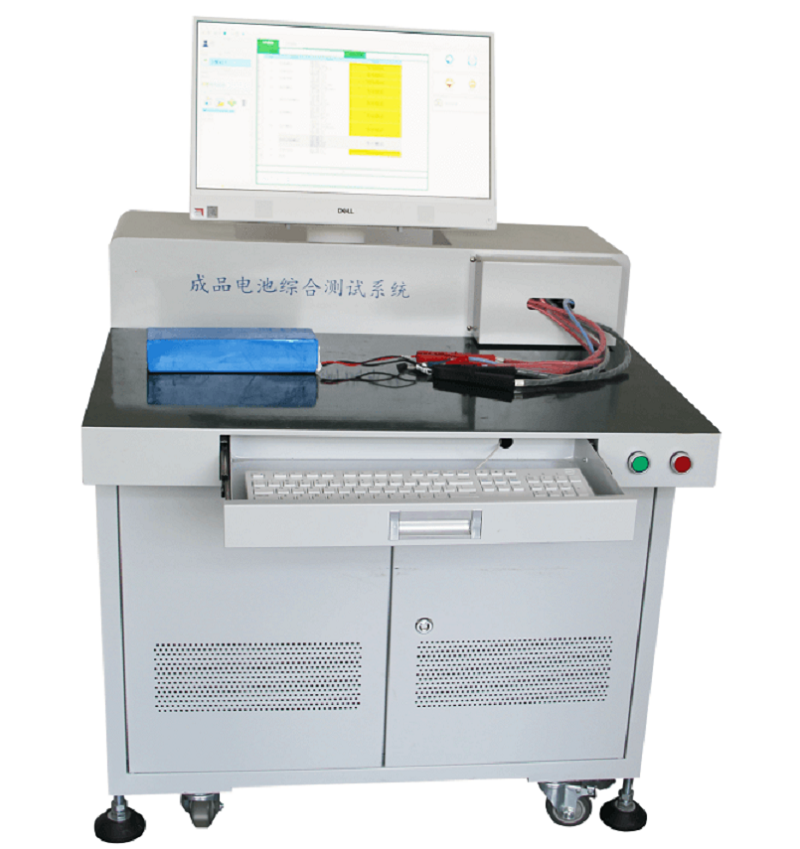

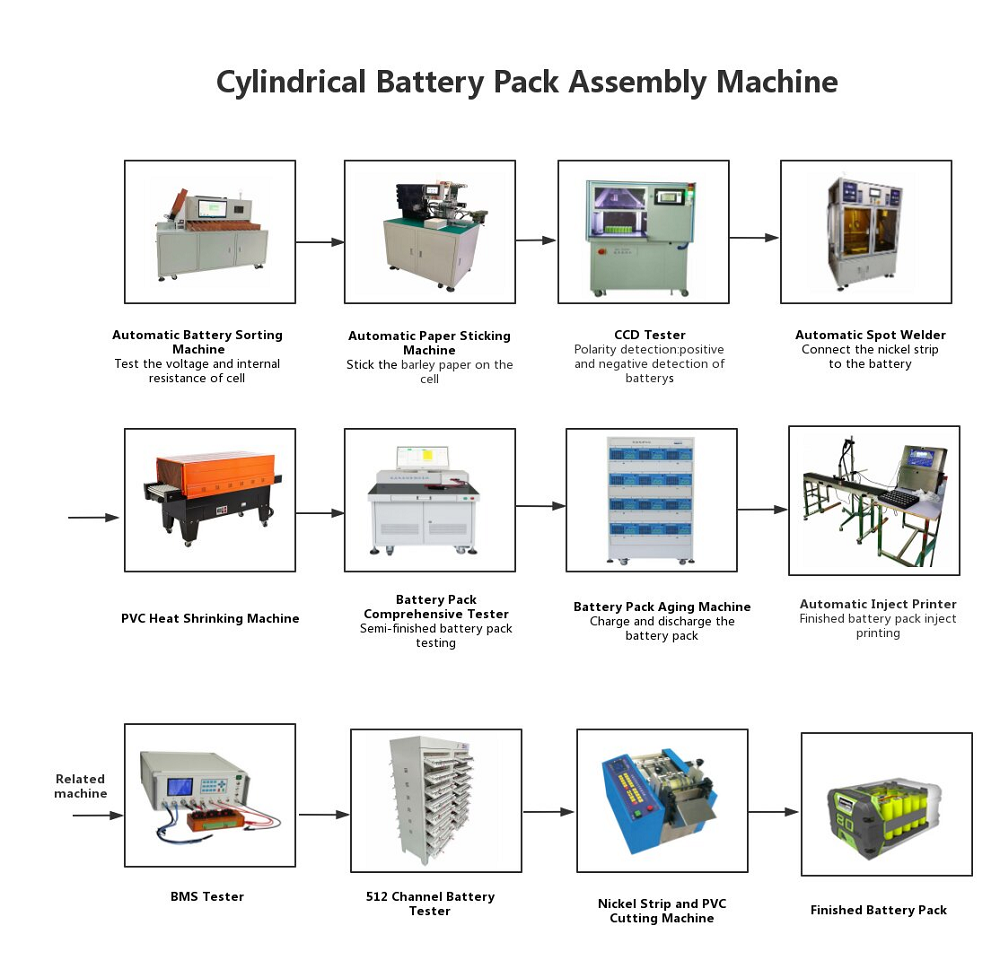

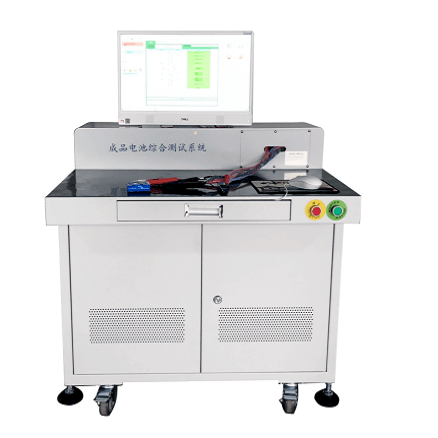

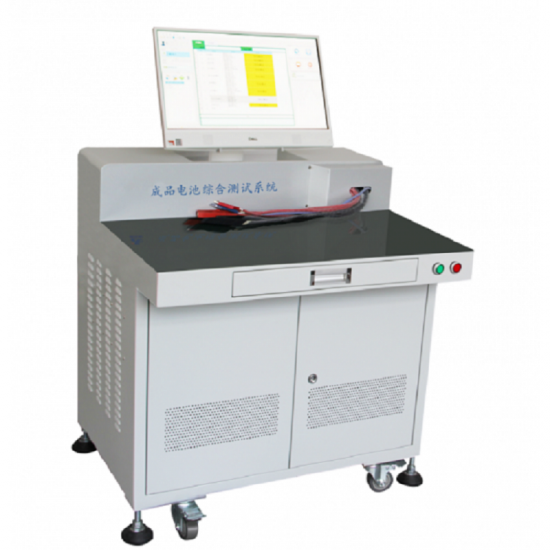

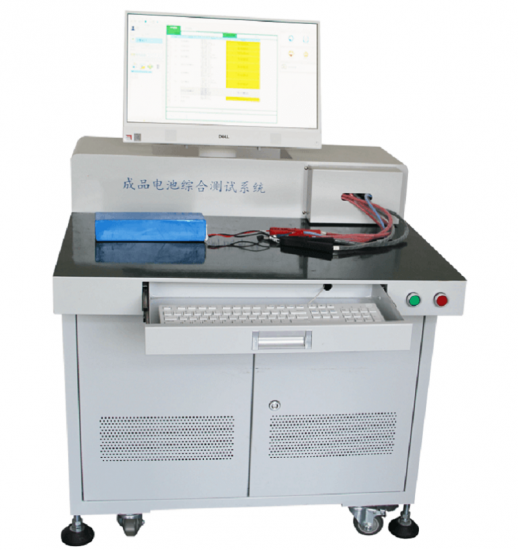

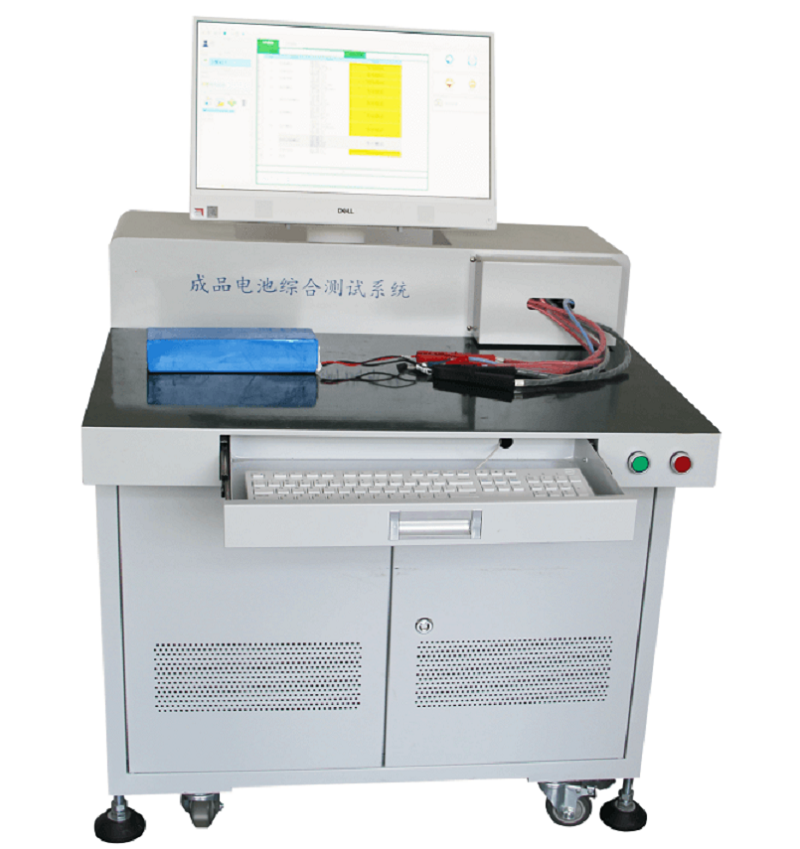

100V 120A 18650 21700 26650 Lithium Battery Pack Comprehensive Tester for Battery Pack Semi-finished Performance Test

Feature:

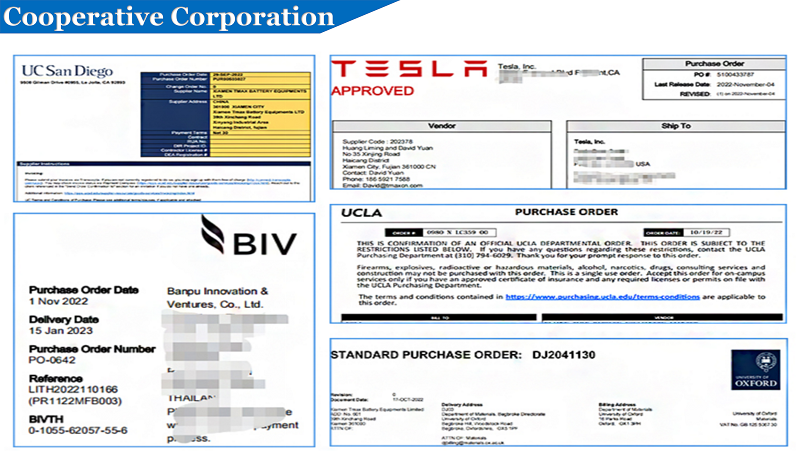

The comprehensive test equipment for finished battery is a fast and accurate device for testing the performance of finished battery. The main test items include: open circuit voltage, AC internal resistance, discharge test, discharge over-current test, short circuit protection test, charging test and charging protection test. The system adopts 32-bit ARM processor and 16 bit AD converter for voltage and current. Compared with similar equipment, it has faster test speed, higher test accuracy and supports simultaneous operation of multiple equipment. It is widely used in the production, scientific research and experimental test of power batteries such as automotive electronics, aerospace, ships, solar energy storage, electric bicycles, electric motorcycles, backup power batteries, communication power supplies, etc.Tmax is also the manufacturer and solution provider of battery pack machine.

Test items:

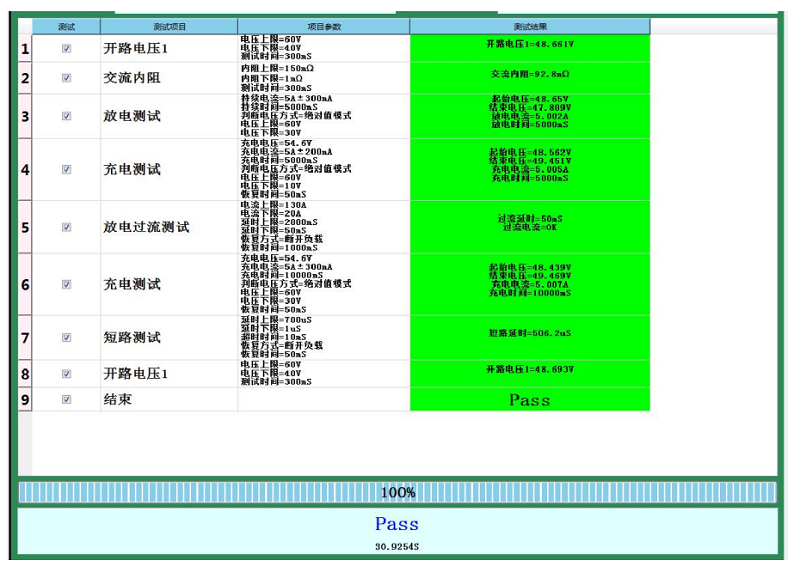

1. Open circuit voltage: test the voltage at both ends of the positive and negative poles of the battery.

2. AC internal resistance: test the resistance at both ends of the battery discharge circuit.

3. Discharge test: test the continuous carrying capacity of the battery, and check the voltage drop of the battery for a certain period of continuous discharge.

4. Discharge over-current test: test the high current discharge protection function of the battery, and the high current discharge of the battery triggers the discharge over-current protection function of the battery protection board.

5. Short circuit protection: test the battery positive and negative short circuit battery cut-off protection time (microsecond level).

6. Charging test: test the battery's continuous charging function and whether the battery's charging function is good.

7. Charging over-current test: test the high current charging protection function of the battery, and the high current charging of the battery triggers the charging current protection function of the battery protection board.

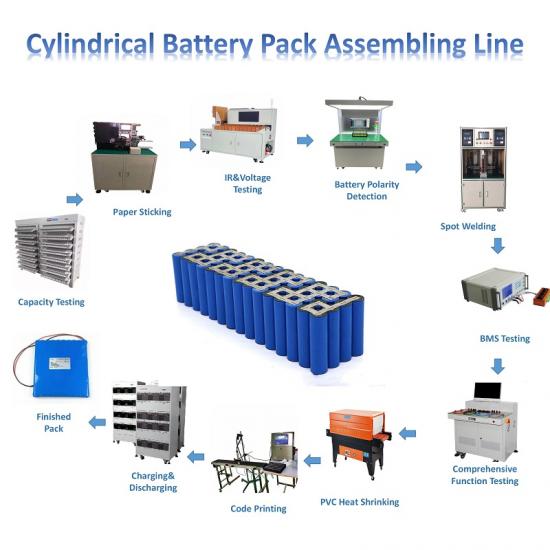

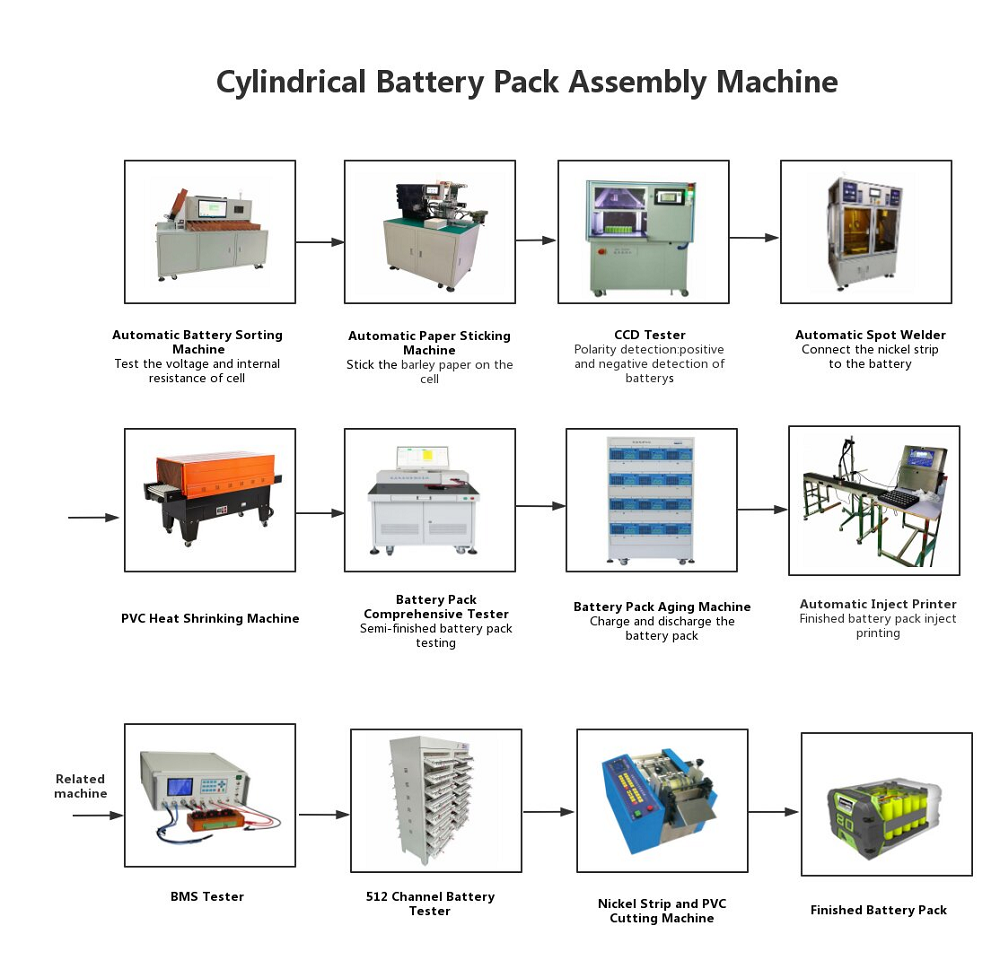

We provide a full series of Energy Storage Battery Assembly for different customers.

Main Features:

1. The continuous output power of the equipment is 2KW.

2. The continuous load power of the equipment is 12KW.

3. The maximum test voltage is 100V. (can be customized according to requirements)

4. Maximum charging current (20A), discharge current (120A). (can be customized according to requirements)

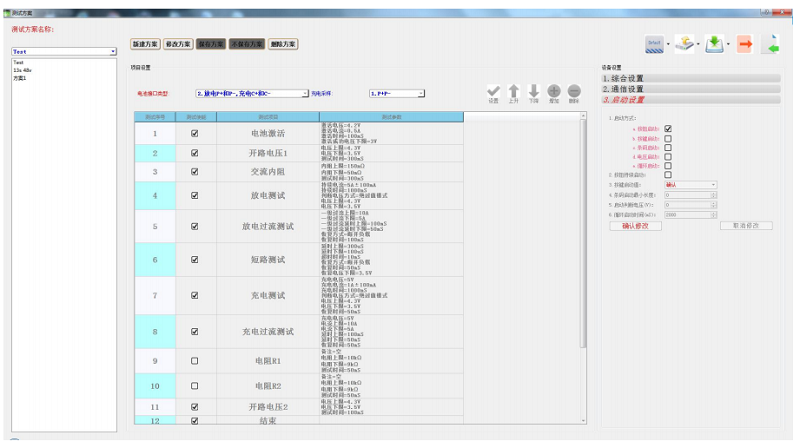

5. Programmable control of test items.

6. Friendly human-computer interface.

7. Support one upper computer software to control 8 devices.

8. The device supports serial port, network and upper computer communication.

9. Test records can be saved to database (SQL) or file (Excel).

10. Support the export and import function of test project.

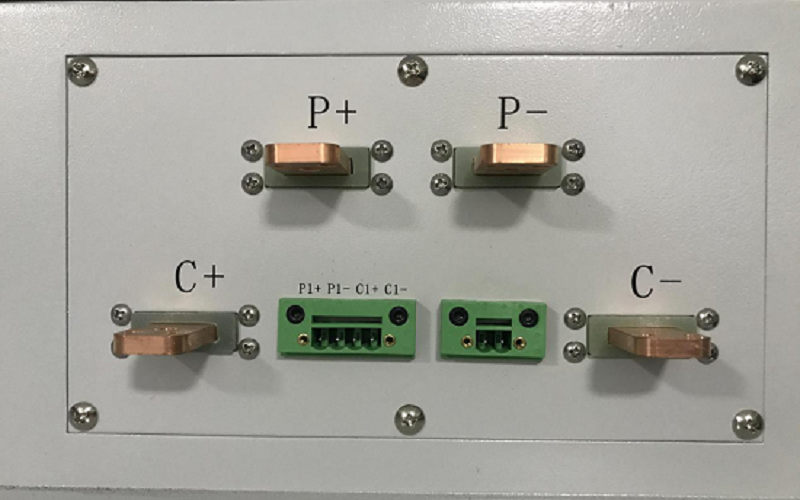

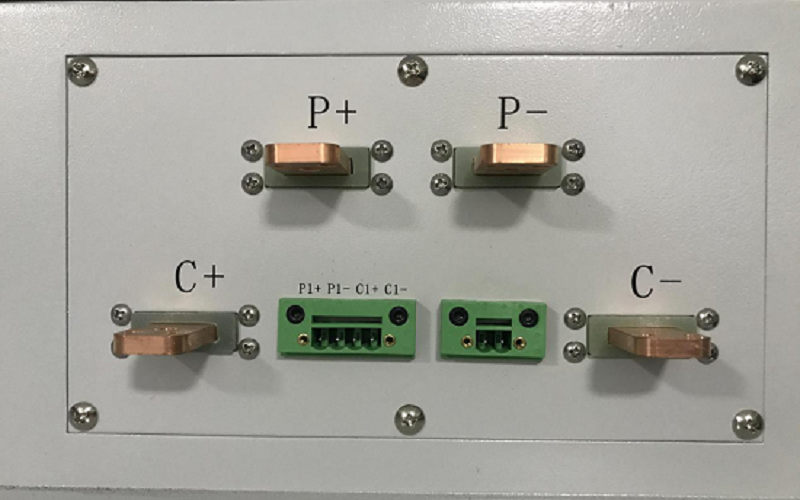

11. The equipment supports the same port and split port batteries for charging and discharging.

12. The device supports the function of charging and activating the battery.

13. Consistency evaluation test of battery cell.

14. Internal resistance test of battery pack.

15. Battery load on load test.

16. Battery pack high current protection test.

17. Battery authenticity short circuit protection test.

18. Battery pack continuous charge test.

19. Battery pack high current charging protection test.

20. Equipment input voltage AC220V / 50Hz. (input line must be grounded)

The input housing of the equipment is well grounded.

|

Model

|

BTS100-20-120

|

|

purpose

|

Used for testing semi-finished products and finished products of battery packs below 100V

|

|

basic function

|

Open circuit voltage test

|

|

AC internal resistance test

|

|

ID Resistance test

|

|

NTC Resistance test

|

|

Charging performance test

|

Battery PACK continuous charging function to verify whether the charging is normal

|

|

Battery PACK charging overcurrent protection function test

|

|

Discharge performance test

|

Battery PACK Continuous load capacity, continuous discharge, check voltage drop

|

|

Battery PACK Discharge overcurrent protection function test

|

|

Short circuit protection test

|

Test the battery positive and negative short circuit battery cut-off protection time (subtle level)

|

|

Equipment protection function

|

Software protection function: power failure data protection

|

|

Hardware protection: power failure protection, short circuit protection, battery reverse connection and wrong connection protection

|

Equipment parameter description

|

Test class

|

Test items

|

Measuring range

|

Resolving power

|

|

Open circuit voltage

|

Open circuit voltage 1

|

10-100V

|

±2mV

|

|

Open circuit voltage 2

|

10-100V

|

±2mV

|

|

Internal impedance

|

AC internal resistance test

|

0-1000mΩ

|

±1mΩ

|

|

Discharge test

|

Starting voltage

|

0-100V

|

±2mV

|

|

End voltage

|

0-100V

|

±2mV

|

|

discharge current

|

0.1-60A

|

±1mA

|

|

Discharge time

|

0-60S

|

±1mS

|

|

Discharge overcurrent test

|

Over discharge current

|

4-120A

|

±1mA

|

|

overcurrent delay

|

0-20S

|

±1mS

|

|

Short circuit protection

|

Short circuit protection delay

|

0-9999uS

|

±1uS

|

|

Charging test

|

Starting voltage

|

10-100V

|

±2mV

|

|

End voltage

|

10-100V

|

±2mV

|

|

Charging current

|

0.1A-20A

|

±1mA

|

|

Charging time

|

0-60S

|

±1mS

|

|

Charging protection test

|

Charging overcurrent

|

4-20A

|

±1mA

|

|

Charging delay

|

0-20S

|

±0.1mS

|

|

Resistance R1/R2

|

NTC、ID

|

0-1000KΩ

|

±0.1KΩ

|

|

Sustainable output power

|

2KW

|

|

Sustainable load power

|

6KW

|

|

Online mode

|

serial communication

(RS232,It can be used online by multiple computers)

|

|

Test data

|

The generated data table is automatically saved and can be exported to excel

|

|

Barcode management

|

Support bar code startup and binding test data

|

|

Free software upgrade service

|

Upgrade for free for life until the hardware is incompatible

|

|

Heat dissipation

|

Rely on ventilation system and forced air cooling

|

|

Chassis size

|

1000*700*1300mm(W*D*H )

|

|

Weight

|

140KG

|

|

Channel

|

1

|

|

Equipment accessories

|

Computer, test pen line, user manual, upper computer software, etc

|

Range of Application:

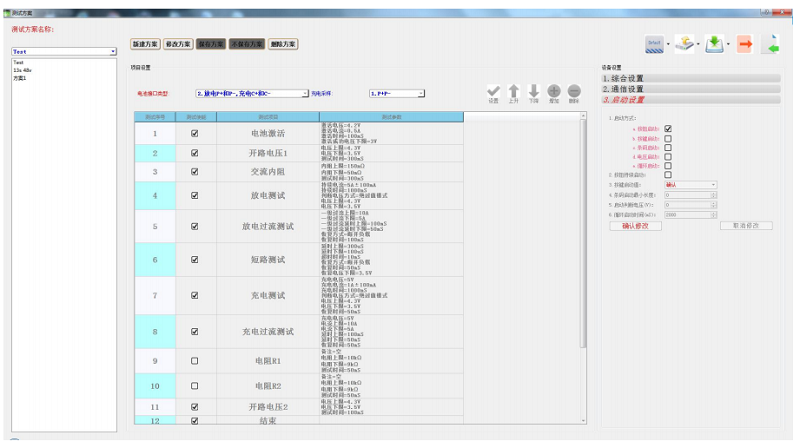

Scheme setting interface(Can be converted to English interface)

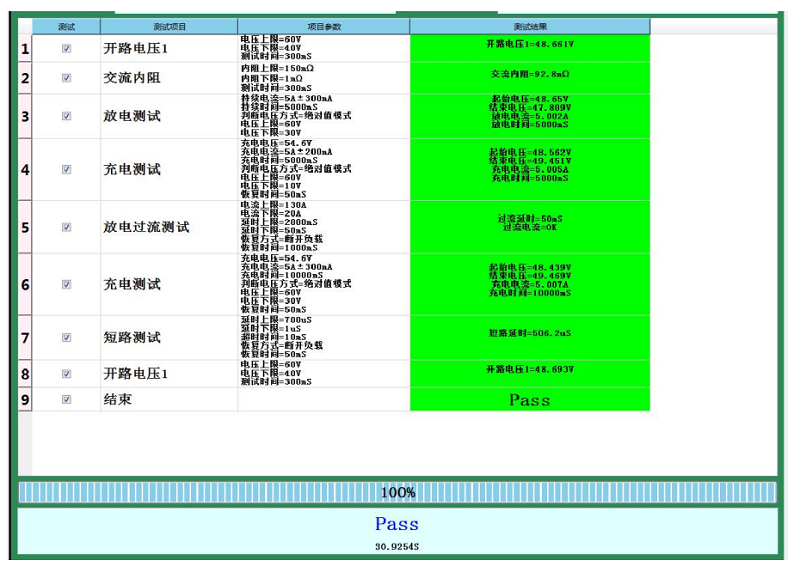

Test result interface(Can be converted to English interface)

Online service

Online service +86 13174506016

+86 13174506016