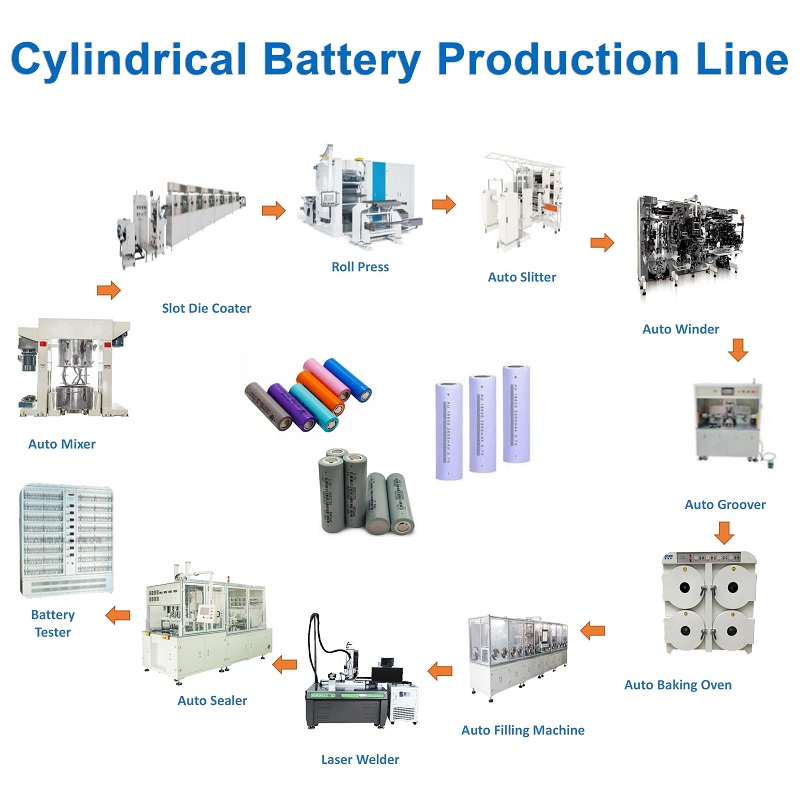

Automatic 18650/21700/26650/32650/32700 Cylindrical Cell Production Equipment Plant For Li-ion Battery Fabrication

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-XHPT-5063-MMPayment:

Credit Card, Paypal, T/T , Western Union, LCShipping port:

Xiamen PortLead Time:

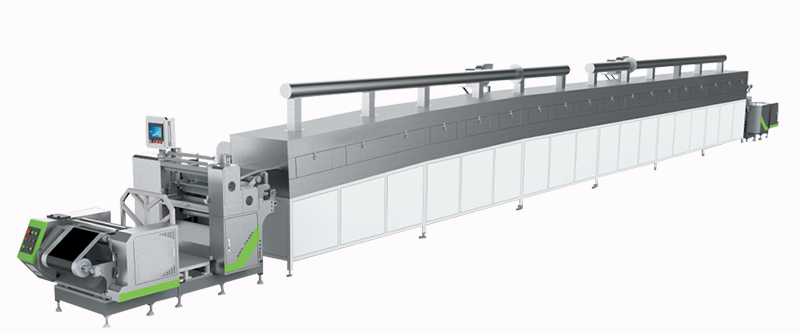

5 daysPrecision Extrusion Single Side Slot Die Coating Machine For Li-ion Battery Production

1. Process Flow

The base material of the polar plate placed on the unwinding device enters the unwinding tension system after automatic correction, and enters the coating head after adjusting the unwinding tension. The polar plate is coated according to the setting procedure of the coating system. The coated wet electrode piece enters the oven and is dried by hot air. The tension of the dried pole piece is adjusted by the tension system, and the winding speed is controlled to synchronize with the coating speed. The pole piece is automatically rectified by the rectifying system to keep it in the set position, and is wound by the winding device.

2. Equipment Composition

1) Unwinding mechanism

2) Coating mechanism

3) Oven

4) Export rectifying mechanism

5) Discharge mechanism

6) Winder mechanism

7) Electrical control system

8) Precision feeding system

3. Main Parameter

|

NO. |

Project |

Parameter |

Remarks |

|

1 |

Normal Speed of Coating |

≤24m/min |

Normal coating speed is related to material system, coating thickness and solid content |

|

2 |

Coating Speed Accuracy Error |

≤0.1m/min |

|

|

3 |

Coating Width |

≤650mm |

|

|

4 |

Coating Length (Single Piece) |

≤2500mm |

|

|

5 |

Coating Machine Speed |

40m/min |

|

|

6 |

Overall Length of Coater |

≤43m |

It has a great relationship with configuration |

|

7 |

Equipment Air Pressure |

0.6~0.8 MPa |

Dry and free of impurities |

|

8 |

Single Side Coating Dry Thickness Error |

Li(NiCoMn)O2, LiFePO4, Cobalt±2μ (Mn±2μ) |

Edge, head and tail 8mm are excluded |

|

9 |

Double Side Coating Dry Thickness Error |

Li(NiCoMn)O2, LiFePO4, Cobalt±3.0μm (Mn±3μ) |

|

|

10 |

Single Side Weight Error in Single Chip |

±1.5% |

Measurement method (Fig. B) |

|

11 |

Minimum Coating Length |

20mm |

|

|

12 |

Minimum Length Dimension of Single Pole Piece |

50mm |

(One coating plus gap) |

|

13 |

Minimum Length Dimension of Single Double Segment Pole Piece |

100mm |

(Two coatings plus gap) |

|

14 |

Single Side Thickness Error of Electrode Head and Tail |

-10μm~ +5μm |

|

|

15 |

Interval Coating Minimum Gap |

10mm |

With the coating speed, the faster the speed, the greater the minimum gap. |

|

16 |

Accuracy Error of Coating Length |

±1.0 mm |

Within 3000mm |

|

17 |

Overlap Error of Front and Back Coating |

±0.5 mm |

|

|

18 |

Overlap Error of Front and Back Coating Edge |

±0.5 mm |

|

|

19 |

Edge Uniformity Error of Winding |

± 1 mm (start calculation after 5 turns) |

Φ 500mm roll |

Online service

Online service +86 13174506016

+86 13174506016 Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8613174506016

+8613174506016