A

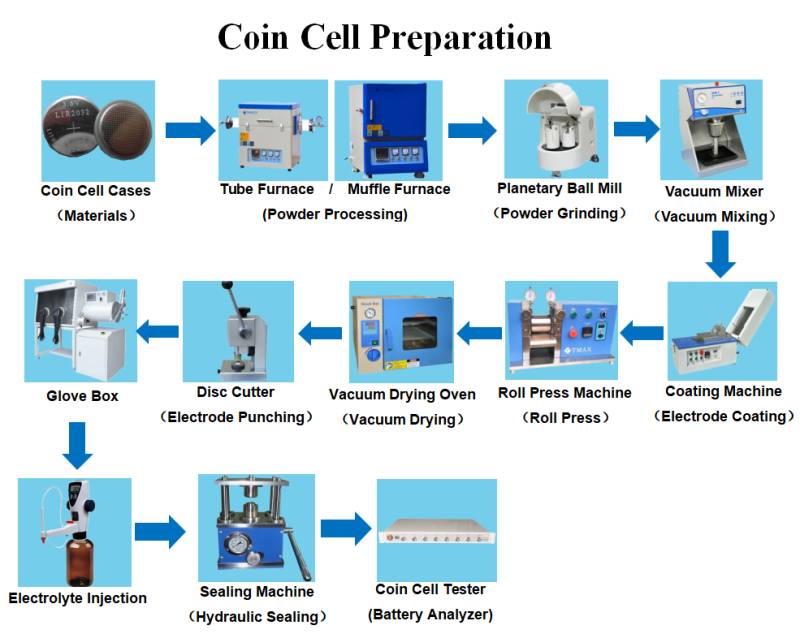

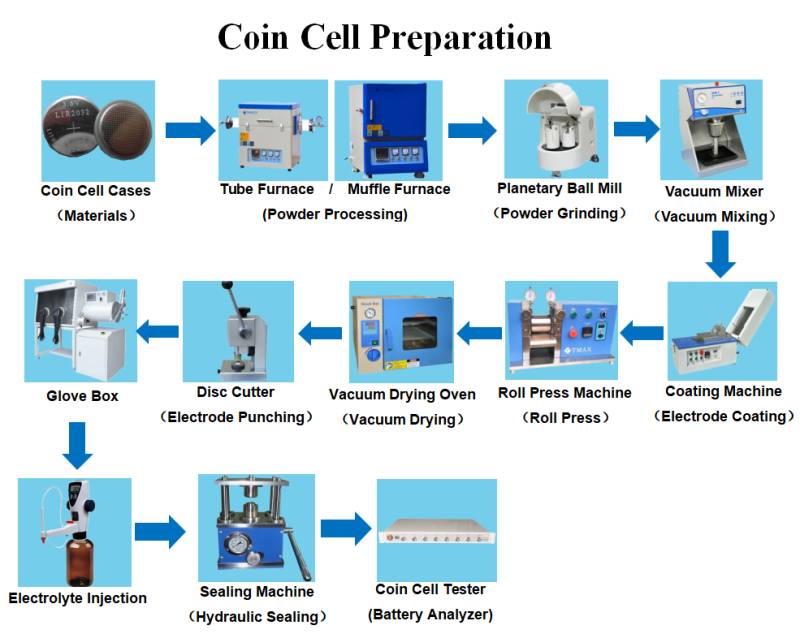

coin cell assembly line is a specialized manufacturing setup designed for the efficient production of coin cell batteries. This assembly line incorporates various processes and equipment to ensure the seamless assembly, testing, and packaging of coin cells. Let's delve into the key components and functionalities of a coin cell assembly line:

Electrode Preparation: The assembly line begins with electrode preparation, where positive and negative electrodes are fabricated. This involves coating thin layers of active materials onto metal foils, by calendering and slitting to achieve the desired electrode dimensions.

Coin cell crimper: A device that crimps the coin cell components together to form a sealed cell.

vacuum degassing mixer: A machine used to mix the electrode slurry with solvent and additives.

Film Coating Machine: A device used to evenly spread the electrode slurry onto the current collector.

Coin Cell Disc Cutter: A device that cuts the electrode into a specific shape and size.

Coin cell tester and Quality Control: Coin cells are rigorously tested for various parameters to ensure their quality and performance. This includes measuring capacity, voltage, internal resistance, and cycle life. Automated testing equipment is employed to efficiently assess a large volume of cells, ensuring adherence to strict quality standards.

Packaging: After testing, the coin cells are packaged in appropriate containers or blister packs for distribution and sale. Packaging is designed to protect the cells during transportation and storage while providing information such as specifications, safety warnings, and batch codes.

Automation and Control Systems: A coin cell assembly line incorporates advanced automation and control systems to enhance efficiency, accuracy, and productivity. These systems monitor and regulate various parameters, such as electrode alignment, electrolyte dispensing, and sealing integrity, ensuring consistent and reliable production.

Safety Measures: Safety is paramount in a coin cell assembly line. Measures such as ventilation systems, fire protection systems, and employee training on safe handling of materials and equipment are implemented to mitigate risks and ensure a secure working environment.

A well-designed coin cell assembly line enables high-speed and high-quality production, ensuring reliable and consistent performance of coin cell batteries. It optimizes productivity, reduces production costs, and meets the growing demand for coin cells in applications like portable electronics, medical devices, and IoT devices.

Online service

Online service