Laboratory Pouch Cell Heat Sealer Machine For Battery Top Side Crimping

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-VS-24BPayment:

Credit Card, Paypal, T/T , Western Union, LCLead Time:

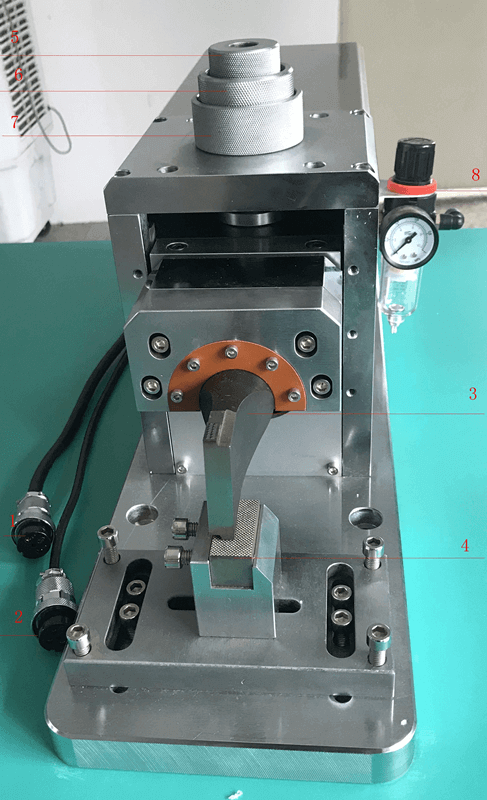

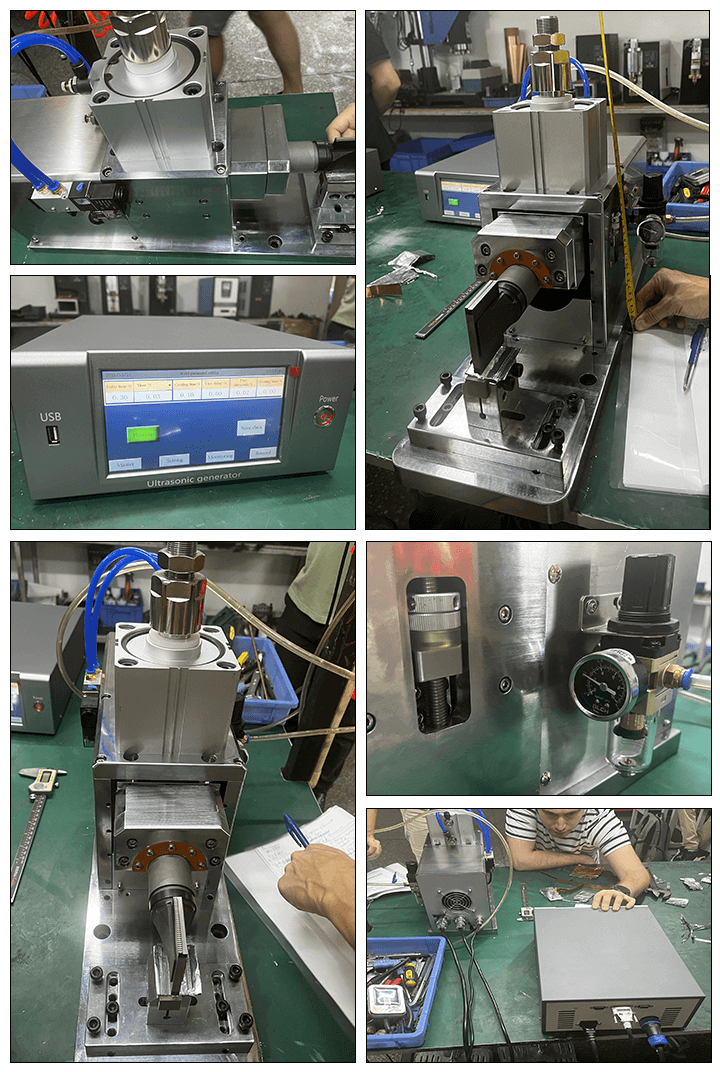

5 days2000W 40KHz Battery Ultrasonic Metal Spot Welder For Pouch Cell Tab Welding

Introduction

Ultrasonic spot welding machine is an advanced high-tech equipment that converts high-frequency electric energy into a mechanical vibration energy through a transducer and acts on the bases material, to generate high-frequency friction between the surfaces of the two work-pieces until the surfaces of the two bases material are heated and welded together. It can perform spot-like and strip-shaped soldering on thin materials such as copper, silver, chrome, nickel and other conductive metals. It can be widely used in lead wire of silicon controlled chip leads, fast-fuse holders, electrical lead terminals, lithium ion, nickel point-like, strip-shaped soldering of poles such as hydrogen and nickel-cadmium batteries.

The welding process of an ultrasonic spot welder is a mechanical process in which no current flows through the material and no melting occurs. Moreover, the same or the different alloy materials can achieve the ideal welding, the electrical and the thermal properties are not achieved by other processes. Compared with fusion welding, ultrasonic welding machine has low electrical consumption, long life and low labor intensity.

Specifications

|

Features |

Preset welding programs selectable for Al and Cu (Note: Welding power can be readjusted to fit the needs for welding other types of metals such as Au, Fe, Ni, Ag...). |

|

Input Voltage |

AC 110V or 220V +/-10%, 50/60Hz |

|

Max.Power.Consumption |

3600W |

|

Welding time |

0.5~2S |

|

Control method |

CPU control |

|

Gas supply source |

≥0.5MPa |

|

Welding Area |

4mm(L) x 4mm(W) or customized size |

|

Welding Head |

The welding heads and welding bases are included for welding both aluminum & copper current collectors from 2 to 60 layers |

|

Ultrasonic Frequency |

20K Hz |

|

Product Dimensions |

1. Controller: 360mm(L) x 480mm(W) x 200mm(H)

2. Welder: 200mm(L) x 460mm(W) x 270mm(H) |

|

Net Weight |

70kg |

|

Compliance |

CE Certificate |

|

Warranty |

Two Year limited warranty with lifetime support |

|

Application Notes |

Nickel and Aluminum Tabs can be welded onto different types current collecting substrates (Aluminum or Copper) when making battery electrodes. |

Online service

Online service +86 13174506016

+86 13174506016 Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8613174506016

+8613174506016