100MWH EV Battery Prismatic Cell Manufacturing Line Machine

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-ZTH-08Payment:

Credit Card, Paypal, T/T , Western Union, LCLead Time:

5 daysPrismatic Cells Automatic Sealing Machine

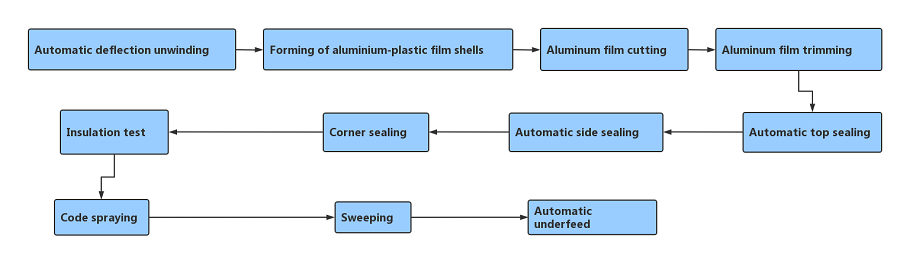

Workflow

Specification

|

Project |

Parameters |

|

Aluminium film punching method |

3-piece film method, top pressing and bottom topping |

|

Film feeding method |

Servo feeding, feeding accuracy ≤ +0.1mm |

|

Punching pattern |

Servo punching shell, adjusting accuracy ≤±0.1mm, can punch single and double pits, simultaneous adjustment |

|

4-corner error of aluminium film punching |

≤±0.15mm |

|

Alignment accuracy of the top and bottom of the aluminium film |

≤±0.5mm |

|

Sealing mode |

Heat encapsulation |

|

Sealing drive |

Servo pressure mode, with cylinders on 2 sides of the head as pressure adjustment |

|

Head temperature control accuracy |

±3°C |

|

Head operating temperature range |

170~200°C |

|

Coding machine |

Inkjet |

|

Production efficiency |

Model 150 ≥12ppm; Model 300 ≥8ppm |

|

Conformity rate |

≥99% |

|

Crop rate |

≥98% |

|

Dimension |

W7000 × L3000×H2350mm |

|

Weight/load |

>750Kg/M2 |

|

Power supply |

AC380V three-phase;voltage fluctuation±10%;power:20KW;frequency:50Hz |

|

Compressed air |

0.5~0.7Mpa ( 5~7kgf/cm2 ), dosage 400L/min |

|

Model |

TMAX-ZTHFZX-150 |

TMAX-ZTHFZX-300 |

|

Cell length |

45~150mm |

120~300mm |

|

Cell width |

35~100mm |

80~200mm |

|

Cell thickness |

3~10mm |

4~12mm |

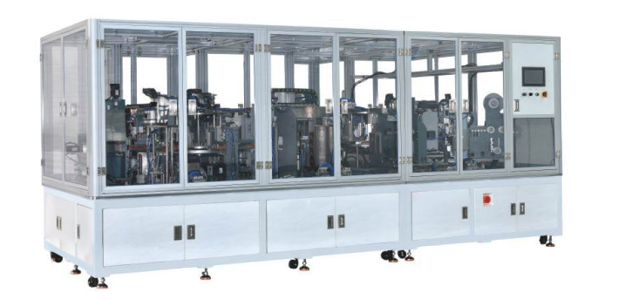

Production Assembly Plant

Images

Online service

Online service +86 13174506016

+86 13174506016 Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8613174506016

+8613174506016