|

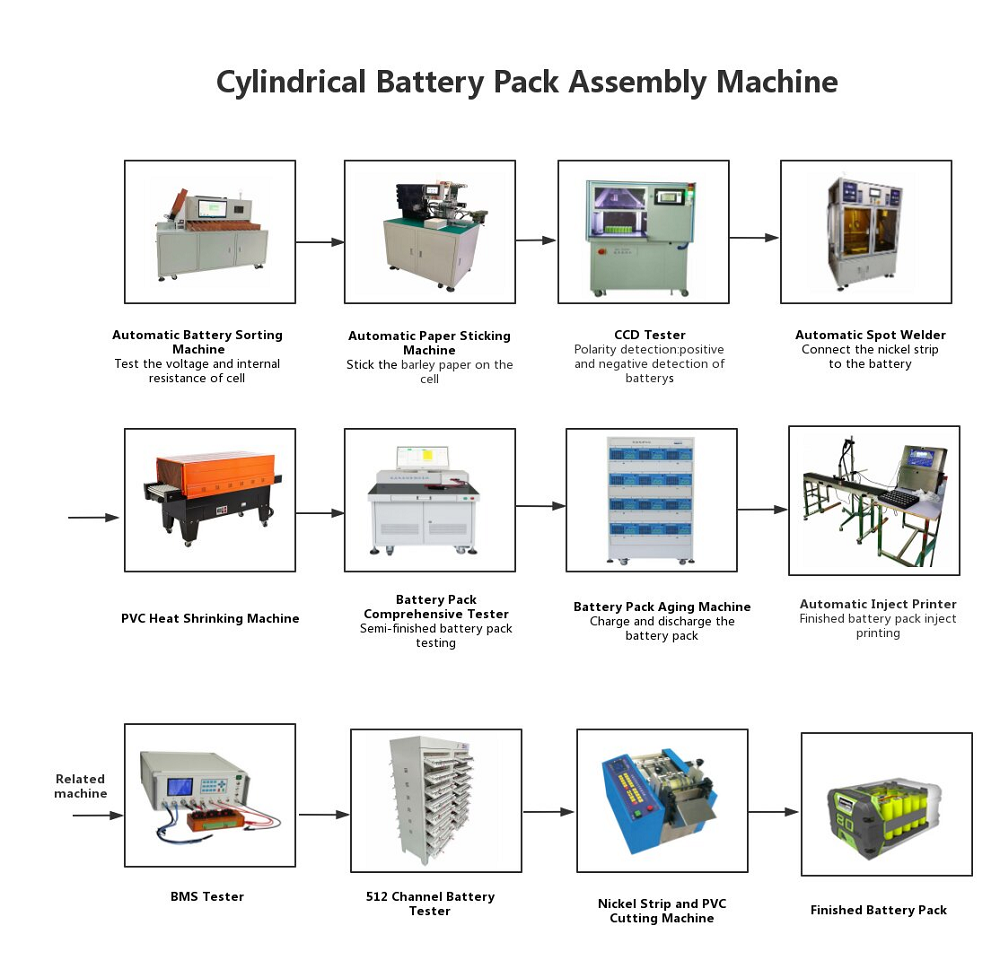

Number of equipment channels

|

512 channels(Single CPU control)

|

|

Constant current range

|

Charging DC 30mA ~ 3A; Discharge DC 30mA ~ 3A, resolution 1mA

|

|

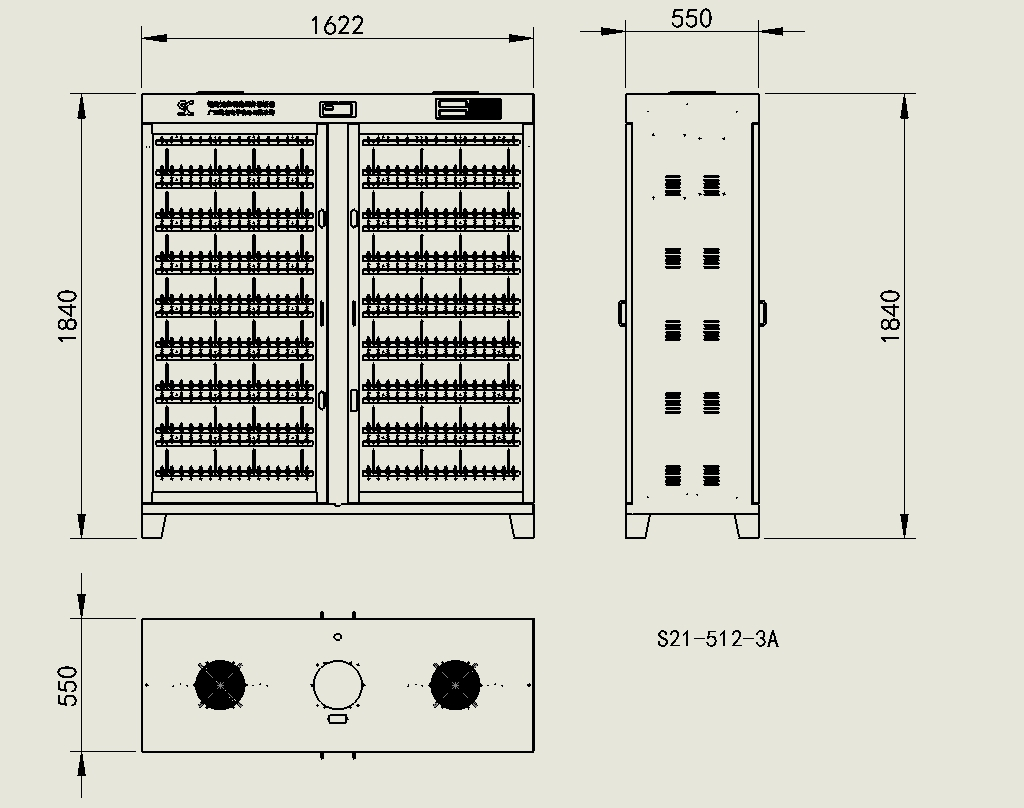

Size

|

550mm W× 1622mm L× 1840mm H

|

|

Chassis color

|

Standard gray black (customizable)

|

|

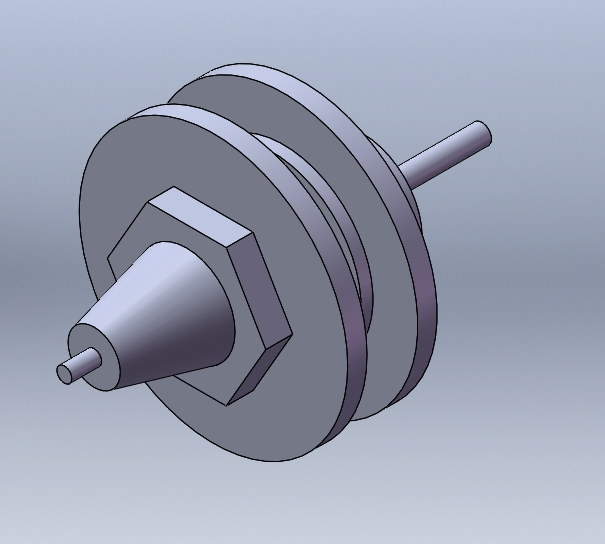

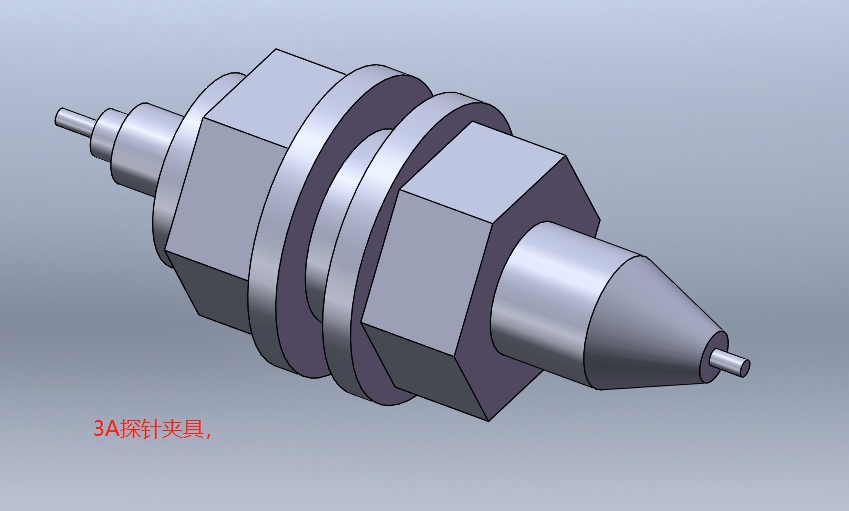

Fixture form

|

Probe clamp

|

|

Support battery specifications

|

Adjustable within 10 ~ 100mm

|

|

Channel control mode

|

Each battery has an independent constant current and constant voltage source, which is stable without impact. Start, stop, pause, continue and protection can be realized

|

|

Each channel has independent constant voltage and constant current hardware control circuit

|

|

Fine tuning and calibration of charging current and discharge current accuracy of each channel

|

|

Working power supply

|

AC380V±10%,50HZ

|

|

Power factor

|

≥0.99

|

|

AC current distortion rate

|

≤2%

|

|

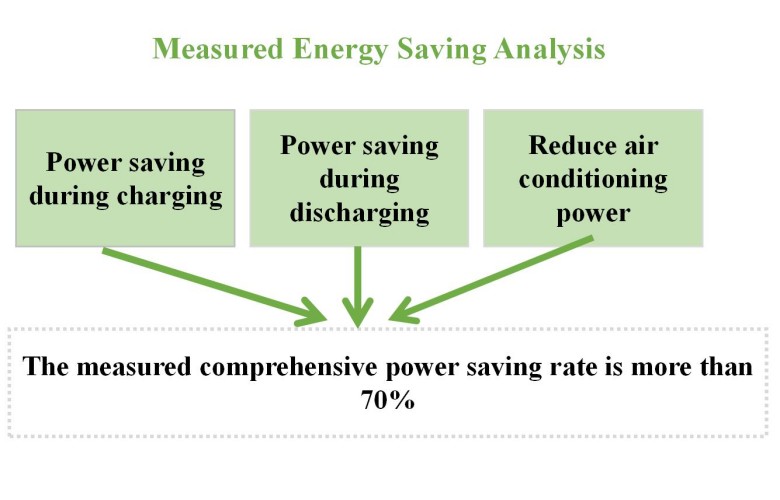

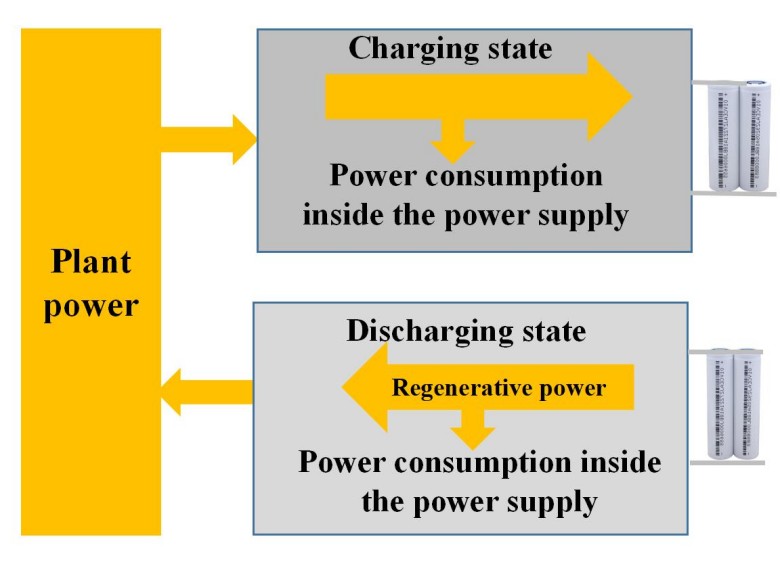

Charging efficiency of the whole machine

|

≥75%

|

|

Feed network conversion efficiency

|

≥70%

|

|

Working power consumption

|

≤9KW

|

|

Equipment failure rate

|

<1%

|

|

work environment

|

Temperature - 10 ~ 40, relative humidity 80%

|

|

Heat dissipation mode

|

Natural air intake and upward exhaust

|

|

Channel parameters

|

|

Voltage measurement range

|

DC 0~5V

|

|

Battery voltage range

|

Charging DC 0 ~ 4.5V; Discharge DC 4.5 ~ 2V

|

|

Constant voltage range

|

DC 2~4.5V

|

|

Voltage accuracy

|

± (1 ‰ reading + 1 ‰ full scale), resolution 1mV

|

|

Voltage stability

|

≤(±1mV)

|

|

Current range

|

Charging DC 30mA ~ 3A; Discharge DC 30mA ~ 3A

|

|

Current accuracy

|

± (1 ‰ reading + 1 ‰ full scale), resolution 1mA

|

|

Current stability

|

≤(±1mA)

|

|

Software function

|

|

control mode

|

Computer control equipment, whole cabinet control, with scanning system

|

|

Communication mode

|

485 serial port communication (baud rate 57600)

|

|

Process settings

|

Up to 32 steps and 256 cycles can be set

|

|

Charging mode

|

Constant current, constant voltage, constant current and constant voltage

|

|

Charging cut-off condition

|

Voltage, current, time, capacity, -△ V

|

|

Discharge mode

|

constant current

|

|

Discharge cut-off condition

|

Voltage, time and capacity

|

|

Protection function

|

Over voltage, under voltage, over current, under current, over capacity protection, power-off protection, data breakpoint recovery

|

|

Time frame

|

0 ~ 999 minutes / work step, and the time unit is min

|

|

Time accuracy

|

≤±1‰

|

|

Sampling inspection cycle

|

≤ 8 seconds

|

|

Battery sorting

|

Sort according to (capacity, time, open circuit voltage, discharge platform, etc.)

|

|

Data processing

|

It can record voltage, current, time and capacity data, automatically calculate constant current charging ratio, capacity loss, discharge efficiency, average voltage, median voltage and other data, and provide data curve and cycle diagram; It can output and generate text, Excel, WODR or MDB database format files

|

|

Basic functions of software

|

1. The software supports various continuation, such as manual pause continuation, software shutdown continuation

Power failure interruption continuation, equipment communication interruption continuation, abnormal stop continuation;

2. It supports bar code scanning, and can scan one-dimensional code and two-dimensional code in order

Code scanning, channel skipping code scanning, loading code scanning and other code scanning methods;

3. Local test detailed data storage, you can view the current test of each channel at any time

Data and historical data, there are two ways to correspond data and curve

Now, it supports exporting excel reports in single or batch form. In addition

You can set the automatic data import at the end of the test as needed.

4. Support capacity sorting and grade sorting of batteries;

5. Support the qualified judgment after the test, according to the specified cycle capacity, voltage and time

Judge the pass / ng result based on the information such as time interval;

6. Support all kinds of work step protection and global voltage, current and temperature abnormal protection (Department)

The sub equipment is equipped with), and carries out abnormal alarm to support overcharge and over discharge protection of battery pack

Protection test;

7. Support channel parallel connection (optional according to equipment);

8. Support company conversion;

9. Support database server background storage or MES docking;

10. Software offline protection;

11. The software provides free upgrades.

|

Online service

Online service +86 13174506016

+86 13174506016