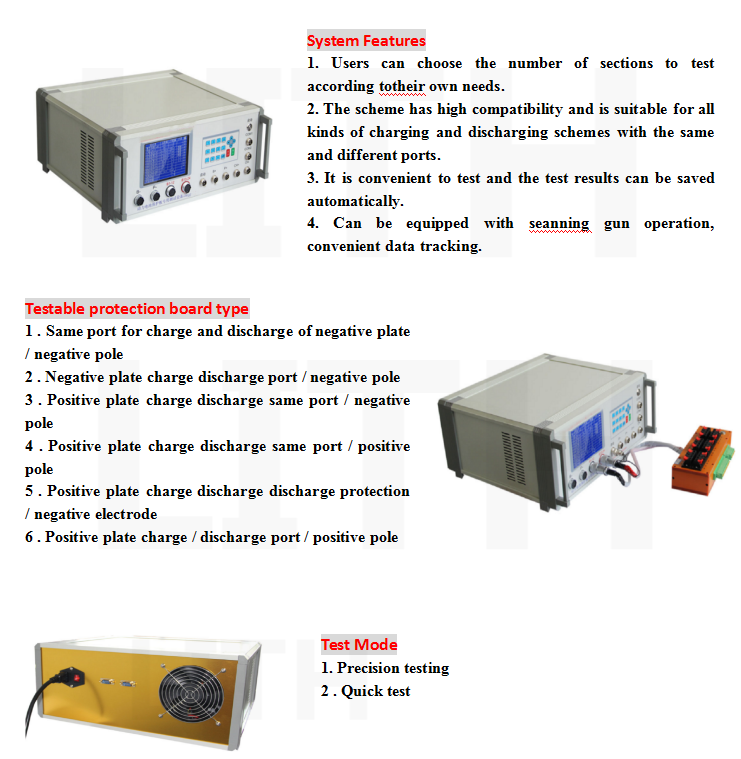

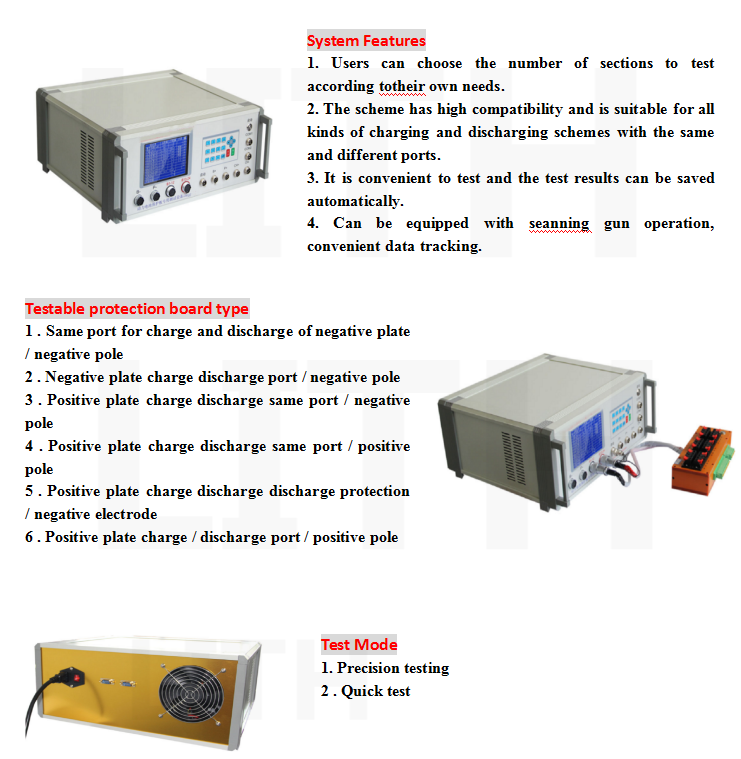

1-32 Series 150A (Overcurrent)Lithium Battery Protection Board Tester Battery Management System Tester BMS Testing Machine

1. Application and Function Introduction

1.1 Application: It is mainly used to detect whether the functional indexes of power battery

protection board are within the parameter range, so as to provide a set of detection standards for

staff. It is mainly used for the test of power battery protection board of protection board

manufacturers and power battery manufacturers.

1.2 Function Introduction: PBTS protection board test system is divided into fast test and

accurate test

Accurate test: It can accurately detect the accurate value of various functional parameters of

the power battery protection board (the error is 5mv), facilitate the debugging and development

of samples, and provide a set of standards for rapid detection for R & D personnel.

Quick test: According to the design parameters of the protection board, set the test parameters

to conduct quick test, which is convenient for the protection board manufacturer and power

battery manufacturer to conduct large-scale and rapid test and delivery. It is also applicable to

the protection board test of various hardware schemes and some software schemes.

2. Main Performance

2.1 Routine test items:

Internal resistance test, overcharge and discharge test, overcharge recovery, overcharge and

discharge recovery test, overcurrent test (Charging overcurrent and discharge overcurrent),

overcharge protection voltage, overcharge recovery voltage, overcharge and discharge

protection voltage, overcharge recovery voltage, overcurrent protection, etc.

2.2 Special test items:

Short circuit protection test (Refers to the real short circuit protection test of microsecond level).

Single section self power consumption test (Refers to the true and accurate self power

consumption of each section).

Equalizing current and equalizing voltage (Can accurately grasp the equalizing current and

equalizing opening voltage).

Infrared scanning (Bar code scanning) scans the ID number of each protection board and stores

the record.

3. Technical Parameter

3.1 High current module: The current level is 150A and the current accuracy is 0.1A.

3.2 Voltage module: Voltage range 0.5-5V, programmable output 0.5-5V, voltage accuracy

5mV.

3.3 Short circuit module: Super capacitor, which fully simulates the pack battery voltage,

instantly short circuits the protection board, and accurately captures the short-circuit time and

current.

|

Test Items

|

Test Scope

|

Accuracy

|

|

Number of test series

|

1-24 series

|

|

|

Reference voltage

|

LiCoO2(3.8V) LiFePO4(3.0V)

|

|

|

Overcharge protection voltage

|

0.5-5V

|

±5mV

|

|

Over discharge protection voltage

|

0.5-5V

|

±5mV

|

|

Overcharge recovery voltage (Self recovery)

|

0.5-5V

|

±5mV

|

|

Over discharge recovery voltage (Self recovery)

|

0.5-5V

|

±5mV

|

|

Overcharge protection current

|

1-40A

|

±0.1A

|

|

Over discharge protection current

|

1-150A

|

±0.1A

|

|

Equalizing opening voltage

|

0.5-5V

|

±5mV

|

|

Equalizing real-time current

|

0-1000mA

|

±1mA

|

|

Overcurrent protection delay

|

0-15S

|

±1mS

|

|

Overcharge protection delay

|

0-20S

|

±1mS

|

|

Over discharge protection delay

|

0-20S

|

±1mS

|

|

Single section self power consumption

|

0-500uA

|

±1uA

|

|

Loop internal resistance

|

0-500mΩ

|

±1mΩ

|

|

Short circuit protection (More than 6 series)

|

0-9999us

|

±1uS

|

|

Application

|

All hardware scheme protection boards and some software boards in the market (Special

test items need to be communicated)

|

4. Working Environment Requirements

Working environment: The working power supply requires mains power AC220V input,

power supply fluctuation range (170-260V), working environment temperature - 10 ℃ to 40 ℃,

working humidity of 10% ~ 90%, maximum power of 600W, which occurs only under the

condition of high test current.

Online service

Online service +86 13174506016

+86 13174506016