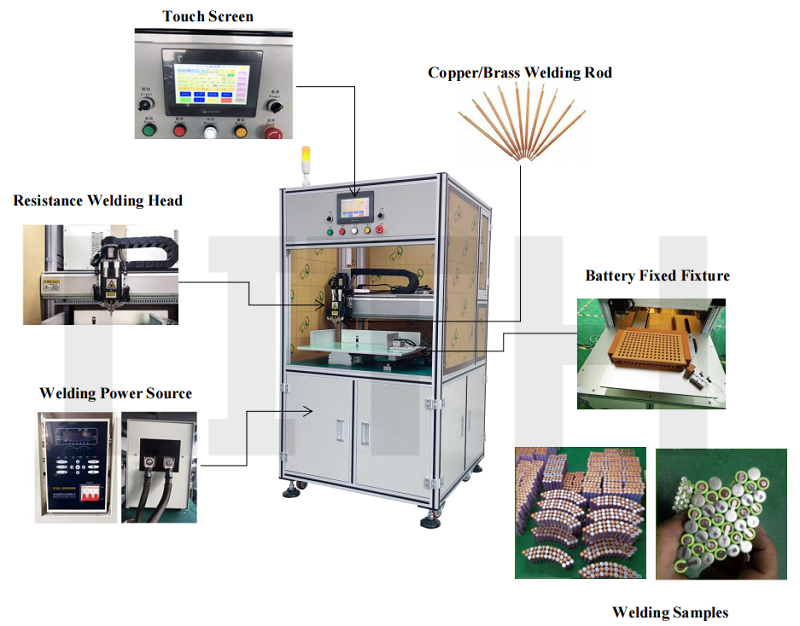

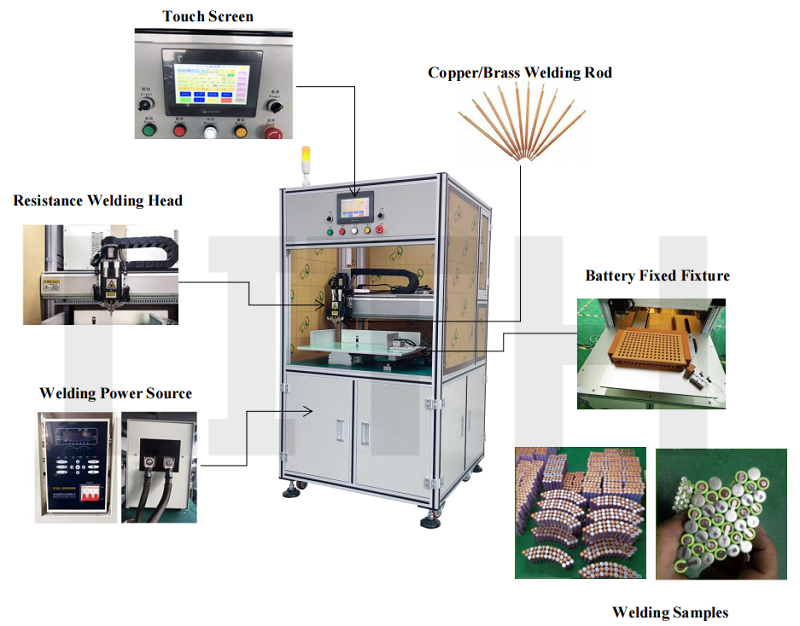

Automatic Single Side Spot Welding Machine With 5000A / 8000A Inverter DC Welding Power Supply / Transistor Welding Power Supply for Lithium Cylindrical Battery Pack Assembly

Introduction:

1.Designed for 18650,26650,21700, 32650 etc battery pack welding, like E-bike, scooter and electro mobile battery pack welding.

2.5000A invert spot welding power supply, high quality welding effect. Optional 8000A invert spot welding power supply and 8000A Transistor welding power supply.

3. Servo motor driving, fast, stable welding.

4. Programmable welding process, can produce any shape battery pack.

5. Real-time welding effect monitoring warning for NG welding spot.

Application:

Photovoltaic, power battery, NiMH lithium battery and other batteries are connected with nickel alloy strip, aluminum nickel composite strip, wire and guide strip, household electrical parts and guide strip, hardware accessories, copper and silver products, stainless steel peripheral connection, bulb foot welding, electronic parts, all kinds of high and low conductive metal welding, etc.

Feature:

1) Induct the load voltage, control the voltage in the feedback mode, and realize high-quality welding.

2) Power on mode of pre heat and main heat: preheat before welding to ensure stable welding quality.

3) Keep the continuity of energy density, short welding time, reduce the deformation and discoloration of base metal. (the welding time is controlled in microseconds, and the mode of continuous output)

4) Easy to change from low current to high current, suitable for precision welding.

5) The upper and lower limits of current can be set to judge whether the welding quality is good or not, which is suitable for the welding automation platform.

6) The welding current will rise with the power on time to ensure the welding effect.

7) Stable control system

8) High configuration regulating device

9) High precision working procedure

10) High cost performance of products

Performance features:

1. Touch screen display, more convenient operation and clearer display

2. Three file programming modes, manual input, array, CAD drawing import, simple and fast response to various complex program editing

3. The welding head has the function of air cooling or water cooling, which can effectively reduce the influence of spot welding needle temperature on welding quality

4. It can store up to 99 groups of files, which is easy to call and does not need complicated process of line changing and machine adjusting

5. The spot welding program of a side and B side of fixture can be switched.

Technical Parameters:

|

Power Supply

|

AC 220V± 10% 50Hz

|

|

Electric Current

|

DC

|

|

Welding Mode

|

Inverter DC

|

|

Welding Current

|

5000A or 8000A optional

|

|

Power Form

|

Automatic

|

|

Y-axis Travel

|

400mm (can be customized)

|

|

X-axis Travel

|

500mm (can be customized)

|

|

Spot Welding Speed

|

0.35s/point; 2800pcs / hour

|

|

Fast Speed of Motor Drive

|

1000mm/s

|

|

Number of Cores Loaded

|

X direction: 26

Y direction: 26

(standard:18650 cell)

|

|

Number of file groups that can be stored

|

99 group

|

|

Operating System

|

Embedded system + man machine interface

|

|

Transmission mode

|

Stepping + imported precision linear guide rail, optional servo + screw rod)

|

|

Equipment air pressure

|

0.4-0.7Mpa

|

|

Weight

|

200kg

|

|

Size

|

900*900*1650mm

|

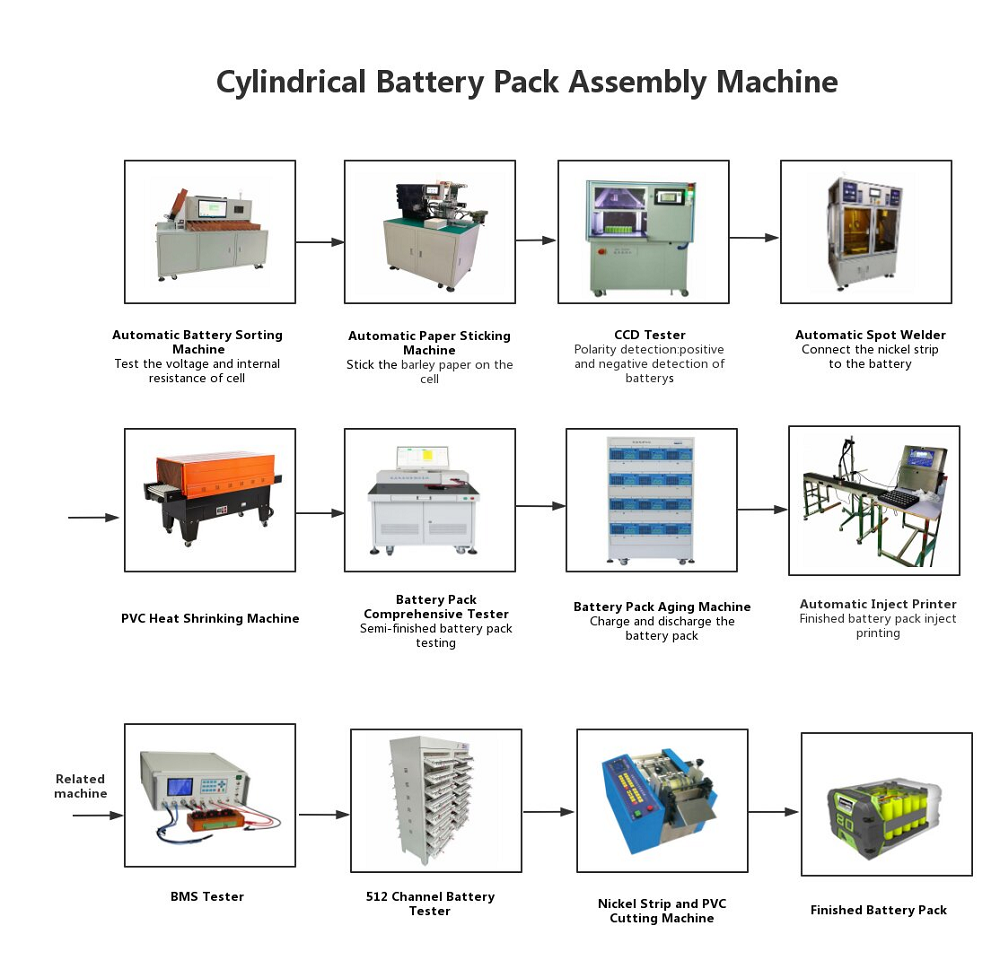

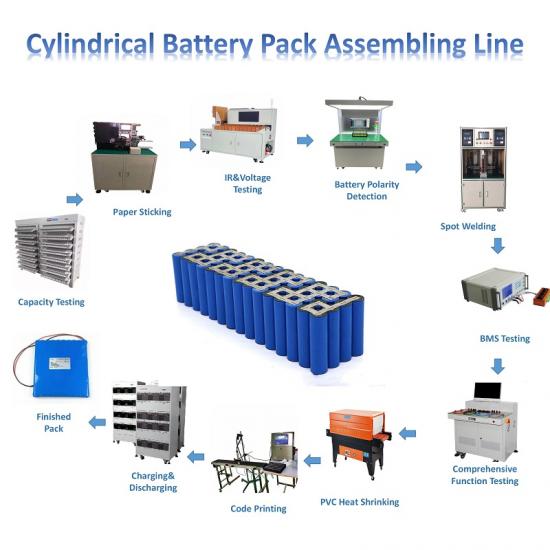

Select manual or automatic spot welding machine?

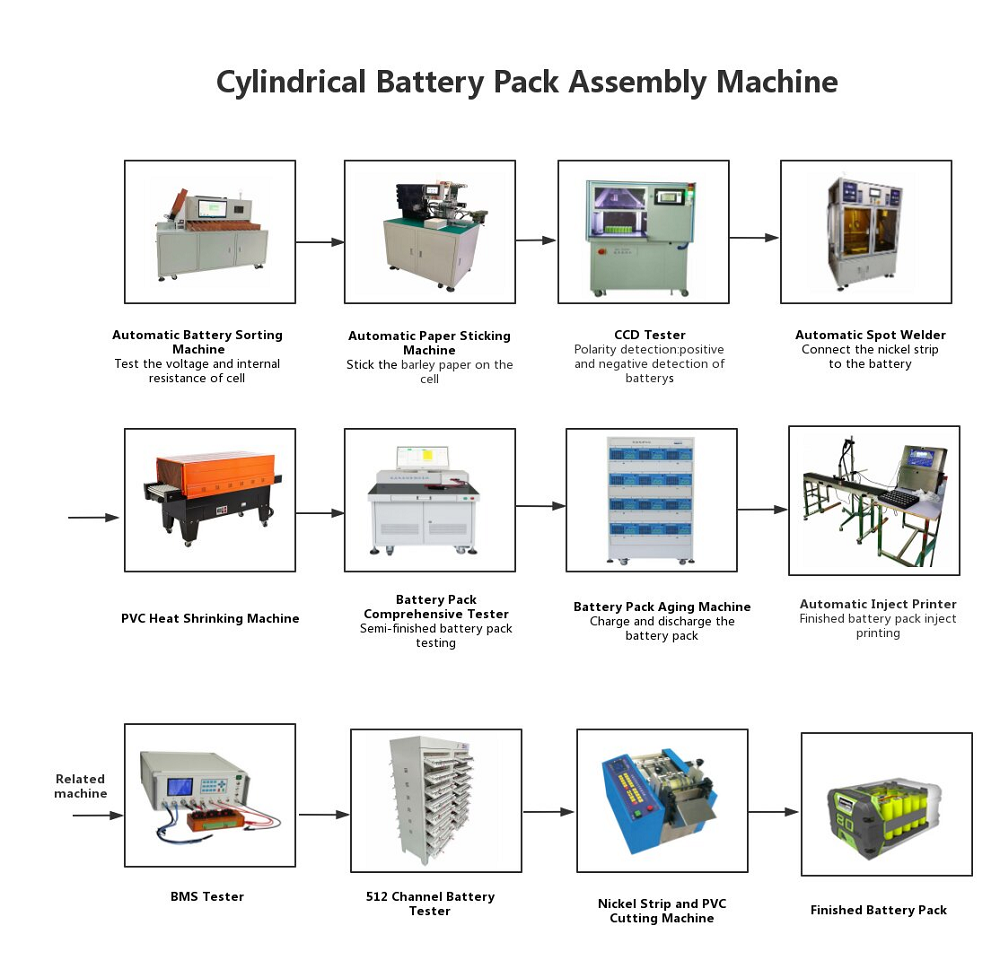

This equipment is mainly used for welding the battery and nickel strip in the cylindrical battery assembly. If the output is relatively high, you want to use an automatic spot welder instead of a manual one, automatic single side spot welder and double sided spot welder can be choosen, The efficiency of double-sided spot welding machine is higher than that of single-sided spot welding machine. The welding pulse width is adjustable, the welding spatter is small, and the welding spot is not discolored. It has the function of two-stage current detection and comparison, sound and light alarm for abnormal current, effectively preventing the occurrence of false welding and false welding. It has the function of fault self diagnosis, displaying the corresponding fault points and facilitating maintenance.

Online service

Online service +86 13174506016

+86 13174506016