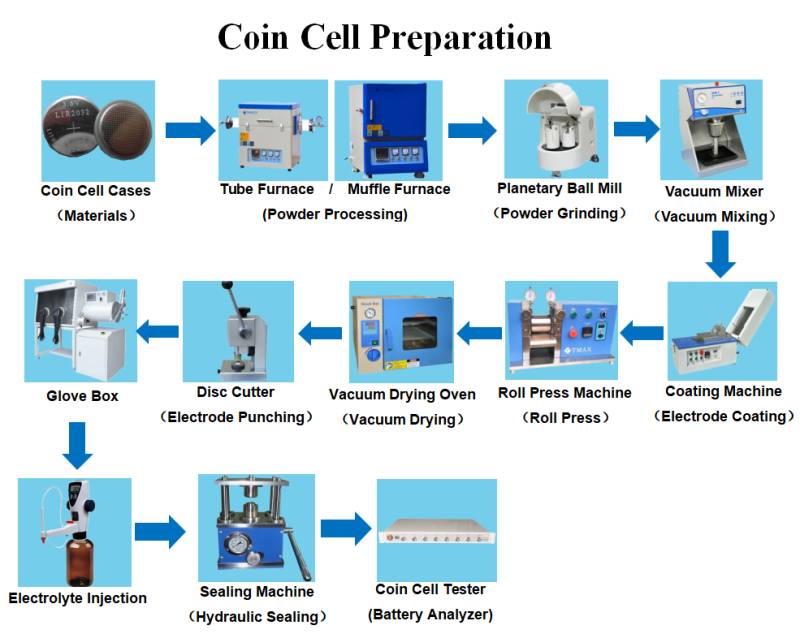

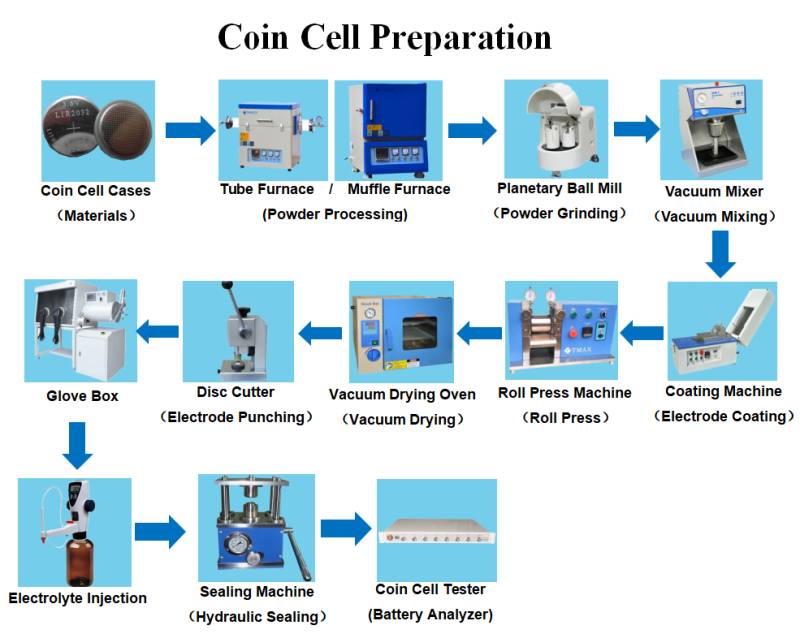

The assembly steps for button cell assembly Line are as follows:

Electrode Preparation:

a. Coating: Apply the electrode materials (anode and cathode) onto current collector foils using a coating system. Ensure uniform coating thickness.

b. Drying: Remove solvents from the coated electrodes using a drying system, ensuring proper adhesion and enhancing stability.

c. Electrode Calendering: Compress the electrode materials to the desired thickness using a calendering system, improving energy density and uniformity.

Electrode Cutting and Slitting:

a. Cutting: Use a cutting machine to cut the coated electrode sheets into desired dimensions that match the coin cell size.

b. Slitting: Divide the electrode materials into narrower strips using a slitting machine for electrode winding or stacking.

Electrode Winding or Stacking:

a. Winding: Roll the positive and negative electrode strips together with separators to form a tightly wound electrode assembly (jelly roll) using a winding machine.

b. Stacking: Stack multiple layers of positive and negative electrodes, separated by electrolyte-soaked separator films, to form an electrode assembly using a stacking machine.

Coin Cell Assembly:

a. Placement: Use a coin cell assembly machine to place the electrode assembly, along with separator discs and electrolyte-soaked separator layers, into coin cell cases.

b. Sealing: Seal the coin cell cases by crimping the edges using a coin cell crimping machine, ensuring proper sealing and preventing electrolyte leakage.

Coin Cell Testing and Characterization:

a. Performance Testing: Measure critical parameters such as voltage, capacity, internal resistance, cycle life, and self-discharge rate using testing instruments to evaluate the performance and characteristics of the coin cells.

b. Impedance Spectroscopy: Conduct impedance spectroscopy to analyze the electrochemical behavior of the coin cells by measuring their impedance response over a range of frequencies.

c. Differential Scanning Calorimetry (DSC): Perform DSC analysis to determine the thermal properties, such as specific heat capacity, phase transitions, and reaction kinetics, of the coin cell components.

Safety Measures and Quality Control:

a. Incorporate safety features such as pressure relief vents and thermal protection to ensure safe operation and prevent potential hazards.

b. Implement quality control stations to monitor and inspect button Cell lab Line, dimensions, and performance to ensure adherence to quality standards and specifications.

Online service

Online service +86 13174506016

+86 13174506016