronous belt wheel planetary reducer to realize the consistency of the speed of roller passing and guide axis. The transmission system adopts Mitsubishi servo motor. The driving rollers and components are strictly required to meet the dynamic balance requirements of less than 10 grams, which greatly reduces the vibration during the operation of the equipment and the wear of the transmission mechanism. The roll surface adopts mirror and hard anode hardening treatment. The hardness is strictly required to be about 25 degrees, which is not easy to deform, and the roll surface runout is required to be within plus or minus 0.02mm. Even if the equipment is too old, the precision of the power transmission mechanism of the equipment can be guaranteed.

Roller mechanism:

The roller pressing mechanism is mainly a metal roller with a certain hardness on the surface of multiple degrees of freedom connected by a shaft. Its main function is to ensure that the pole piece will not arch during the winding process and flatten the wavy edges produced by the strip during slitting. The pressure roller adopts the integral design, and the performance effect is better than the split design.

Electrode roll diameter tracing mechanism:

The tracking roller mechanism is mainly to ensure the evenness of the pole winding. A group of opposite edge detection optical fibers are used up and down the mechanism to detect the size and position of the coil diameter, and accurately control the distance between the tracking roller and the coil diameter. The tracking structure is driven by the motor, and the tracking roller is driven to move smoothly on the guide rail through the reducer and the gear rack connection mechanism to achieve a stable control effect. The main design intention of this mechanism has two points. The first is to make the over roll before winding as close to the winding shaft as possible, so as to reduce the swing amplitude of the material coil when entering the winding, so as to increase the uniformity of winding. The second point is mainly to detect the size of the winding diameter, so as to provide a calculation basis for the speed of the winding motor to match the belt walking speed.

Powder brushing and dust suction mechanism:

The equipment is composed of a professional industrial 2.2kW high-power turbine vacuum cleaner, and a knife set dust suction and upper and lower pole piece powder brushing dust suction mechanism, which can timely absorb the dust left on the pole piece, improve the safety of battery production and use, reduce the damage of dust particles in the production workshop to the health of employees, and improve the superiority of the working environment.

Winding mechanism:

This mechanism is mainly used for the winding of the strip after slitting. The electrical is mainly a set of Mitsubishi servo, two groups of SMC proportional valve pneumatic tension control devices, high-precision winding slip shafts up and down, which are combined by concentric torsion connecting rings. The winding shaft is locked by the cylinder pressure bar mechanism, which can better reflect the humanization of the design. The effect is more stable and convenient in operation.

2、 Configuration list of main parts and components of equipment:

|

SN |

Name |

Brand |

Origin |

|

1. |

PLC control system |

Mitsubishi |

Japan |

|

2. |

servo |

Mitsubishi |

Japan |

|

3. |

Touch screen 10 Inch color |

Weinview |

Taiwan |

|

4. |

Buttons and main control electrical components |

Schneider / Chint |

France \ domestic |

|

5. |

Tension control system |

Dongdeng |

China |

|

6. |

Deviation correction system |

Dongdeng |

China |

|

7. |

Rotary encoder |

OMRON |

Japan |

|

8. |

Proximity switches and sensors |

Daochuan |

China |

|

9. |

Pneumatic components |

AirTAC |

Taiwan |

|

10. |

Solenoid proportional valve |

SMC |

Japan |

|

11. |

linear guide rail |

TBI |

China |

|

12. |

Bearing |

HRB |

China |

|

13. |

Vacuum cleaner |

LDZW-1000 |

China |

|

14. |

Slitting blade |

Kaijin |

China |

3、 Technical parameters and factory configuration of equipment:

|

SN |

Item |

Specification |

Remark |

|

1 |

Suitable system |

Strip splitting process for positive and negative electrodes of lithium iron phosphate, lithium cobalt oxide, lithium manganate, ternary system batteries |

|

|

2 |

Operating substrate thickness |

(Al)foil: 10~30um (Cu) foil: 6~30um Including based material: 50~ 250μm |

|

|

3 |

Operating substrate width |

≥750mm |

|

|

4 |

Precision of slitting width |

±0.05 mm |

|

|

5 |

Edge quality of strip electrode |

No curling, cracks, waves, folds, powder dropping, stretching, foil exposure, obvious jagged and other quality defects |

Except for bad incoming materials |

|

6 |

Pole piece burr control |

Burr after pole slice slitting: longitudinal burr <6 um (beyond the direction of the pole piece), transverse burr <8 um (direction of pole piece) pole piece vertical detection is longitudinal, and horizontal detection is transverse. |

Depending on blade life |

|

7 |

Straightness (edge serpentine offset) |

≤±0.3mm/m |

|

|

8 |

Winding accuracy |

±0.2mm |

|

|

9 |

Slitting width |

Slitting width: above 30mm

|

Slitting width:18mm-30mm(customized) |

|

10 |

running speed |

Slitting speed≥45m/min (depends on the material) |

|

|

11 |

Tension control system |

Constant tension control,0~50N, Magnetic particle braking |

|

|

12 |

Correction method |

Auto EPC control,travel: 80mm |

|

|

13 |

Unwinding deviation correction accuracy |

±0.2 mm |

|

|

14 |

Winding diameter |

Unwinding≦Ф700mm, winding≦Ф600mm |

|

|

15 |

Maximum load of unwinding |

300Kg |

|

|

16 |

Winding shaft |

Two double slip shafts, which can rotate unilaterally, are convenient for reclaiming, and the factory configuration is suitable for the width of winding more than 35mm |

|

|

17 |

Blade material |

Alloy tungsten steel |

|

|

18 |

Slitter diameter |

Out Diameter:100mm, The upper blade can be grinded to the service outer diameter at least:Φ95mm |

|

|

19 |

Cutting width of waste edge in belt area |

≤3 mm; The double pinch rollers pinch separately, and the pinch torque is adjustable |

|

|

20 |

Pole dust collection |

After the pole slice is cut, anti-static powder brushing and vacuum cleaning are adopted |

Provide negative pressure device |

|

21 |

Blade dust collection |

Upper and lower blade installation, dusting and vacuum cleaning |

|

|

22 |

Slitting width adjustment |

Replace different spacer sleeves |

|

|

23 |

Bite amount of Slitter |

Adjust the wedge position between cutterbeds |

|

|

24 |

Number of tool holders / set |

1 set of tool rest and tool rest trolley |

|

|

25 |

an instruction manual |

1 copy with operation manual and operation instructions |

|

|

26 |

Drawing of vulnerable parts |

1set |

|

|

27 |

Drawing of vulnerable parts |

1 set |

|

|

28 |

Rolling slip bearing weight |

150kg |

|

4、 Main functions of the control system:

SN

Item

Specification

Remark

1.

Unwinding tension is adjustable

Tension range 1kg-50kg adjustable

2.

The transmission speed ratio of the cutter set is adjustable

The transmission speed ratio can be adjusted according to the cutting condition

3.

Output count

It has the function of counting the total output and the output of a single roll.

4.

Tool life memory function

Tool slitting length life memory function.

Cathode≥150000m,Anode≥300000m(depends on raw material)

5.

Speed control

With high and low speed function and adjustable speed of 1-50m/min

6.

Parameter recipe function

Parameters can be saved and called according to the model.

7.

Management permission function

It can be managed according to the operation level.

8.

Emergency stop function

In case of emergency, press emergency stop to stop quickly.

9.

Automatic shutdown function without material

It will stop automatically when there is no material in the unwinding.

10.

Fault alarm display

When a fault occurs, the corresponding alarm information and fault handling instructions pop up

11.

Undervoltage protection function

When the air pressure of the equipment is insufficient, the equipment will give an alarm.

12.

Lighting device

Lighting devices are used in key positions.

13.

IO Monitoring function

It can monitor the status of input and output signals.

14.

Deviation correction control

Deviation correction can be switched automatically and manually.

15.

Power off memory function

Relevant data and parameters can be memorized and saved in case of power failure.

5、 Commissioning tools:

|

SN |

Name |

Model |

Qty |

|

|

1 |

Wrench |

5.5-7 8-10 12-14 17-19 |

1 each |

|

|

2 |

Adjustable wrench |

300mm |

1 pc |

|

|

3 |

inner hexagon spanner |

1.5-10 |

1set |

|

|

4 |

Hook wrench |

|

1pc |

|

|

5 |

circlip pliers |

Wild card |

1pc |

|

|

6 |

bolt driver |

Straight/ cross |

1each |

|

6、 External dimension and quality of equipment:

Size: 2450×2150×1850(L×W×H) weight:3T

7、 Installation environment and supporting facilities requirements

1) Ambient temperature: =25 ℃ ± 5;

2) Relative humidity: 45 ≤ RH;

3) Ensure that the air on site is dry and unblocked;

4) Power supply: 380V, three-phase five wire system 50Hz, voltage fluctuation range: +8% - 8%;

The total power of the power supply is not less than 15KW;

5) Compressed air: after drying, filtering and stabilizing: the outlet pressure is greater than 5.0kg/cm2

Online service

Online service Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8618659217588

+8618659217588