Laboratory Pouch Cell Heat Sealer Machine For Battery Top Side Crimping

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-YFPayment:

Credit Card, Paypal, T/T , Western Union, LCLead Time:

5 days200mm-400mm Customized Lab Pouch Cell Vacuum Sealing Machine After Electrolyte Filling

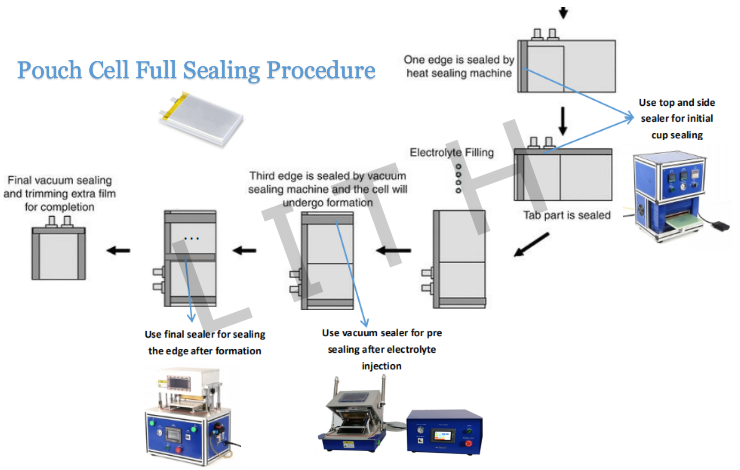

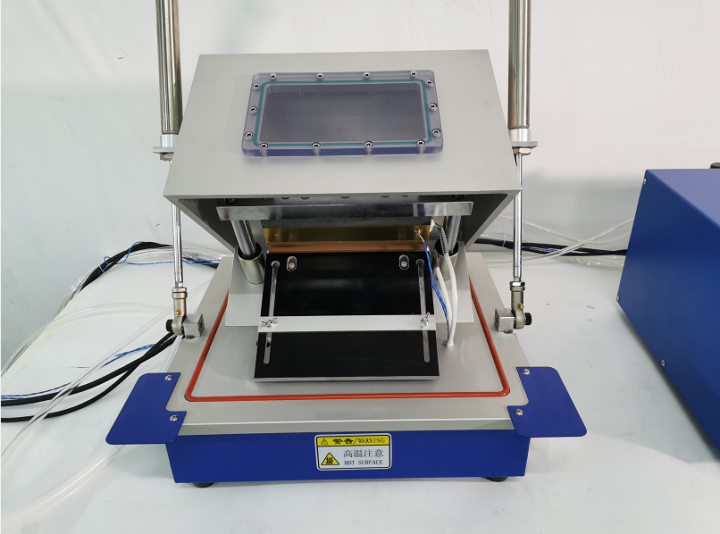

Introduction

LITH-YF vacuum sealer is applicablt for pouch cell vacuum sealing after electrolyte filling and standing; the machine can automatically complete vacuum thermal sealing of Al-plastic film by precisely controlling the main vacuum pumping box and pneumatic hot sealing components.

Main features

* the sealing head is made of copper material, which has good heat transfer effect, saves power consumption, improves work efficiency and saves energy compared with similar products;

*The pressure of upper and lower heads can be adjusted by pressure regulating valve to meet the requirements of different process parameters;

*The upper and lower heads are driven by cylinder and guided by two linear guide sleeves, which can move up and down flexibly and guide accurately

*Ensure the requirement of parallelism after edge sealing;

*Through the perspective window, we can observe the changes in the cavity when working.

*The cover is driven by cylinder and guided by rotating guide sleeve, which can move up and down flexibly and guide accurately to ensure the sealing requirements of products.

*It can be used for batteries of different specifications, and the adjustment is simple and convenient.

*The main engine and control box are designed separately, so that the machine can work in glove box or on assembly line.

*Simple operation, beautiful appearance, small volume and light weight.

Specification

|

Chamber |

The chamber is made of aluminum alloy, which is corrosion resistant and has a firm structure; |

|

Vacuum degree |

The vacuum degree can be adjusted up to -95Kpa (the buyer shall provide the vacuum pump); |

|

Head temperature |

RT~250℃, temperature adjustable; |

|

Temperature control accuracy |

±2℃; |

|

Heat sealing pressure |

0~7Kg/cm2 adjustable; |

|

Heat sealing time |

0~99 seconds adjustable; |

|

Edge sealing width |

5±0.4mm (can be customized) |

|

Maximum edge sealing length |

200mm (can be customized as 300mm, 400mm, etc) |

|

Seal thickness range |

60~300um |

|

Seal thickness accuracy (mm) |

Sealing thickness difference between any two points<15um |

|

Air consumption |

About 0.2L compressed gas per seal once. |

|

Working speed of air compressor |

≥180 times/h |

|

power |

Using 300w heating tube, the power consumption when heating is about 0.6KW. |

|

Power Supply |

220V/50Hz; |

|

Compressed air source |

0.5~0.8Mpa; When used in the glove box, the cylinder power source must use the same working gas used in the glove box; |

|

Working chamber |

470mm*485mm*435mm; |

|

Control box |

420mm*325mm*225mm |

|

Equipment weight |

About 50Kg |

Online service

Online service +86 13174506016

+86 13174506016 Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8613174506016

+8613174506016