Automatic Pouch Cell Production Equipment Plant For Li-ion Battery Fabrication

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-ZTH-02Payment:

Credit Card, Paypal, T/T , Western Union, LCShipping port:

Xiamen PortLead Time:

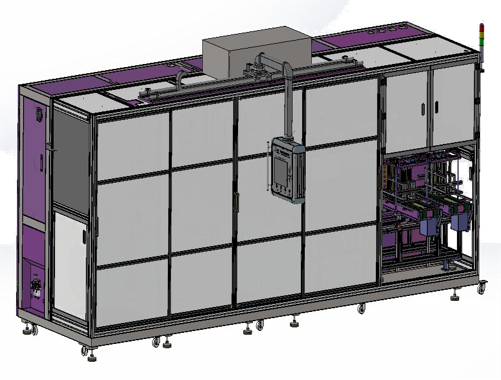

5 daysAutomatic Intermittent Coating And Die Cutting Machine For Pouch Cells Manufacturing

Features

1.Dual Unwinding Mechanism with Quick Roll Change, One for Operation and One for Backup.Specification

|

Project |

Parameter |

|

Production efficiency |

>180PPM |

|

Burr size |

Vas12um ; Vbs12um |

|

Deviation correction accuracy |

≤±0.1mm |

|

Slice forming accuracy |

±0.2mm |

|

Mold Life |

1. After each mold repair, it can be used no less than 1.5 million times;

2. The number of times the mold can be repaired ≥ 10 times; |

|

Material box receiving accuracy |

±0.5mm |

|

Qualification rate |

≥ 99.8% (defects caused solely by the machine) |

|

Crop growth rate |

≥ 98% (faults caused solely by the machine) |

|

Overall dimensions |

W1750mm x L7000mm x H2350mm |

|

Weight/bearing capacity |

About 3000kg; >650Kg/M-2 |

|

Power |

AC380V three-phase; Voltage fluctuation ± 10%; Power: 30KW; Frequency: 50Hz |

|

Compressed air |

0.5-0.7Mpa (5-7kgf/cm2), dosage 400L/min |

|

Project |

Parameter |

|

|

Punching method |

Metal mold punching |

|

|

Material system |

Continuous coating of electrode sheet coil material after slitting, with one side outlet lug |

|

|

Roll diameter |

≤ 600mm |

|

|

Inner diameter of drum |

3"/6" |

|

|

Pole winding error |

士3mm |

|

|

Snake shaped bending error of polar plate |

±1mm/m |

|

|

Height difference of polar wave edge |

<2mm |

|

|

Pole width W |

60~200mm |

|

|

Pole length L |

80~300mm |

|

|

Pole ear length H |

10~30mm |

|

|

Pole ear edge distance Q |

5-20mm |

|

|

Pole ear width P |

10~50mm |

|

|

Pole ear belt material X |

0~2mm |

|

|

Round RB |

2~5mm |

|

|

Round corners RA |

Inner rounded corner |

Outer rounded corner |

Production Assembly Plant

Online service

Online service +86 13174506016

+86 13174506016 Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8613174506016

+8613174506016