Solid State Battery Production Lab Stacker with Triple Magazines

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-VS-40APayment:

Credit Card, Paypal, T/T , Western Union, LCLead Time:

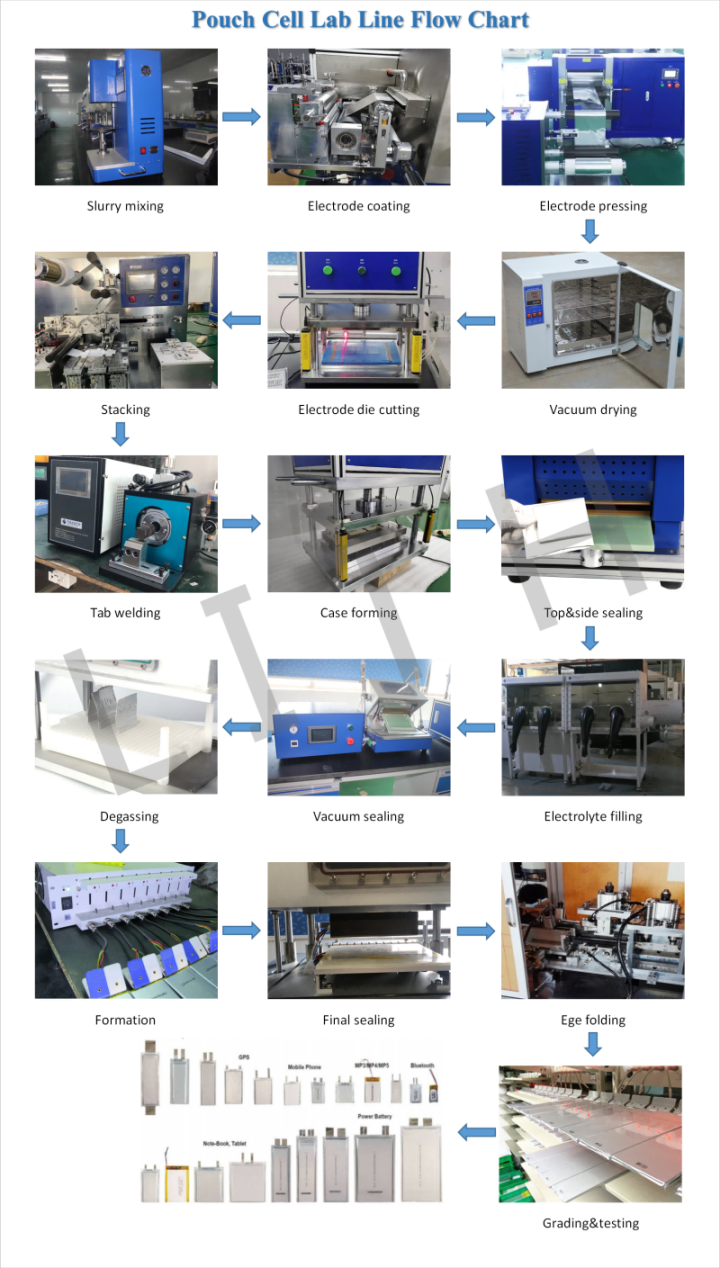

5 daysSolid State Battery Tab Ultrasonic Metal Spot Welder For Electrode Welding

Introduction

LITH-VS-40A ultrasonic spot welder is generailly used for battery winding and stacking process of metal welding. It has some features, such as: small in size, beautiful appearance, convenient operation, compact structure, stable and safety use and so on. The welding principle is: the transducer converts the ultrasonic frequency high-power oscillating signal into mechanical energy of the corresponding frequency, and adds it to the interface of the metal sheet to be welded, so that the metal sheet meets instant heat, thereby activating the particles in the metal lattice. So that the molecules where the metal sheets meet each other infiltrate and weld them together.

Main features

*The solder joints are firm. The working temperature does not exceed its annealing temperature, and would not change the metallographic structure of the workpiece, and its welding strength

*The welding is firmer than other methods, and the welding interface is neat and clean

*Good conductivity after welding, and its resistivity is extremely low, close to zero

*All workpieces can be welded without pre-treatment, no soldering tin, soldering oil additives, economical and convenient

*The welding time is very short. Generally, the welding can be completed in an instant within 0.01-2s.

Technical parameters

|

Features |

Preset welding programs selectable for Al and Cu (Note: Welding power can be readjusted to fit the needs for welding other types of metals such as Au, Fe, Ni, Ag...). |

|

Input Voltage |

AC 110V or 220V +/-10%, 50/60Hz |

|

Max. Power Consumption |

2000W→can be customized |

|

Welding Area |

4mm(L) x 4mm(W) → can be customized |

|

Welding Head |

The welding heads and welding base are included for welding both aluminum & copper current collectors from 2 to 25 layers |

|

Ultrasonic Frequency |

40K Hz → can be customized |

|

Product Dimensions |

1. Controller: 360mm(L) x 480mm(W) x 200mm(H) 2. Welder: 200mm(L) x 460mm(W) x 270mm(H) |

|

Net Weight |

50kg |

|

Compliance |

CE Certificate |

|

Warranty |

One Year limited warranty with lifetime support |

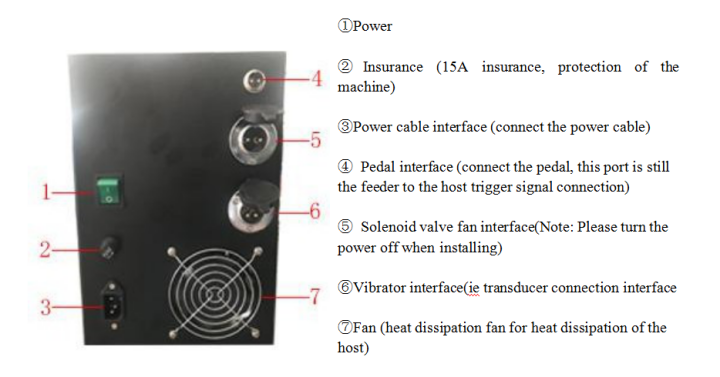

Main components

Controller, ultrasonic horn, transducer, welding head, pneumatic mechanism and fixture.

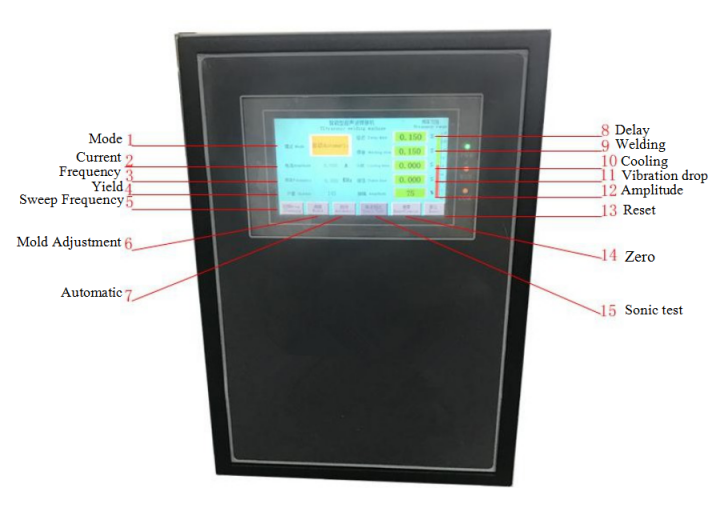

Controller

①Mode (With automatic, mode adjustment two modes)

Adjust the automatic mode when working, and adjust the mode when changing the mold.

②Current

The actual current amount per work, reflecting the power of the machine, this item is not adjustable.

③Frequency

The frequency of automatic tracking of the machine at each work ensures the stability of the machine. This item cannot adjusted.

④Yield

Counting effect, the number is increased by 1 for each work

⑤Sweep Frequency

For the frequency calibration between the generator and the welding head, the vibrator, press the sweep button when replacing the welding head, the generator will automatically match with the vibrator and the frequency of the welding head

⑥Mold Adjustment

For mold replacement

⑦Automatic

Press automatic when welding the material, the machine starts running

⑧Delay

It refers to the time between the welding head descending to the sound wave, during which the sound generator does not emit ultrasound. This project can be adjusted according to the actual welding material.

⑨Welding

The generator emits the sonic time, this item can be adjusted according to the actual work.

⑩Cooling

The time when the welding head stays on the welding material after the completion of acoustic wave, this item can be adjusted.

⑪Vibration drop

The generator's secondary sounding time, to prevent the welding material from sticking to the welding head, this item can be adjusted according to the actual work.

⑫Amplitude

Adjust the power of the machine, this project can be adjusted according to the actual work settings

⑬ Reset

Remove overload by reset when machine overloads. Light touch reset button to trigger alarm.

⑭Zero(Clear capacity count)

Clear capacity by touching the zero-clearing button

⑮Sonic test

Test whether the sounder is pronounced, current, frequency is normal.Touch the sound wave test button to test the sound wave

Online service

Online service +86 13174506016

+86 13174506016 Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8613174506016

+8613174506016