Laboratory Pouch Cell Heat Sealer Machine For Battery Top Side Crimping

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-TMHPayment:

Credit Card, Paypal, T/T , Western Union, LCLead Time:

5 daysLaboratory Battery Cell Heat Vacuum Film Applicator Coater Machine For Lithium Battery Electode Slurry Coating

Introduction

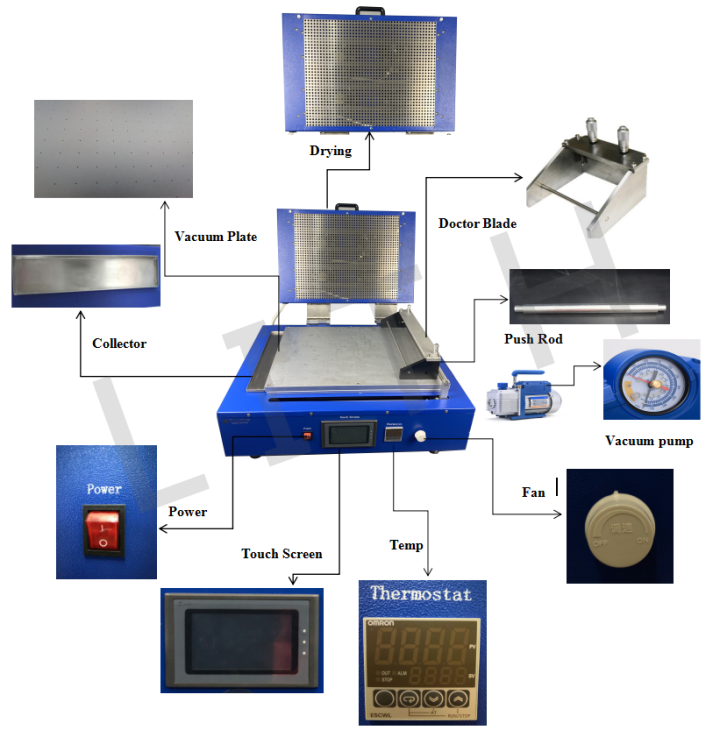

LITH-TMH is a compact tape casting coater with a heating cover designed to produce films with consistent thickness. It has a unique driving system to produce a smooth coating on various types of materials. The flat vacuum chuck is built in to hold the substrate sheet in place, which is particularly useful when making thin film coatings. This product is widely used in various high temperature film research, such as ceramic film, crystal film, battery material film, special nano film.

Features

*Large area uniform heating is adopted to ensure high precision and uniform temperature in the cavity;

*Plate coating, motor driven scraper/film applicator coating, coating speed is stable and adjustable;

*The film coating speed is adjustable, the vacuum aluminum plate can quickly fix or remove copper foil, aluminum foil, etc., and the vacuum pump is included for your immediate use;

*One film applicator is included, high precision and coating thickness adjustable;

*It can be used in glove box, easy to operate, small size and space saving;

*Upgraded PLC touch screen control, easy to set parameters.

Specifications

|

Model |

TMH-100-250 |

150-250 |

250-300 |

250-350 |

250-500 |

250-800 |

|

Effective coating area(mm, size can be customized) |

100 x 250 |

150 x 250 |

250 x 300 |

250 x 350 |

250 x 500 |

250 x 800 |

|

Stroke length (mm, length adjustable) |

10 - 250 |

10 - 250 |

10 - 300 |

10 - 350 |

10 - 550 |

10 - 800 |

|

Vacuum chuck dimensions (mm, W*L, , size can be customized) |

100 x 365 |

150 x 365 |

250 x 400 |

250 x 450 |

250 x 650 |

250 x 900 |

|

Power supply |

110VAC or 220VAC |

|||||

|

Coating speed |

0 - 120 mm/sec variable; accuracy: 10mm/sec (The coating speed range can be customized) |

|||||

|

Vacuum pump (Optional) |

One oil free vacuum pump |

|||||

|

Film applicator |

One standard film applicator is included as below: *Analog film applicator with fix coating width *0~3mm gap/coating thickness adjustable *Coating accuracy: ±3μm |

|||||

|

Optional parts: Digital micrometer Adjustable width Different gap/coating thickness |

||||||

|

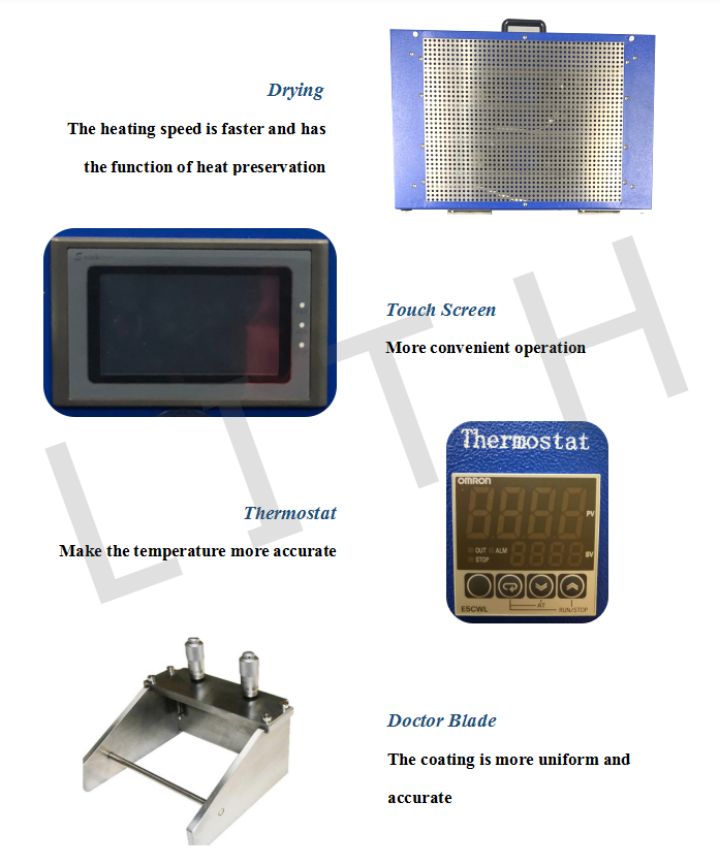

Heating function (selectable) |

Platen heating(standard)

1. Heating on the vacuum chuck/coating plate 4. You can choose to have the cover or not, with cover, it will faster the drying speed as it will keep the |

|||||

|

Top cover heating 1. Heater pre-installed on the top cover 2. Built in digital temperature controller with accuracy of +/-1°C 3. Suspension support helps open cover easily and safely 4. Max. Heating Temp: 200°C |

||||||

|

Surface finish |

▽10 |

|||||

|

Surface roughness |

Ra0.1 |

|||||

|

Vacuum board material |

5052 Aluminum alloy |

|||||

|

Compliance |

CE Certificate |

|||||

|

Warranty |

One year limited warranty with lifetime support |

|||||

Online service

Online service Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8618659217588

+8618659217588