Semi-Auto Lithium Cylindrical Battery Pack Assembling Plant

Introduction

The new energy lithium battery pack assembly line is widely used in power tools, smart homes, electric vehicles, photovoltaic energy storage, intelligent lighting, mobile power, small appliances and new energy vehicles. In just a few years, the application scope of lithium ion battery pack has expanded from the scope of our ordinary industry. It is not only used for laptops, portable CDs and other digital products. We usually use electric bicycles to travel, and some of them have also started to use lithium ion battery packs. In some shopping malls and field operations, the standby power supply is also a lithium ion battery pack, while the power supply of some aircraft is also a lithium ion battery pack. It can be seen that the application scale of lithium ion battery pack is increasingly extensive.

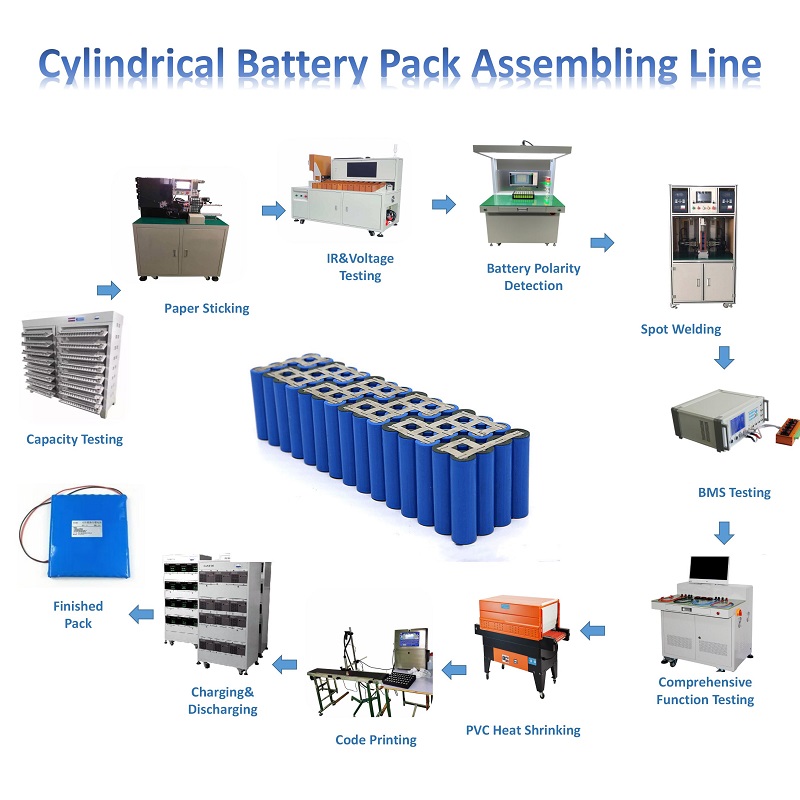

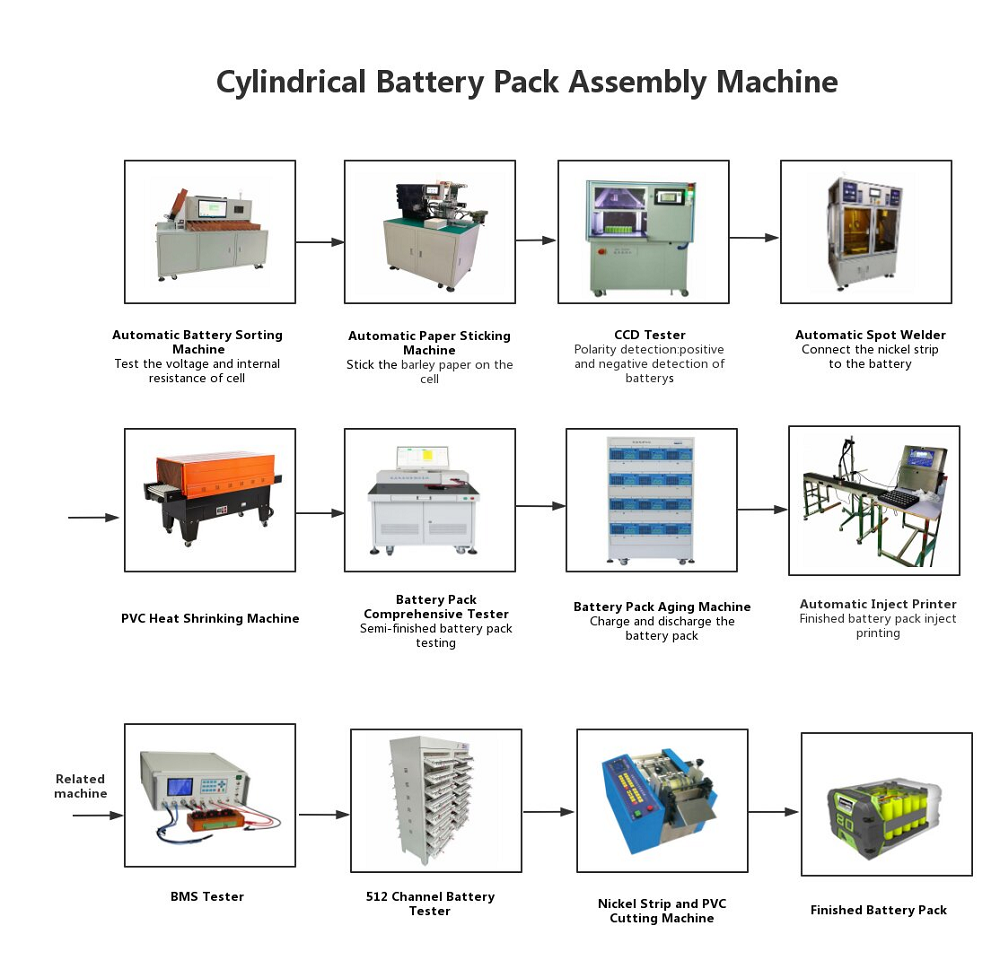

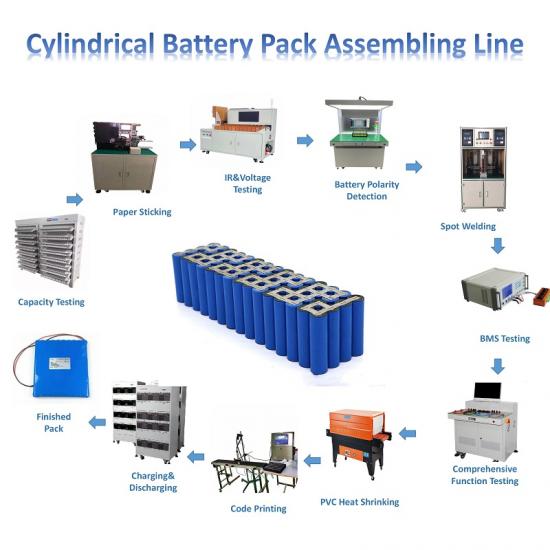

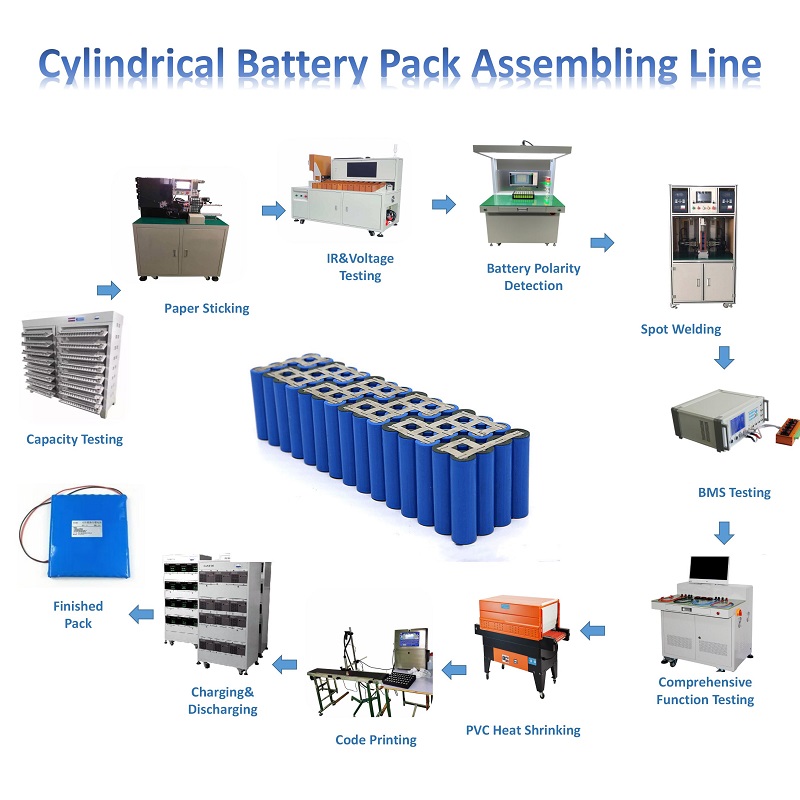

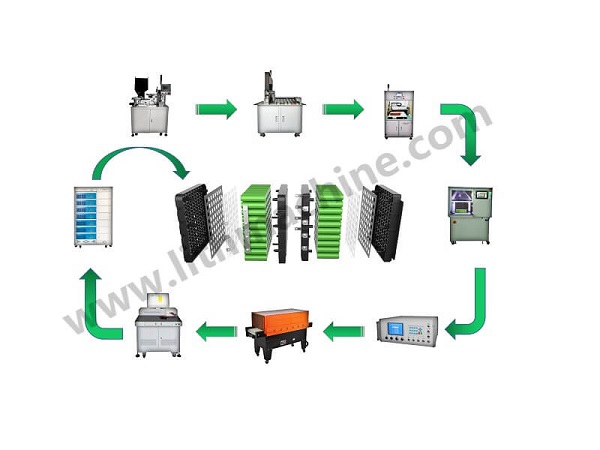

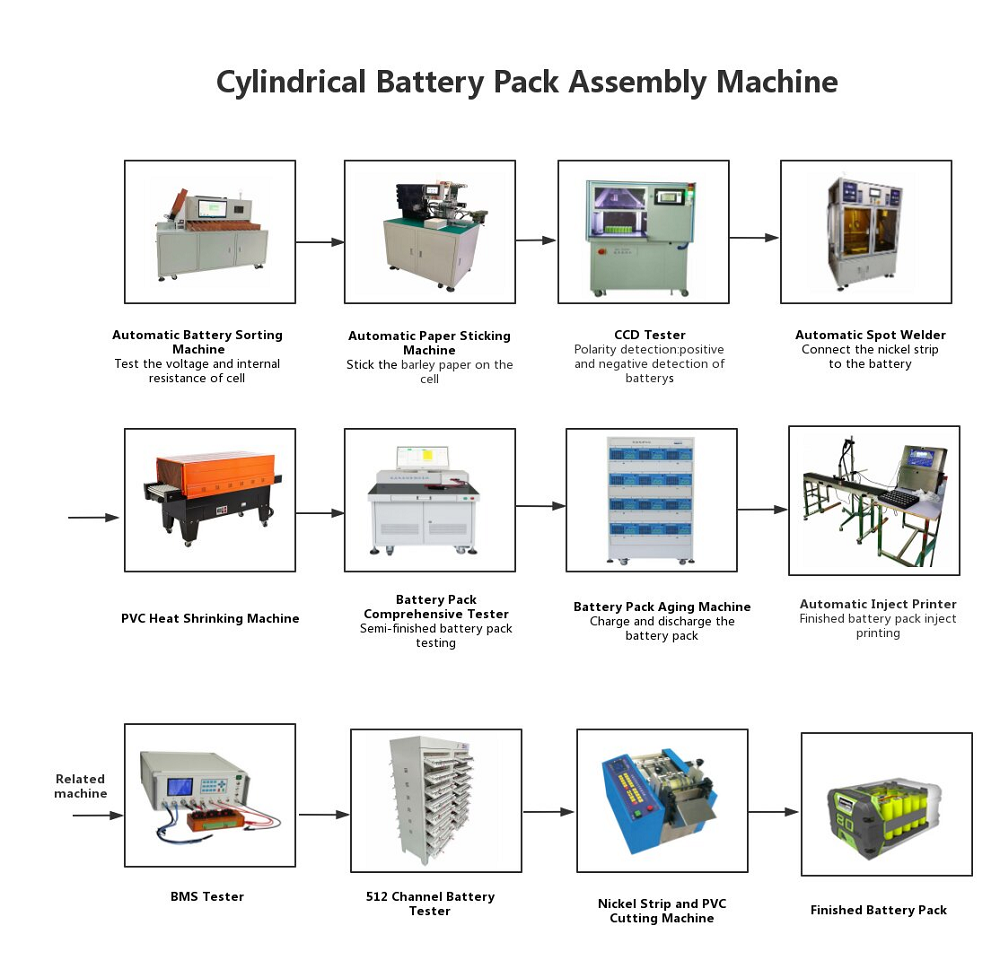

Important process:

1. Detection of single cell:

Battery Tester is mainly used to detect whether the parameters such as cell capacity, magnification and cycle times meet the use requirements. Test each single cell’s capacity to make sure the battery has good quality.

Because different batches of batteries made by many battery manufacturers will have inconsistent capacity, internal resistance, open circuit voltage and charge discharge performance. The production of battery pack needs to ensure the consistency of battery.

2.Paper sticking

Battery Paper Sticker:

The positive electrode of the battery is pasted with insulating highland barley paper to protect the battery. Ensure that the battery will not be short circuited during assembly, the pasting machine which can save labor cost. If the budget is limited, you can also select manual pasting in this step.

3.IR&Voltage Sorting

The lithium battery sorter can test the internal resistance and voltage of single cell. Currectly we offer cylindrical cell sorter with 5 channel and 11 channel optional for 18650/21700/26650/32650/32700 cells sorting. 11 channel sorter can equip with computer that has data record function. For IR teseter, HK 3561 tester and HIOKI 3561 tester can be selected according to your needs and budget. It can be set to multiple gears through the upper and lower limits of internal resistance. The resistance is adjustable, and the adjustment mode is diversified and fast. It is equipped with imported voltage internal resistance tester, integrated PC, high-end drive, all electric motor configuration; Process detection signal comprehensive and bid farewell to a single industrial machine.

4.Battery Polarity Detection

CCD Tester:

CCD visual inspection tester can detect whether the positive and negative polarity of the battery is correctly placed before spot welding, which is very important. If the machine is not used for detection, it is also necessary to ensure that the polarity is placed correctly. The device has higher efficiency and accuracy in detecting whether the batteries are correctly placed in series-parallel positive and negative electrodes and in detecting products with defects in spot welding.

5.Spot Welding

Spot Welding Machine:

This equipment is mainly used for welding the battery and nickel strip in the cylindrical battery assembly. If the output is relatively high, you want to use an automatic spot welder instead of a manual one, automatic single side spot welder and double sided spot welder can be choosen, The efficiency of double-sided spot welding machine is higher than that of single-sided spot welding machine. The welding pulse width is adjustable, the welding spatter is small, and the welding spot is not discolored. It has the function of two-stage current detection and comparison, sound and light alarm for abnormal current, effectively preventing the occurrence of false welding and false welding. It has the function of fault self diagnosis, displaying the corresponding fault points and facilitating maintenance.

6. BMS Testing

BMS Tester:

The multifunctional protection board tester is mainly used to test whether the functional indexes of the power battery protection board are within the parameter range, so as to provide a set of testing standards for the staff. We can offer 1-24 series BMS tester, 1-32 series, the max Over discharge protection current up to 120A/150A/200A/300A with or without PC model optional.

7.Comprehensive Function Testing

Battery Pack Comprehensive Function Tester:

The main test items include: open circuit voltage, AC internal resistance, discharge test, discharge over-current test, short circuit protection test, charging test and charging protection test.

8.PVC Heat Shrinking

PVC Heat Shrinking Machine is used for shriking the PVC of battery pack.

9.Code Printing

Ink Jet Printer :

It Is For Code Printing On The Battery Pack.

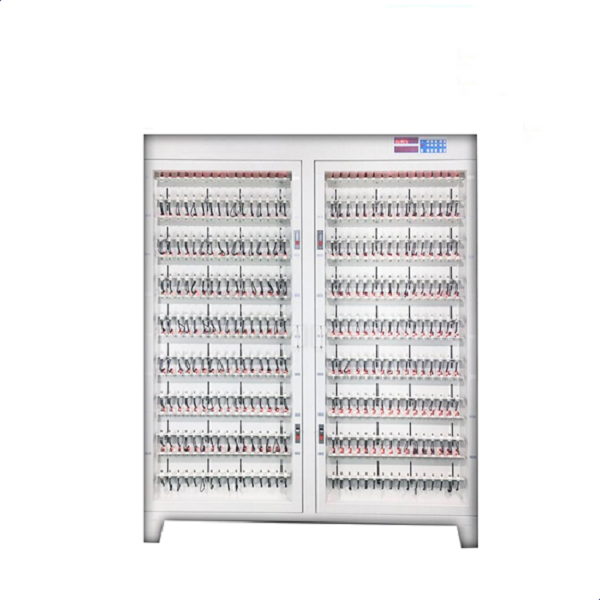

10. Charging&Discharging

Battery Pack Aging Machine:

The aging cabinet is mainly used for testing the charging and discharging cycle of finished lithium batteries.30V 10A charge 20A discharge/ 70V 5A 10A/ 70V 10A 20A/ 85V 10A 20A/ 100V 10A 20A/ 100V 20A 40A optional. Which aging machine is used depends on your battery pack capacity.

Online service

Online service +86 13174506016

+86 13174506016