5V 3A 512 Channel Charge And Discharge Testing Equipment for Lithium Cylindrical Battery

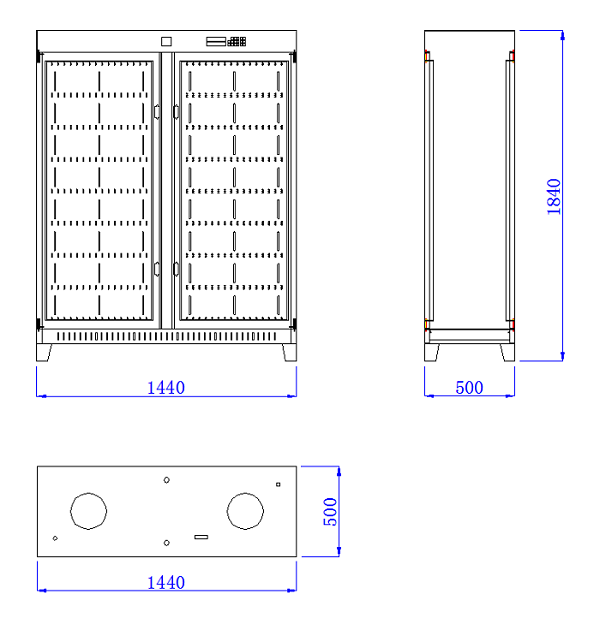

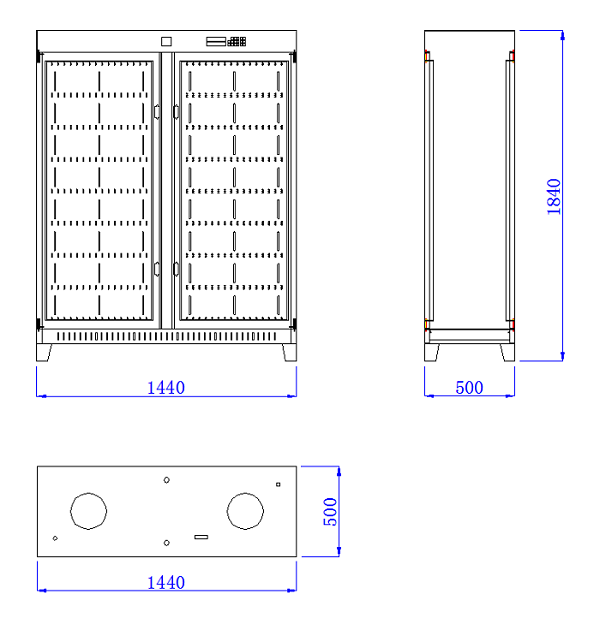

1.Equipment Model and Outline Structure:

Equipment Model:LITH-S1X- 512/5A;

Equipment integrated structure.

Equipment Outline Reference Dimension (mm):

1440(L)*500(W)*1840(H) (For reference only, subject to the actual equipment).

2.Basic Composition of Equipment

The equipment is mainly composed of computer, communication interface and battery detection cabinet. The battery detection cabinet is composed of a clamp and a board body for placing the clamp, a constant current and constant voltage source, a storage control circuit, a sampling circuit, a single chip microcomputer and a control panel.

3.Main Performance of Equipment

1) Each device can conduct constant current and constant voltage charging and constant current discharge tests on 512 batteries that meet the voltage range.

2) The constant current constant voltage power supply is adopted, and the switching from constant current to constant voltage has no impact. It is especially suitable for the charging requirements of lithium-ion batteries.

3) The equipment adopts AVR single chip computer as the control center and cooperates with the peripheral sampling circuit. It can not only be controlled by the superior computer. When the computer is connected to work, it can save the complete charge and discharge curve of all channels, but also be separated from the superior computer and operated through the control panel to complete constant current and constant voltage charging, constant current discharge test, sorting according to time, etc.

4) Each battery has an independent constant current and constant voltage source, which forms a loop and does not affect each other.

5) A light-emitting diode is installed on each battery fixture as the working state display. When the discharge is completed, it can be used to indicate the battery capacity sorting.

6) Detect the voltage of each battery in real time. During charging, charge with constant current first. When the battery voltage reaches the set value, it will be smoothly transferred to constant voltage charging. When the set time or current termination conditions are met, the charging ends. During constant current discharge, when the battery voltage is lower than the set value, the discharge ends and the corresponding battery indicator light is on.

7) With power down protection function, the original workflow can continue to run after an incoming call.

8) The upper computer can set 32 step parameters and 256 cycles. Each upper computer can be connected with 1 ~ 15 sets of single chip microcomputer systems (Less than 10 sets are recommended).

9) Supporting software functions.

① Graphic operation interface is adopted to display data such as voltage, current, time and capacity of each battery, and display corresponding working status and abnormal conditions in various colors;

② Battery capacity indication of any section (Up to 100 sections);

③ The data points can be recorded according to the change conditions of voltage, current and time to form a complete charging and discharging curve data. The time interval of curve data points is ≤ 10 seconds;

④ Battery sorting function under various conditions (Capacity, time, open circuit voltage, discharge platform, etc.);

⑤ Automatically calculate constant current charging ratio, capacity loss, discharge efficiency, average voltage, median voltage and other data;

⑥ Operator authority setting and hierarchical operation;

⑦ It can display charge discharge curve and cycle diagram.

4.Main Technical Parameters

|

Equipment Model

|

LITH-S1X- 512/5A

|

|

Number of Device Channels

|

The whole machine has 512 channels in total

|

|

Workflow Control Mode

|

Whole cabinet control

|

|

Charging Mode

|

Constant current and constant voltage

|

|

Charging Cut-off Conditions

|

Voltage, current, time, capacity

|

|

Discharge Mode

|

Constant current

|

|

Discharge Cut-off Conditions

|

Voltage, time and capacity

|

|

Sampling Inspection Cycle

|

≤10s

|

|

Voltage Measurement Range

|

0 ~ 5V, resolution 1mV

|

|

Battery Voltage Range

|

Charging: 0 ~ 4.5V, Discharging: 4.5 ~ 2.0V

|

|

Constant Voltage Range

|

3~4.5V

|

|

Voltage Accuracy

|

±(0.05%RD+0.1%FS)

|

|

Current Range

|

Charge 0.025-3A, Discharge 0.025-3A, Resolution 1mA

|

|

Current Accuracy

|

±(0.1%RD+0.1%FS)

|

|

Time Frame

|

Any setting within 0 ~ 30000 minutes, time unit:min

|

|

Time Accuracy

|

≤±0.1%

|

|

Fixture Type

|

Cylindrical four wire fixture

|

|

Fixture Spacing

|

35mm

|

|

Fixture Adjustable Height

|

0~90mm

|

|

Support Battery

|

Cylindrical and small square aluminum shell

|

|

Working Power Supply

|

Three phase four wire system, AC380V ±5%, 50Hz, power consumption ≤ 23kw

|

|

Communication Mode

|

RS485, baud rate 57600

|

|

Overall Dimension

|

1440mm(L)*500mm(W)*1800mm(H)

|

|

Work Environment

|

Temperature: 0-40 ℃, relative humidity ≤ 85% RH

|

|

Full Load Operating Current

|

The maximum phase line is 30A, and the maximum zero line is 3A

|

|

Equipment Starting Current

|

The closing moment of air switch is about 60A

|

|

Machine Weight

|

About 250 kg

|

5.Main Configuration Requirements of the System

Minimum configuration of computer system: CPU above P4, memory above 2G, hard disk space above 200G, EGA / VGA color display, one CD-ROM, one mouse, operating system above MicrosoftTM Windows XP, an available RS232 serial communication port and printer supported by Windows. The computer system shall be configured by the user, and the number of computer systems shall be determined according to the actual needs.

Online service

Online service +86 13174506016

+86 13174506016