100MWH EV Battery Prismatic Cell Manufacturing Line Machine

Contact Person:Louis Yang Email: Louis@chinabatterymachine.com Tel:+86 13003860308 Whatsapp: +86 13003860308 Wechat:18659217588

Email: Louis@chinabatterymachine.com

Tel:+86 13003860308

Whatsapp: +86 13003860308

Wechat:18659217588

Item No.:

LITH-FXZYPayment:

Credit Card, Paypal, T/T , Western Union, LCLead Time:

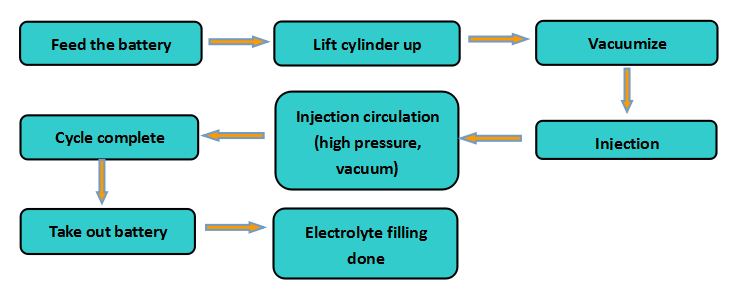

5 daysVacuum Electrolyte Filtration Filling Machine For Prismatic Battery

Introduction

*Multi stage filtration device and special material adsorption system are adopted to effectively ensure smooth valve pipeline, protect the vacuum pump from corrosion damage and block the pump blade from being able to start vacuumizing.

Specifications

|

Filling accuracy |

±1% |

|

Filling volume |

0~250ml adjustable |

|

Vacuum |

During electrolyte injection, the vacuum pressure shall be kept above -98kpa ( vacuum pump provided by the customer). |

|

Parameter setting |

The vacuumizing time, low vacuum degree, liquid injection standing time, pressure and time can be adjusted. |

|

Machine frame |

The joint of liquid injection tank body is made of stainless steel, the hose is made of corrosion-resistant PE hose, the body is made of 6 series aluminum alloy, and the whole machine is corrosion-resistant. |

|

Nitrogen |

≥0.4MPa |

|

Voltage |

AC220V |

|

Power |

1.5KW |

|

No. |

Item name |

Quantity |

Unit |

|

1 |

Electrolyte injection station |

1 |

Set |

|

2 |

Automatic liquid injection mechanism |

2 |

Set |

|

3 |

Electric metering pump (ceramic pump) |

1 |

Set |

|

4 |

Vacuum pump or pipeline vacuum (- above 98kpa)→not included in the standard package |

1 |

Set |

|

5 |

Bracket |

2 |

Set |

|

6 |

Battery positioning mechanism |

2 |

Set |

|

7 |

Pressure nozzle mechanism of injection nozzle |

2 |

Set |

|

8 |

Electrolyte transfer tank |

1 |

Set |

|

9 |

Electrolyte filtration system |

1 |

Set |

Product Image

Online service

Online service +86 13174506016

+86 13174506016 Louis@chinabatterymachine.com

Louis@chinabatterymachine.com +8613174506016

+8613174506016