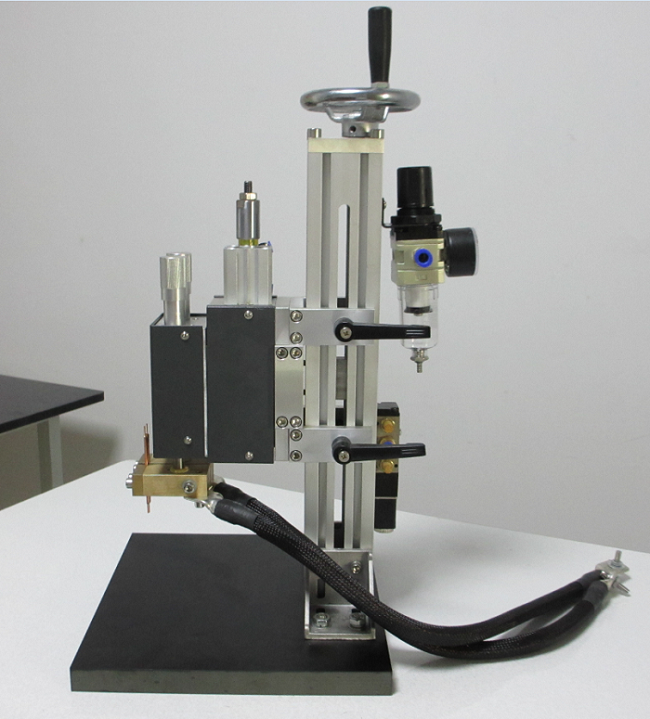

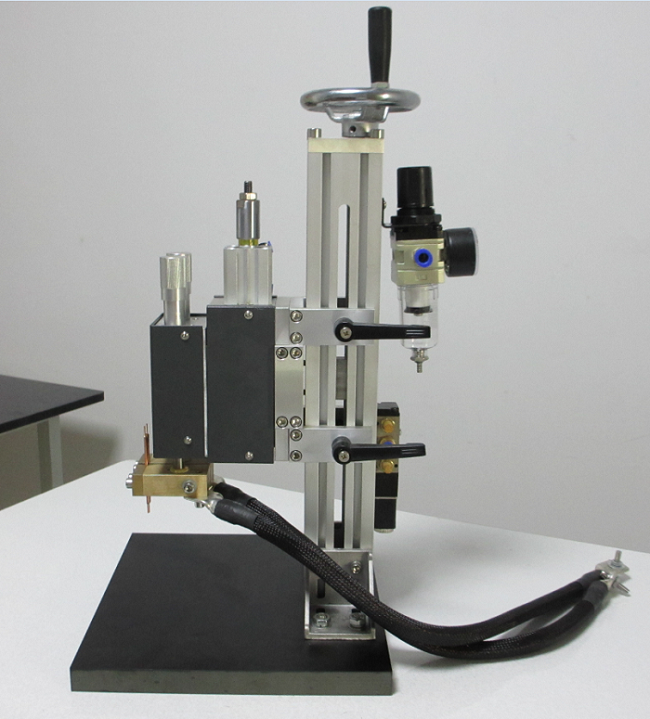

18650 Desk-Top Double Pulse Manual Spot Welding Machine For Battery Electrode Nickel Tabs Welding

Introduction and Features:

This LITH-PS300 Spot welding machine mainly used for 18650 battery pack tab welding, it can weld Nickel tab thickness from 0.05-0.20mm. You can also choose our other model according to your tab Thickness.

LITH-PS series battery assembly welding power source adopts Japan the most advanced welding technology, is the present domestic advanced level of high performance precision resistance welding machine, designed for the production of high-end mobile phone batteries, power batteries, digital batteries, nickel metal hydride, nickel cadmium battery, such as needed to design, also can welding parts, LED lights, electronic components, feet, capacitance, etc.

PS series precision resistance welding power source is the IGBT inverter technology, microcomputer control technology and modern power electronic technology development of a new type of power supply. Time control millisecond precision, control response and control precision is greatly increased; Significantly improve welding technology; Advanced technology and equipment has advantages of small, energy efficient and a series of; Microcontroller (MCU) and the using of electronic technology makes the equipment with outstanding features of modern equipment, including digital control, monitoring, fault diagnosis and protection, data transmission, etc., equipment is fully functional, flexible, convenient, adaptation of wide.

The main technical characteristics:

* high speed and high precision (MCU) microprocessor control, provide highly stable repeat welding.

* high speed welding: quick start and high-speed switch polarity to reduce the temperature effect so that the welding surface is clean and beautiful.

* polarity switch: inhibition of asymmetric effect for uniform two-point welding strength and prolong the service life of the electrode.

* welding response speed.

* blu-ray 19264 LCD screen display, graphical display of the current work status, friendly interface, welding pulse graphics functions improve the ease of debugging observation.

* double pulse reducing welding spatter, improve the welding quality.

* 2 different kinds of welding methods (1) the average spot welding; (2) continuous welding.

* internal welding counter, can do all its solder joints.

* block data storage using EEPROM, no battery life issues, to the use of welding procedure every time you boot.

* compatible with welding pressure switch welding head and without welding welding head pressure switch.

* preloading time, pressure maintaining time continuous adjustable from 0 to 2.55 seconds.

* pressure discharge switch can use photoelectric switch, non-contact, durabl.

Specifications:

|

project

|

PS300

|

|

power

|

18KVA

|

|

Welding current

|

3500A

|

|

The welding output voltage

|

5.5V

|

|

Welding pulse

|

Double pulse

|

|

puls1

|

0-100.0%

|

|

puls2

|

0-100.0%

|

|

Welding mode

|

common/continuous

|

|

The input voltage

|

220V/50/60Hz

|

|

Air pressure

|

0.2-0.4MPA

|

|

The weight of the

|

35KG

|

|

size

|

400mm X 220mm X h360mm

|

Online service

Online service +86 13174506016

+86 13174506016