Solid State Battery Production Lab Stacker with Triple Magazines

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-SCK200Payment:

Credit Card, Paypal, T/T , Western Union, LCLead Time:

5 days

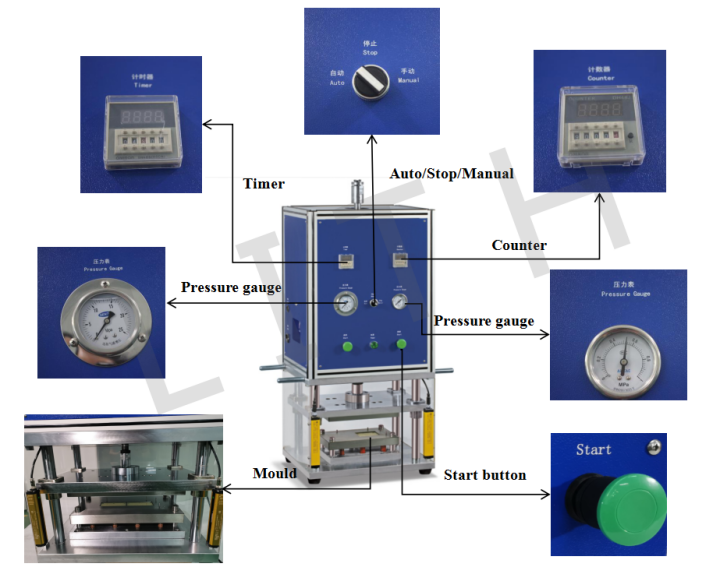

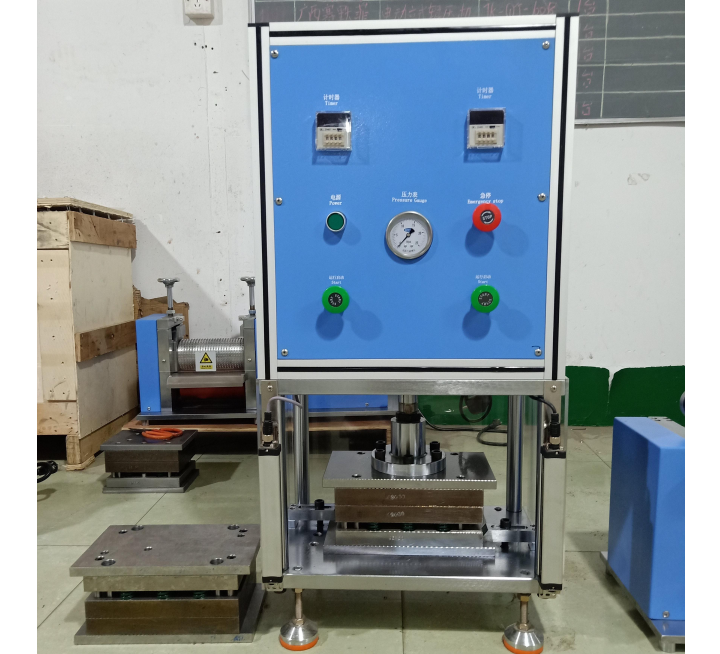

Features

1 LITH-SCK series Battery Pouch Forming Machine is used for lithium polymer battery/ pouch cell cup forming in the of making pouch cell batteries.

2 The machine is used to prepare polymer cases made of Aluminum Laminated Films.

3 This lab aluminum laminated film pouch forming machine is designed with simple Spring mold with a customized size, which is more suitable for lab research.

Technical Parameter

|

Model |

LITH-SCK200 |

LITH-SCK250 |

LITH-SCK300 |

|

Applicable specifications |

Aluminum laminated film specifications have a maximum L 180mm and a maximum W 150mm The punching depth is less than 6mm; the Pocket has no damage, and the PP layer has no wrinkles. |

Aluminum laminated film specifications have a maximum L 250mm and a maximum W 150mm The punching depth is less than 6mm; the Pocket has no damage, and the PP layer has no wrinkles. |

Aluminum laminated film specifications have a maximum L 300mm and a maximum W 280mm The punching depth is less than 6mm; the Pocket has no damage, and the PP layer has no wrinkles. |

|

Equipment capacity |

200~400EA/H |

200~400EA/H |

100~200EA/H |

|

Source voltage |

AC 220V/110V, 50/60HZ |

||

|

Power |

100W |

||

|

Warranty |

One year limited warranty with lifetime support |

||

|

Advantages |

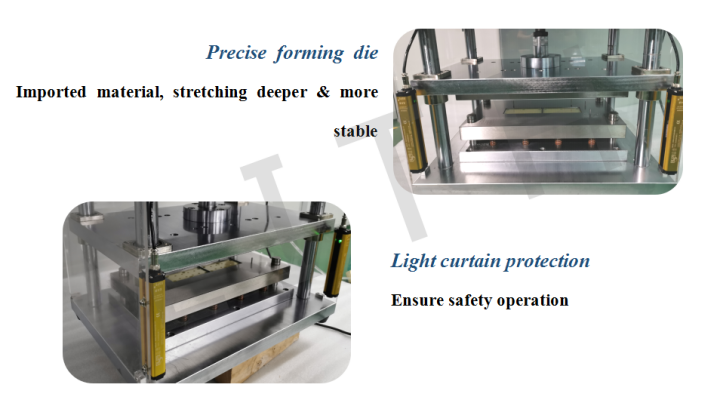

1 Structure of guide pin, slide up and down smoothly with high precision 2 Change mould, adjust tensile depth simply, quickly 3 Use screen and casing protection, guarantee safety 4 High strength of chrome steel and aluminum alloy, surface roasts the paint processing through environmental protection electroplating |

||

|

Output pressure |

5T |

||

|

Air source |

0.5-0.7MPa |

||

|

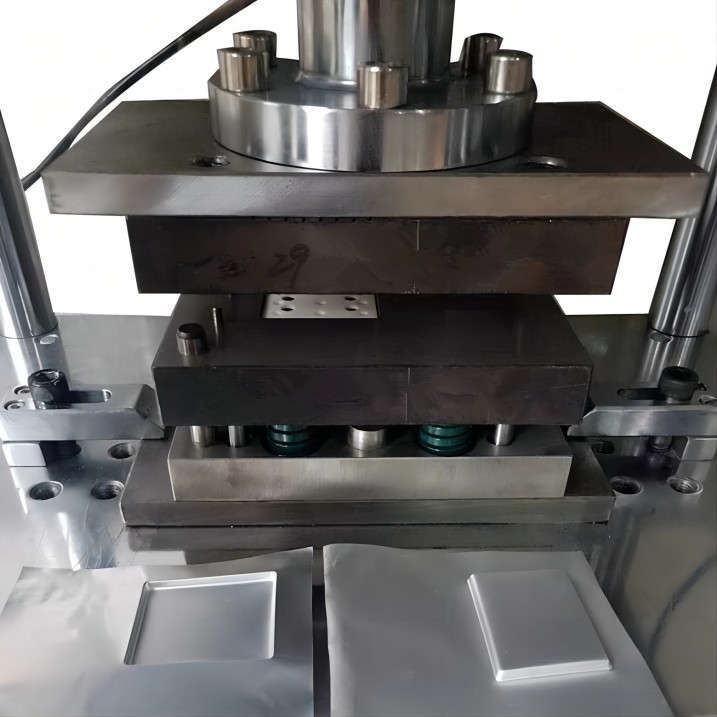

Die part |

*Mold/mold core roughness: 0.4 (mirror polished) *Flatness of upper and lower molds: 0.02mm *Mold core flatness: 0.02mm *Forming length tolerance: ±0.2 *Forming width tolerance: ±0.2 *Forming thickness tolerance: ±0.1 |

*Mold/mold core roughness: 0.4 (mirror polished) *Flatness of upper and lower molds: 0.02mm *Flatness of mold core: 0.02mm |

*Mold/mold core roughness: 0.4 (mirror polished) *Flatness of upper and lower molds: 0.02mm *Flatness of mold core: 0.02mm |

|

Dimension (L*W*H) |

460*320*925mm |

460*320*925mm |

560*420*925mm |

|

Weight |

About 130kg |

About 150kg |

About 250kg |

Online service

Online service +86 13174506016

+86 13174506016 Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8613174506016

+8613174506016