A

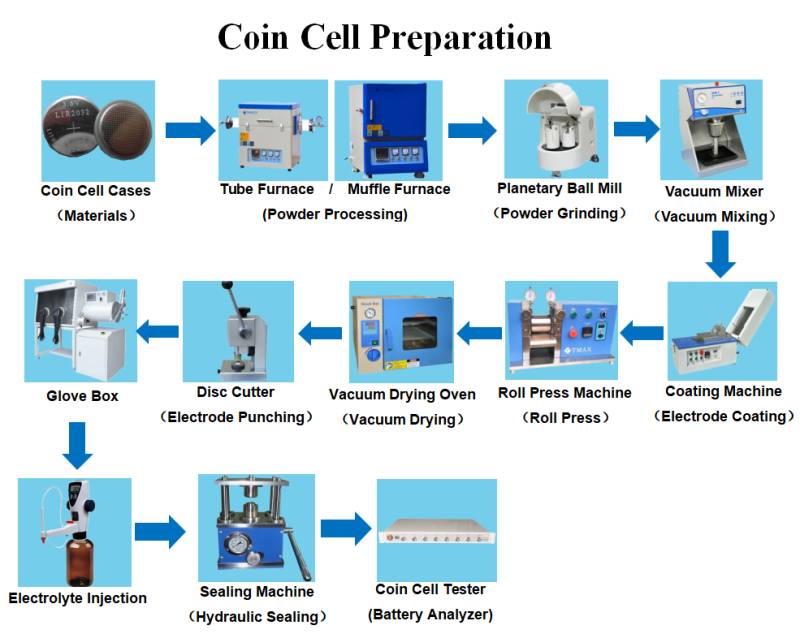

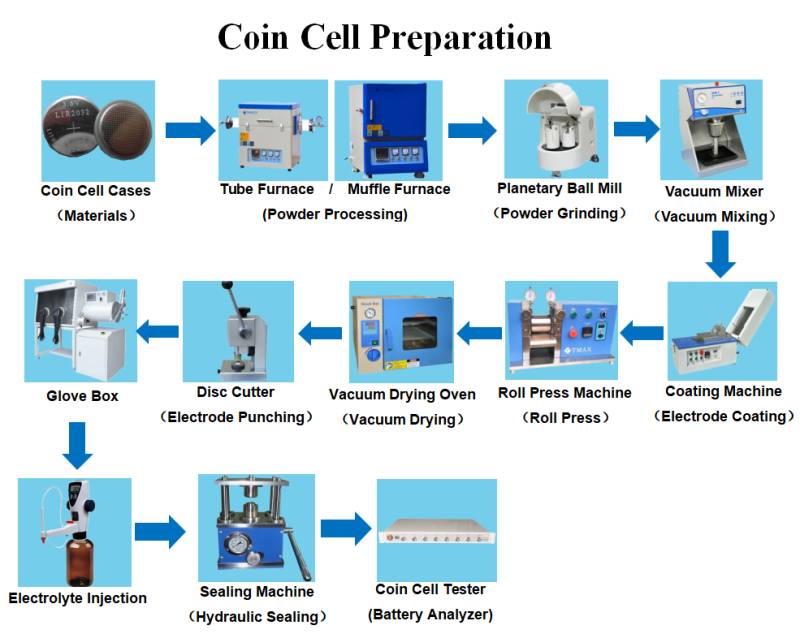

Coin Cell Assembly Machine is a specialized piece of equipment used for the automated assembly of coin cell batteries. It is designed to streamline and enhance the production process by automating various steps involved in coin cell assembly. Here are some key features and functions of a typical Coin Cell Assembly Machine:

Electrode Stacking machine : The machine is equipped with precision alignment mechanisms to stack positive and negative electrodes accurately. It ensures proper alignment and uniform compression to achieve consistent electrode performance.

Tab Welding: The machine employs advanced welding techniques, such as spot welding or laser welding, to securely attach the tab onto the electrode stack. This ensures reliable electrical connections and enhances the overall performance of the coin cell.

Separator Placement: It incorporates a mechanism to precisely place the separator material between the positive and negative electrodes. The separator acts as an insulating layer and facilitates ion transport within the cell.

Electrolyte Filling machine : The machine is equipped with a precise dispensing system to accurately fill the electrolyte into the assembled cell. It ensures the optimal electrolyte volume for proper cell function.

Cell Sealing: It incorporates a sealing mechanism to hermetically seal the assembled cell, ensuring a leak-proof and durable enclosure. This helps to maintain the integrity of the cell and prevent electrolyte leakage.

Cell Testing: The machine may include built-in testing capabilities to measure key parameters such as voltage, capacity, and internal resistance of the assembled coin cell. This allows for real-time quality control and identification of any faulty cells.

Automation and Control: Coin Cell Assembly Machines are typically fully automated and programmable. They can be integrated into a production line and controlled via a user-friendly interface. The machine may have options for customization based on specific coin cell specifications.

Benefits of using a Coin Cell Assembly Machine:

Increased Efficiency: Automation reduces manual labor and speeds up the assembly process, resulting in higher production output and improved efficiency.

Consistency and Quality: The machine ensures consistent assembly and accurate electrode alignment, leading to consistent cell performance and improved product quality.

Precision and Reliability: The use of advanced welding and sealing techniques ensures precise and reliable connections, minimizing the risk of electrode detachment or electrolyte leakage.

Cost Savings: By reducing manual labor and minimizing errors, a Coin Cell Assembly Machine helps to optimize production costs and maximize overall profitability.

Scalability: These machines are designed to handle different sizes and types of coin cells, offering flexibility and scalability to adapt to changing production needs.

In conclusion, a Coin Cell Assembly Machine plays a crucial role in the efficient and reliable production of coin cell batteries. It automates various assembly steps, improves consistency, and enhances overall product quality, making it an essential piece of equipment for battery manufacturers.

Online service

Online service