200mm-400mm Customized Lab Pouch Cell Vacuum Sealing Machine After Electrolyte Filling

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-SFZ200Payment:

Credit Card, Paypal, T/T , Western Union, LCLead Time:

5 daysLaboratory Pouch Cell Heat Sealer Machine For Battery Top Side Crimping

Features

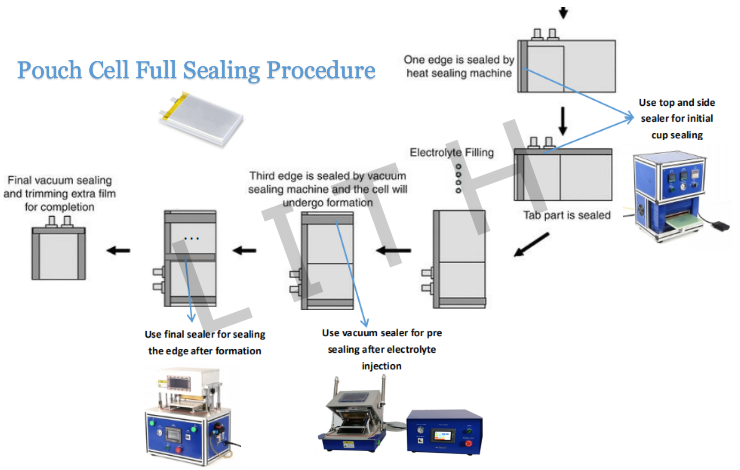

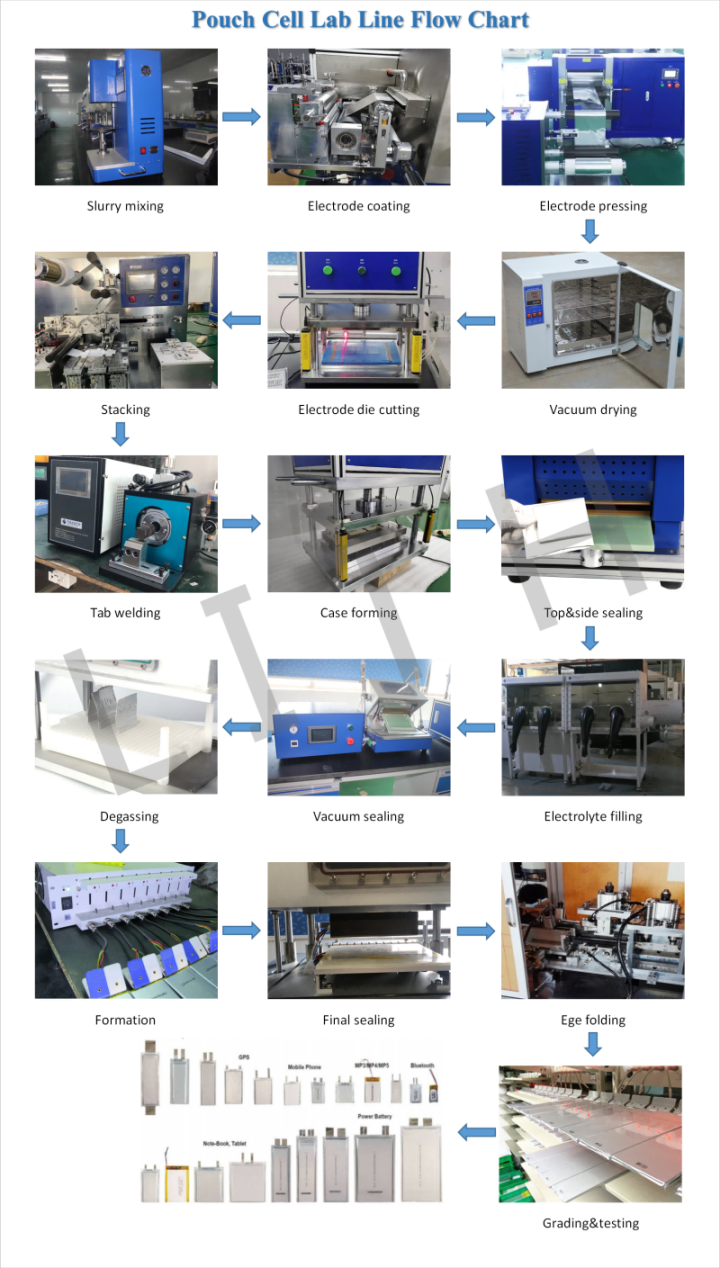

LITH-SFZ200 is a compact heating sealer for sealing aluminum-laminated films during pouch cell (polymer Li-Ion cell) case preparation. It can prepare the pouch cell for the injection of an electrolyte by sealing the side and top of the pouch cell with the tab.

Working principle

It is transmitted to the head (copper) through the resistance heating tube, and acts on the sealing material (aluminum laminated film) of lithium battery by using the heat conduction effect. Under a certain pressure, it is heated to become soft and close to the melting state to complete the compression fusion joint. The top seal and side seal can be realized without changing the mold.

Main features

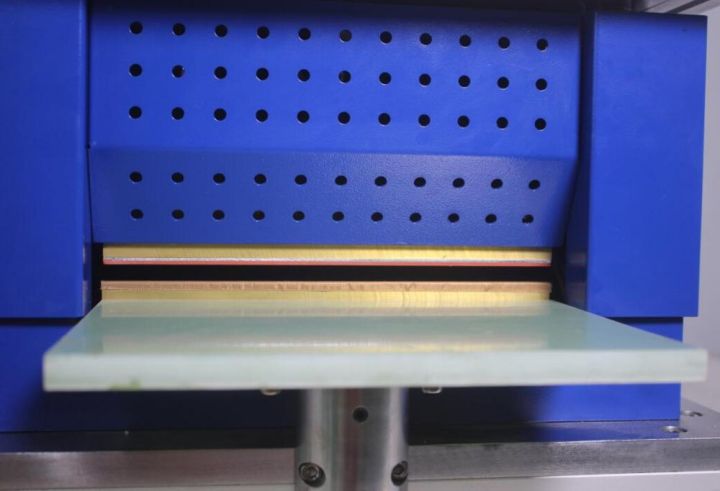

1. Unique safety protection and anti scalding design, the temperature of upper and lower ironing head can be adjusted by the button on the temperature controller panel;

2. The head is made of copper material, which has good heat transfer effect, saves power consumption, improves working efficiency and saves energy compared with similar products;

3. The pressure of upper and lower heads can be adjusted by pressure regulating valve to meet the requirements of different process parameters;

4. The upper and lower heads are driven by air cylinder and guided by two linear guide sleeves, which can move up and down flexibly and guide accurately, so as to ensure the parallelism requirements of products after edge sealing;

5. It can be used for batteries of different specifications, and the adjustment is simple and convenient, and there is no need to adjust and replace the head;

6. The frame made of aluminum profile has beautiful appearance; the sheet metal adopts solid geometry design, which is simple and beautiful;

7. Small size, smooth and even sealing mark and beautiful edge sealing appearance;

Specification

|

Maximum seal length |

200mm~400mm(can be customized) |

|

Seal width |

5mm±0.4(3~10mm can be customized) |

|

Side sealing thickness |

60~300um |

|

Thickness of top tab edge sealing |

200~700um |

|

Heat sealing temperature |

RT~250℃ adjustable |

|

Temperature accuracy |

±2℃。 |

|

Sealing time |

0-99s adjustable |

|

Seal thickness accuracy (mm) |

The thickness difference between any two points is less than 15um |

|

Safety device |

Equipped with protective device to prevent high temperature scald. |

|

Operation mode |

The equipment has the function of automatic and manual operation. |

|

Flexibility |

The equipment is easy to clean and replace the copper mold. |

|

compressed air |

5~8kg/cm2 |

|

Working speed of air compressor |

≥400 times/hour |

|

Power Supply |

AC220V/110V, 50/60Hz |

|

Power |

0.5KW |

|

Dimensions |

L430x W330x H480mm |

|

Equipment weight |

35Kg |

Online service

Online service +86 13174506016

+86 13174506016 Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8613174506016

+8613174506016