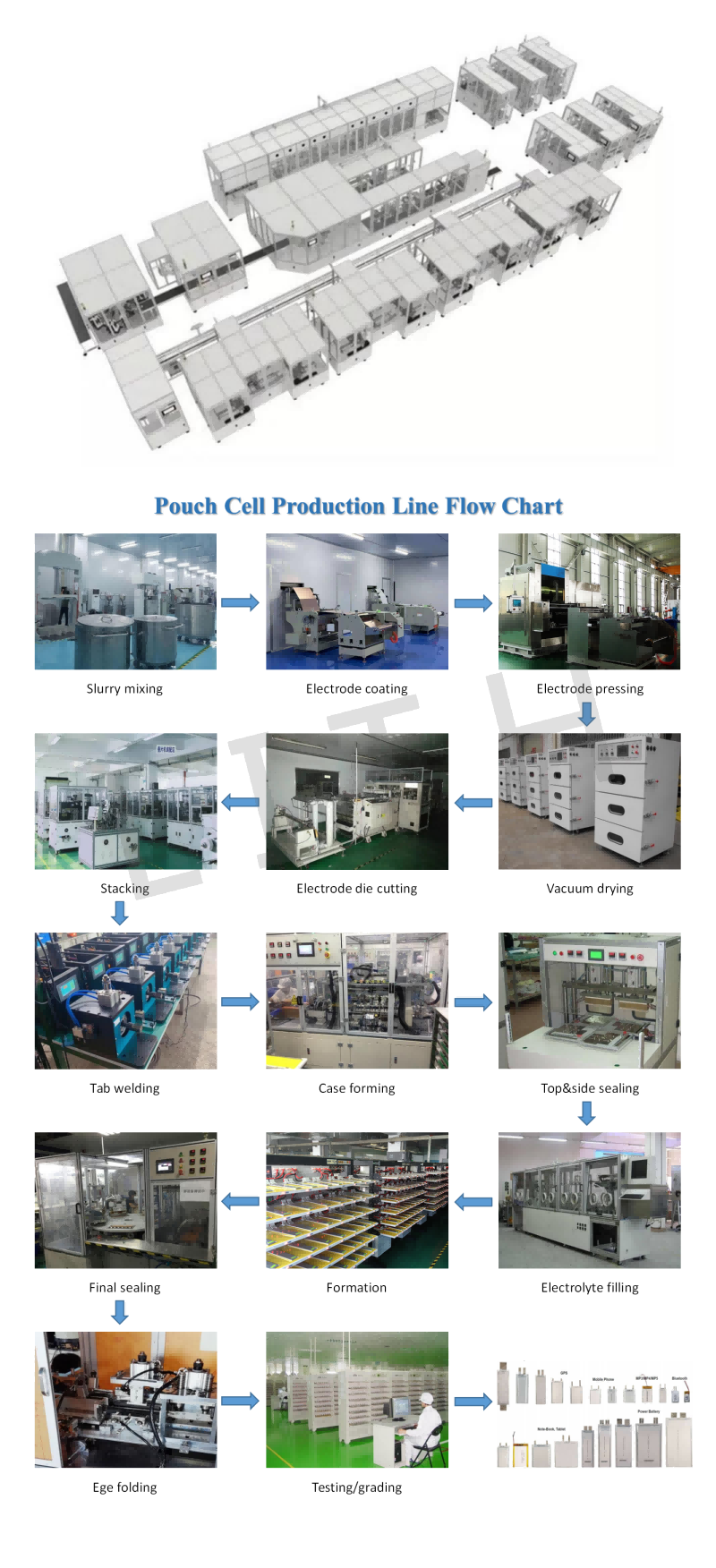

A pouch battery pilot line is a specialized facility or setup designed for the production and testing of pouch cells on a pilot scale. Pouch cells are a type of lithium-ion battery that feature a flexible and lightweight design, making them suitable for various applications. A pouch cell pilot plant serves as an intermediate step between laboratory-scale research and full-scale commercial production. Here are some key components and functions typically found in a pouch cell pilot plant:

Electrode Preparation:

Coating System: This equipment applies electrode materials (anode and cathode) onto current collector foils, ensuring precise and uniform coating thickness.

Drying System: Removes solvents from the coated electrodes, ensuring proper adhesion and enhancing the electrode's stability.

Electrode Cutting and Slitting:

Cutting Machine: Cuts the coated electrode sheets into desired dimensions to match the pouch cell size.

Slitting Machine: Divides the electrode materials into narrower strips for electrode stacking.

Electrode Stacking and Lamination:

Stacking Machine: Stacks multiple layers of positive and negative electrodes, separated by electrolyte-soaked separator films, to form an electrode assembly.

Lamination Machine: Applies heat and pressure to the electrode assembly, ensuring proper adhesion and creating a stable and uniform structure.

Pouch Cell Assembly:

Pouch battery Scale line : Places the electrode assembly into a flexible pouch, typically made of aluminum or polymer laminate.

Sealing Machine: Seals the pouch cell by heat sealing the edges, ensuring proper sealing and preventing electrolyte leakage.

Electrolyte Filling:

Electrolyte Filling System: Injects the appropriate electrolyte into the sealed pouch cell, ensuring optimal ion conductivity and facilitating electrochemical reactions.

Pouch Cell Formation and Testing:

Formation Process: Subjects the pouch battery lab line to an initial charge and discharge cycle to activate and stabilize their electrochemical properties.

Testing Instruments: Measure critical parameters such as voltage, capacity, internal resistance, and cycle life to evaluate the performance and quality of the pouch cells.

Safety Measures and Quality Control:

Safety Features: Incorporate safety mechanisms such as pressure relief vents and thermal protection to ensure safe operation and prevent any potential hazards.

Quality Control Stations: Monitor and inspect pouch cell characteristics, dimensions, and performance to ensure adherence to quality standards and specifications.

Data Collection and Analysis:

Data Logging Systems: Collect and record real-time data during the production and testing processes. This data can be analyzed to optimize production parameters, enhance performance, and improve overall efficiency.

Scalability and Transferability:

The processes and parameters validated in the pouch cell pilot plant can be easily transferred to full-scale commercial production. This ensures consistency in manufacturing and facilitates a smooth transition from pilot production to large-scale production.

A pouch cell pilot plant enables the production of pouch cells on a larger scale than the laboratory, allowing for more accurate evaluation of their performance and quality. It serves as a critical step in the development and optimization of pouch cell battery technology before full-scale commercial production.

Online service

Online service