Laboratory Pouch Cell Heat Sealer Machine For Battery Top Side Crimping

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-MSK-111A-EPayment:

Credit Card, Paypal, T/T , Western Union, LCLead Time:

5 daysAutomatic Battery Electrode Separator Layer By Layer Z-Stacking Machine For Pouch Cell Assembly

Introduction

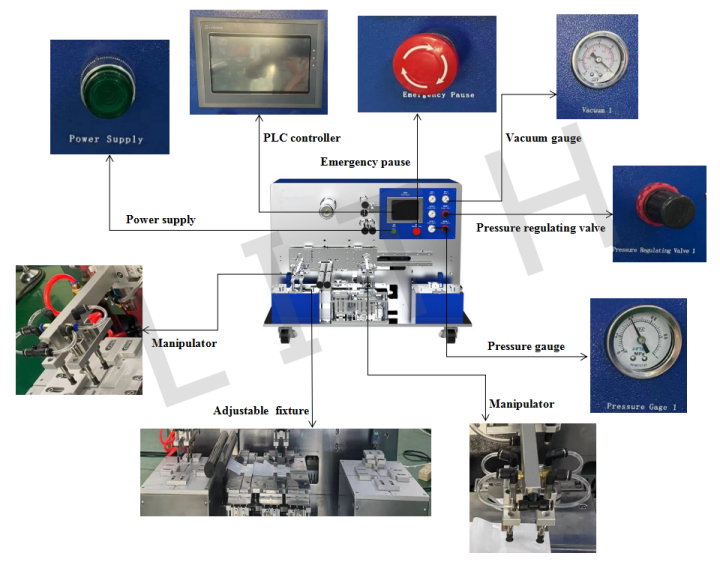

It is mainly used for the assembly of Z-shaped laminations of positive and negative electrodes of lithium battery core and separator.

The device realizes manual loading, subsequent electrode sheet position correction and lamination process using full automation, which is characterized by high lamination efficiency and high lamination accuracy. The device is designed to stack 160 * 160 mm cells at most, and different sizes can be achieved by adjusting the fixture, which is very suitable for the research and development of laminated lithium-ion batteries and sample production. The equipment adopts single cantilever structure design, automatic constant tension control of coiled material separator, and automatic correction control.

Main features

*The number of laminations can be automatically controlled according to preset settings;

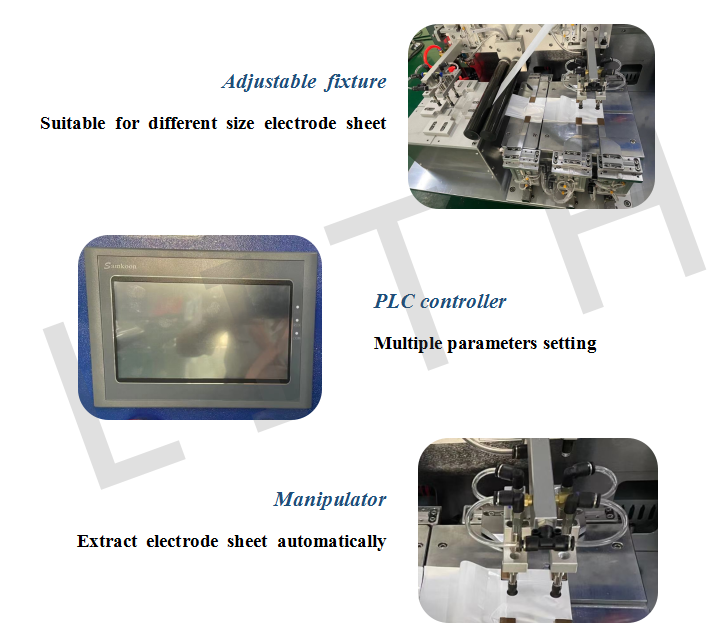

*With compatibility design, the size change of the battery can be realized by adjusting the positioning fixture, and the adjustment range is large;

*PLC control, HMI operation, easy to use and maintain;

*Electrode sheet manual loading, automatic positioning, automatic film suction by manipulator, automatic stacking;

*Coil separator automatic servo constant tension control.

*Separator automatic photoelectric correction control.

*Equipped with automatic ionic water dropping device

Specifications

|

Automatic ionic water dropping device |

Equipped with automatic ionic water dropping device |

|

Stacking mode |

Z-shaped stacking |

|

Operation mode |

manual feeding, manipulator fetching lamination, automatic pulls separator |

|

Stacking accuracy |

Neatness ≤± 0.3mm |

|

Electrode size range |

Min. L40mm *W40mm, Max. L160mm * W160mm, without tabs |

|

Stacking thickness |

Max. 10mm |

|

Stacking layers |

Max. 100 layers can be set |

|

Coil diameter of sperator |

Max 250mm |

|

Separator core |

3-inch core roll, clamped by gas expansion shaft |

|

Tension control |

Automatic servo constant tension control of coiled material separator |

|

Correction control |

Automatic photoelectric correction control of separator |

|

Installation dimension |

L1000mm * W780mm * H750mm |

|

Weight |

About 400Kg |

|

Power supply voltage |

single-phase AC220V ± 10% (110VAC can be customized), frequency: 50Hz/60Hz, power: 0.6KW |

|

Air source |

0.5~0.8MPa compressed air |

|

Environmental requirements |

Recommended operating environment: ambient temperature 25 ± 3 ℃, humidity 30~90RH, no vibration and electromagnetic interference |

Online service

Online service +86 13174506016

+86 13174506016 Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8613174506016

+8613174506016