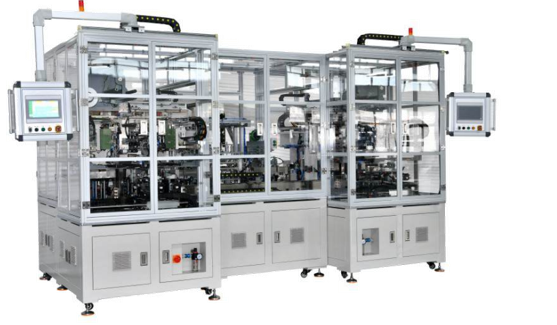

Automatic Pouch Cell Production Equipment Plant For Li-ion Battery Fabrication

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-ZTH-03Payment:

Credit Card, Paypal, T/T , Western Union, LCShipping port:

Xiamen PortLead Time:

5 daysAutomatic Stacking Machine For Pouch Battery Assembly Production

Feature

1.High speed: Linear motor feeding, linear motor driving stacking table movement, achieving high-speed stacking, with a speed of up to 0.3s/pcs

2.The diaphragm is actively unwinded by the servo, and the tension is controlled by the servo torque. The diaphragm buffer and stacking platform move synchronously to supply the diaphragm, preventing it from stretching and deformation.

3.Measures for multi piece leakage: material box swing, segmented brush, robotic arm servo shaking to separate polar pieces, and ultrasonic sensor to detect multi piece leakage.

4.Corner detection of electrode lug: four Corner detection of electrode lug and electrode lug are detected, and defective electrode lug is automatically discharged.

5.The FFU fan at the top of the equipment supplies air, and the industrial dust removal system vacuums multiple workstations such as the material box and positioning, allowing the internal air of the machine to circulate and suck away the floating powder inside.

Specification

|

Locate mode |

Mechanical positioning or CCD positioning |

|

Stacking efficiency |

Single station 0.6 (complete machine 0.3) s/pcs |

|

Auxiliary time |

<10s |

|

Alignment accuracy between electrode and diaphragm |

Center deviation ± 0.3mm |

|

Diaphragm end face alignment accuracy |

±0.3mm |

|

Adjacent pole alignment accuracy |

±0.2mm |

|

Overall alignment accuracy of polar plates |

±0.3mm |

|

Number of laminations |

Can be set within the thickness adaptation range |

|

Outer diaphragm |

Tail roll/no tail roll |

|

Pass rate |

≥99.5% |

|

Utilization rate |

≥98% |

|

Overall dimensions |

W4000mm x L2000mmx H2500mm |

|

Weight/bearing capacity |

About 5000Kg ; >650Kg/M2 |

|

Power |

AC220V single-phase; 10% voltage wave induced soil disturbance; Power: 15KW; Frequency: 50Hz |

|

Compressed air |

0.5~0.7Mpa (5~7kgf/cm2 ), dosage 800L/min |

|

Thickness |

5~20mm |

|

|

Width |

80~200mm |

|

|

Length |

120~300mm |

|

|

Pole length |

10~30mm |

|

|

Polar direction |

On the same/opposite side |

Production Assembly Plant

Online service

Online service +86 13174506016

+86 13174506016 Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8613174506016

+8613174506016