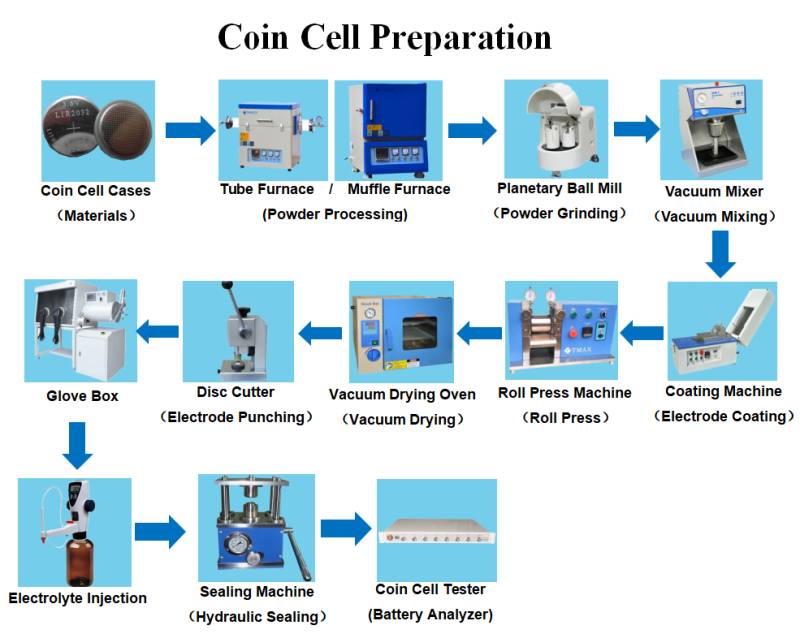

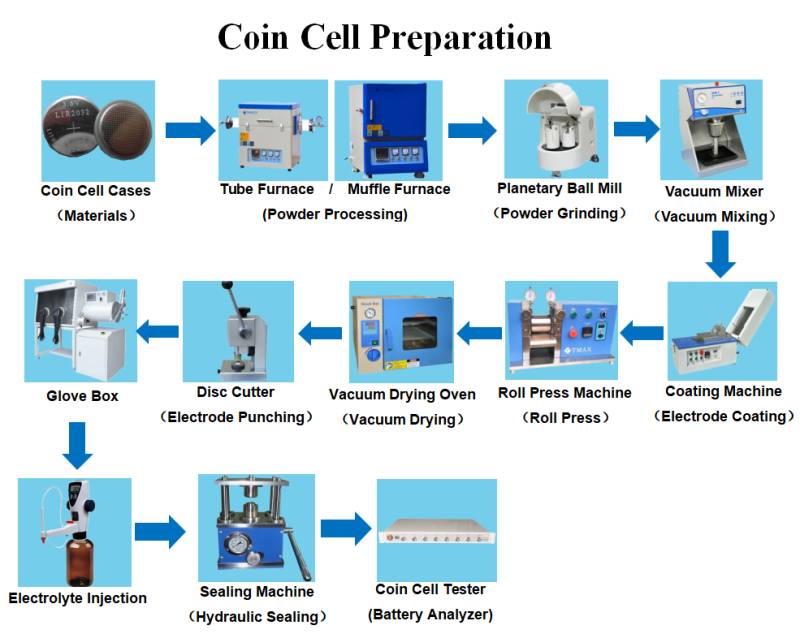

Exploring button Cell Lab Equipment for Battery Research

Introduction:

Coin cell batteries are widely used in portable electronics, medical devices, and various other applications. In order to conduct research and development on coin cell batteries, specialized lab equipment is required. This blog post will provide an overview of the essential coin cell lab equipment and their functions, highlighting their significance in battery research.

button Cell Lab plant

Coin cell assembly is a crucial step in the fabrication of coin cell batteries. The following equipment is commonly used:

Coin Cell Cases: These are typically made of stainless steel or other suitable materials. They provide the structure and containment for the battery components.

Coin Cell Assembly Jigs: These jigs hold the components of the coin cell, including the electrode, separator, and electrolyte, in place during assembly. They ensure precise positioning and alignment.

Electrode Preparation Equipment:

Preparing the electrode materials is a key aspect of coin cell fabrication. The following equipment is used:

Coating Machine: This machine applies electrode materials, such as the anode and cathode, onto current collector foils. It ensures a uniform and precise coating thickness, which is essential for battery performance.

Drying System: After coating, the drying system removes solvents from the coated electrodes, ensuring proper adhesion and stability.

Electrode Cutting and Slitting Equipment:

To achieve the desired dimensions for the coin cell electrodes, the following equipment is employed:

Cutting Machine: This machine cuts the coated electrode sheets into the desired dimensions that match the size of the coin cell.

Slitting Machine: It divides the electrode materials into narrower strips for electrode winding or stacking.

Electrode Winding and Stacking Equipment:

The electrode winding or stacking process involves the following equipment:

Winding Machine: It rolls the positive and negative electrode strips together with separators to form tightly wound electrode assemblies, known as jelly rolls.

Stacking Machine: This machine stacks multiple layers of positive and negative electrodes, separated by electrolyte-soaked separator films, to create the final electrode assembly.

Coin Cell Testing and Characterization Equipment:

To evaluate the performance and characteristics of coin cell batteries, the following equipment is utilized:

Performance Testing Instruments: These instruments measure critical parameters such as voltage, capacity, internal resistance, cycle life, and self-discharge rate. They provide insights into the battery's performance and behavior.

Impedance Spectroscopy Analyzer: It analyzes the electrochemical behavior of coin cells by measuring their impedance response across a range of frequencies.

Differential Scanning Calorimetry (DSC): DSC analysis determines the thermal properties, including specific heat capacity, phase transitions, and reaction kinetics of the coin cell components.

Conclusion:

Coin cell lab set up

plays a vital role in battery research, enabling scientists and engineers to fabricate, test, and characterize coin cell batteries. From assembly and electrode preparation to testing and characterization, each equipment fulfills a specific function in the battery research process. By utilizing these specialized tools, researchers can gain valuable insights into battery performance, enhance battery design, and contribute to the advancement of energy storage technology.

Online service

Online service