6000A / 8000A Transistor Welding Power Supply Battery Pack Welder Automatic Double Sides Spot Welding Machine

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-ZW-D300Payment:

Credit Card, Paypal, T/T , Western Union, LCShipping port:

Xiamen PortLead Time:

5 daysInverter DC Welding Power Supply Double Side Spot Welding Machine For Automobile Battery Module Pack Welding

Equipment Introduction

Power supply

3 phase~380V±10%/50Hz±10%,

Rated power

50KW(max)

Z1,Z2 Travel Length

0-600mm(max)

Y Travel Length

0-1200mm(max)

X Travel Length

0-40mm

W Shaft angle

0

Welding speed

0.35 S/point;1800-3600PCS/h

Maximum speed of motor transmission

1500mm/s

Maximum load cell (32650)

512 pcs

Number of file groups that can be stored

99

operating system

Industrial computer + man machine picture

Transmission mode

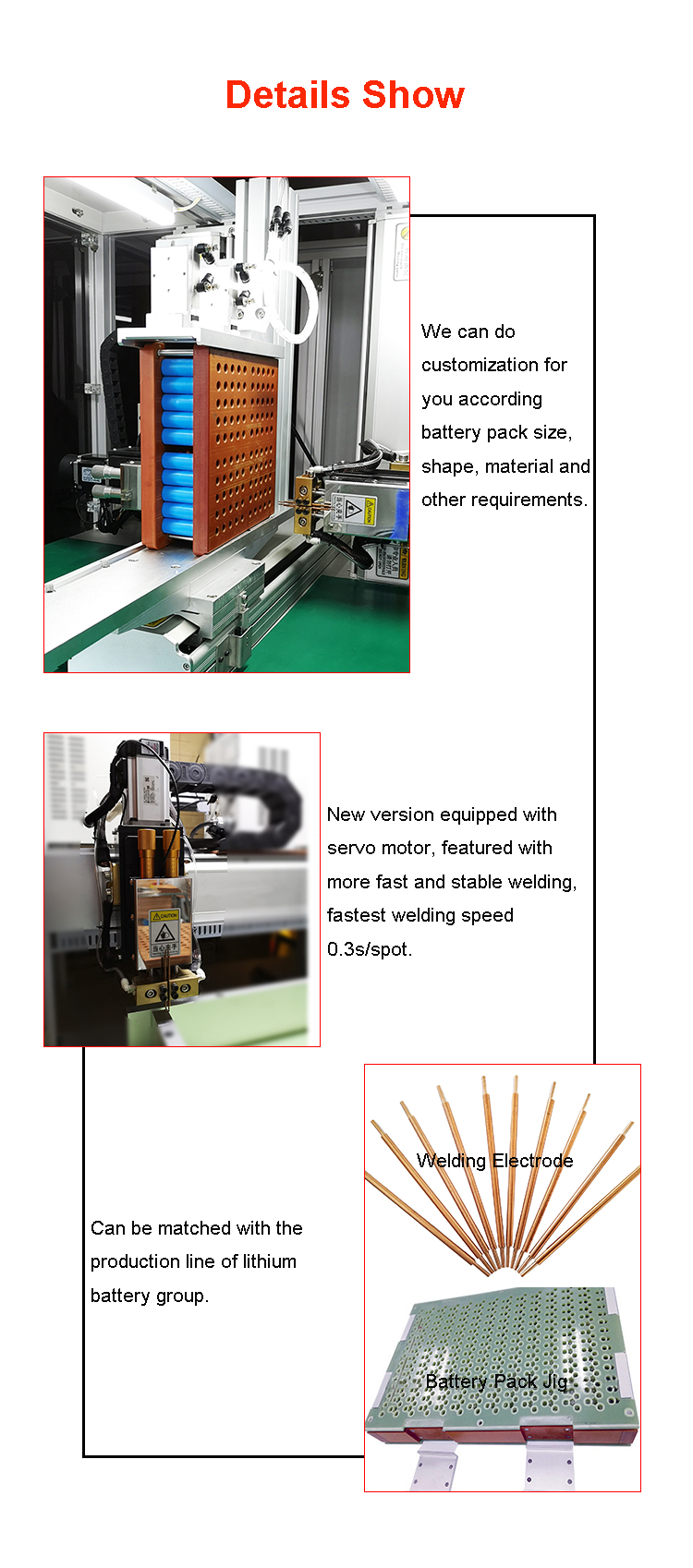

Servo motor + TBI screw + linear guide rail

Spindle electrode

Letron servo motor

Spot welding head

Letron servo motor

Angle adjustment

Closed loop motor

Cooling mode

forced air cooling

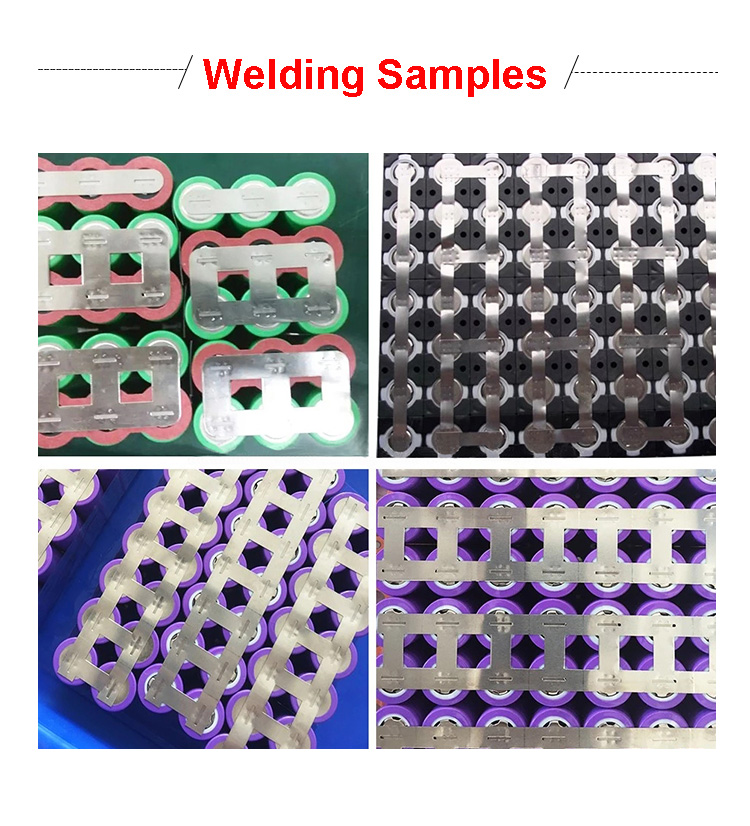

Nickel sheet material

Nickel plated steel or pure nickel

Thickness of Welded Nickel Strip

0.1 mm-0.3 mm;

(above 0.2 mm slot with bump)

External dimension (mm)

1800L*1100W*2000H

Repeat positioning accuracy

±0.02mm

Weight

600kg

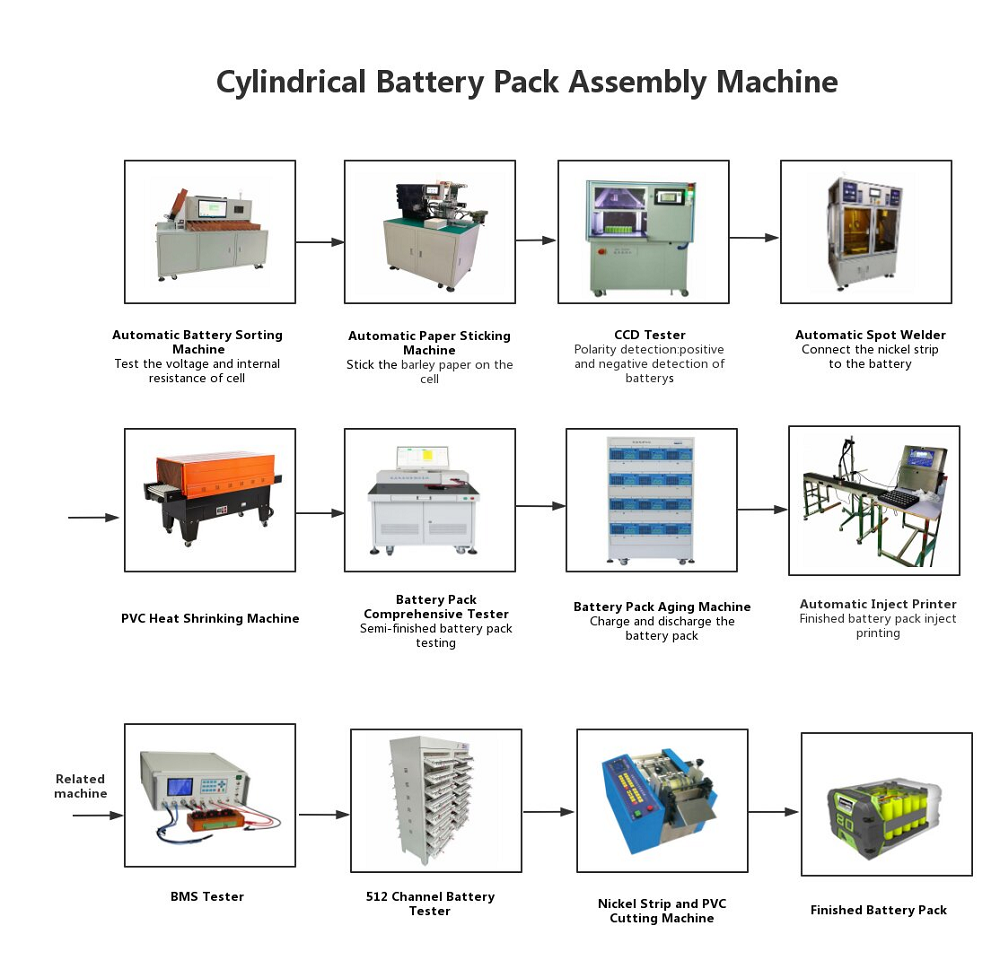

It is suitable for electric vehicle battery pack, automobile battery module, street lamp battery, balance car battery pack, scooter battery pack, mobile power supply, startup battery pack module, power tool battery pack, notebook battery pack, etc! We provide a full series of Energy Storage Battery Assembly for different customers.

Features

1. Support breakpoint start, support automatic start and manual start mode conversion.

2. Simple programming, support any point programming and array programming, can realize jump spot welding, single point, double point mode fast switching, spot welding path optimization, improve efficiency, local disk can store 99 groups of programming files, USB interface can import graphics.

3. The spot welding head takes the center point of two welding pins as the circle center, and the angle is continuously adjustable, which is suitable for spot welding of various special-shaped split connection pieces.

4. The system is divided into operator, administrator, super user and so on. It is convenient to use, manage and maintain butt welding machine.

5. The inverter DC welding power supply has the advantages of stable performance, fast welding speed, constant current working mode and elimination of unstable factors of welding current for a long time.

6. With welding current monitoring system, it can monitor welding current in real time.

7. Spot welding power supply has the function of false welding alarm, which can directly communicate with the motion controller. It can record the false welding position and warn the replacement of welding pin.

8. The welding efficiency is about 8 times that of manual welding, high stability, labor saving and time cost saving.

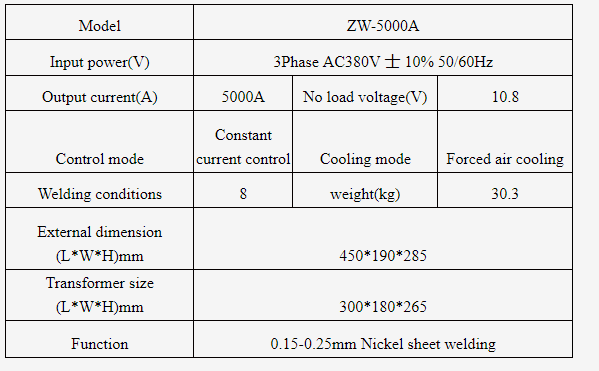

Specifications

Technical parameters of welding power supply

Online service

Online service +86 13174506016

+86 13174506016 Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8613174506016

+8613174506016