A

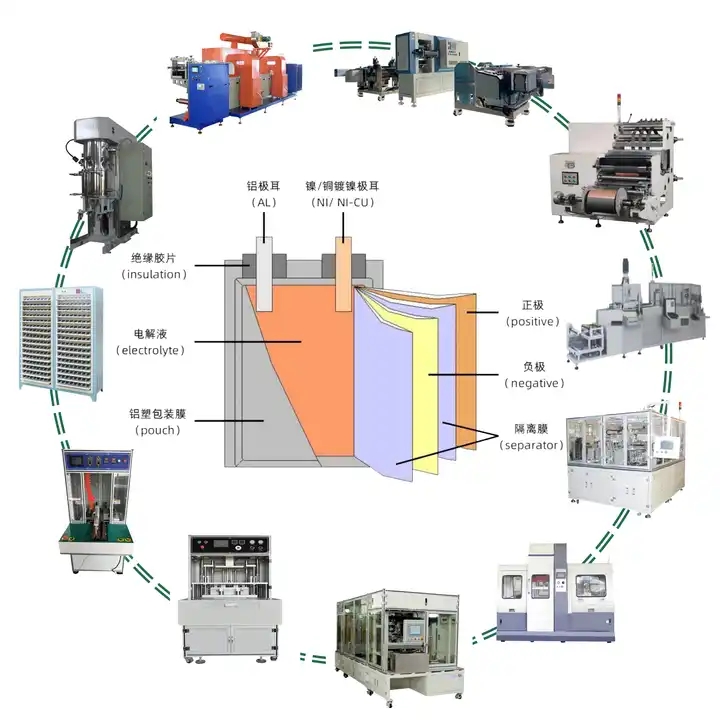

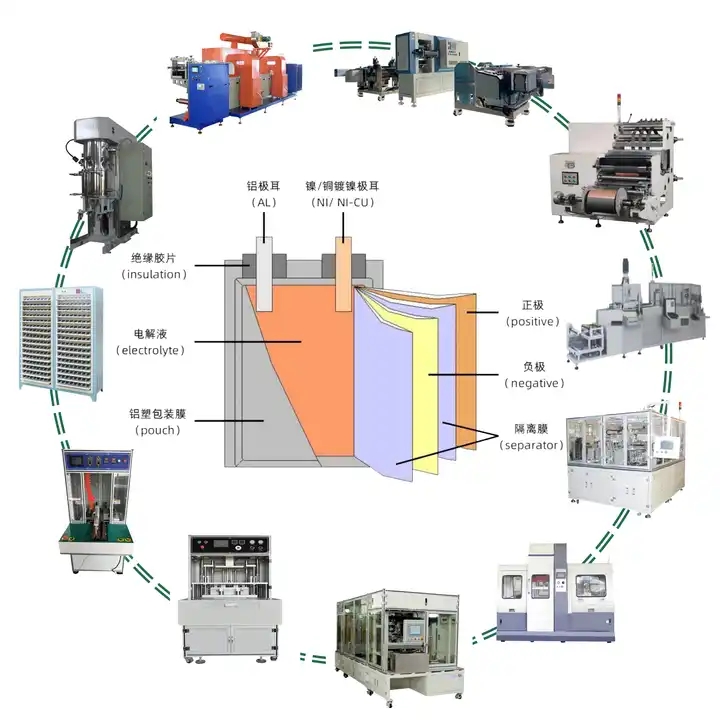

pouch cell manufacturing plant is a specialized facility designed for the mass production of pouch-type lithium-ion batteries. It encompasses a series of processes and equipment to efficiently produce high-quality pouch cells. Let's explore the key components and features typically found in a pouch cell manufacturing plant:

-

Electrode Coating: This process involves applying electrode materials, such as cathode and anode, onto current collector foils. Electrode Coating machines ensure uniform and precise coating thickness to enhance battery performance.

-

Electrode Drying: After coating, the electrode materials need to be dried to remove solvents. Electric drying ovens or chambers are utilized to evaporate the solvents and create a stable electrode structure.

-

Electrode Cutting: The coated electrode foils are cut into specific sizes to match the desired dimensions of the pouch cells. Electrode cutting machines ensure accurate and efficient cutting of the electrodes.

-

Separator Handling: Pouch cells require a separator material to separate the anode and cathode. Separator handling equipment facilitates the handling and placement of the separator material during cell assembly.

-

Pouch Cell Assembly: This process involves stacking the coated electrodes and separator layers, along with electrolyte, to form the pouch cell structure. Assembly machines ensure precise alignment and stacking of the components.

-

Electrolyte Filling: Pouch cells require the injection of electrolyte, a conductive solution, to enable ion transport. Electrolyte filling machines ensure accurate and controlled filling of the electrolyte into the assembled cells.

-

Cell Sealing: Once the electrodes and electrolyte are assembled, the pouch cells need to be sealed to prevent leakage. Sealing machines apply heat and pressure to create a secure and leak-proof seal.

-

Formation and Testing: The manufacturing plant includes equipment for cell formation, which involves initial charging and discharging cycles to activate the cells. Testing equipment is used to assess various cell parameters, such as capacity, voltage, and internal resistance, ensuring quality control.

-

Safety Measures: Pouch cell manufacturing plants incorporate safety measures to handle and mitigate risks associated with hazardous materials and processes. This includes safety protocols, ventilation systems, fire suppression systems, and safety equipment.

A pouch cell manufacturing plant enables efficient and large-scale production of pouch-type lithium-ion batteries. The streamlined processes and specialized equipment ensure consistent and reliable battery performance. With stringent quality control measures, the plant can produce high-quality pouch cells for various applications, including portable electronics, electric vehicles, and energy storage systems.

Online service

Online service